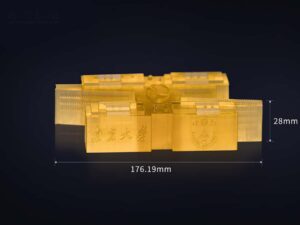

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

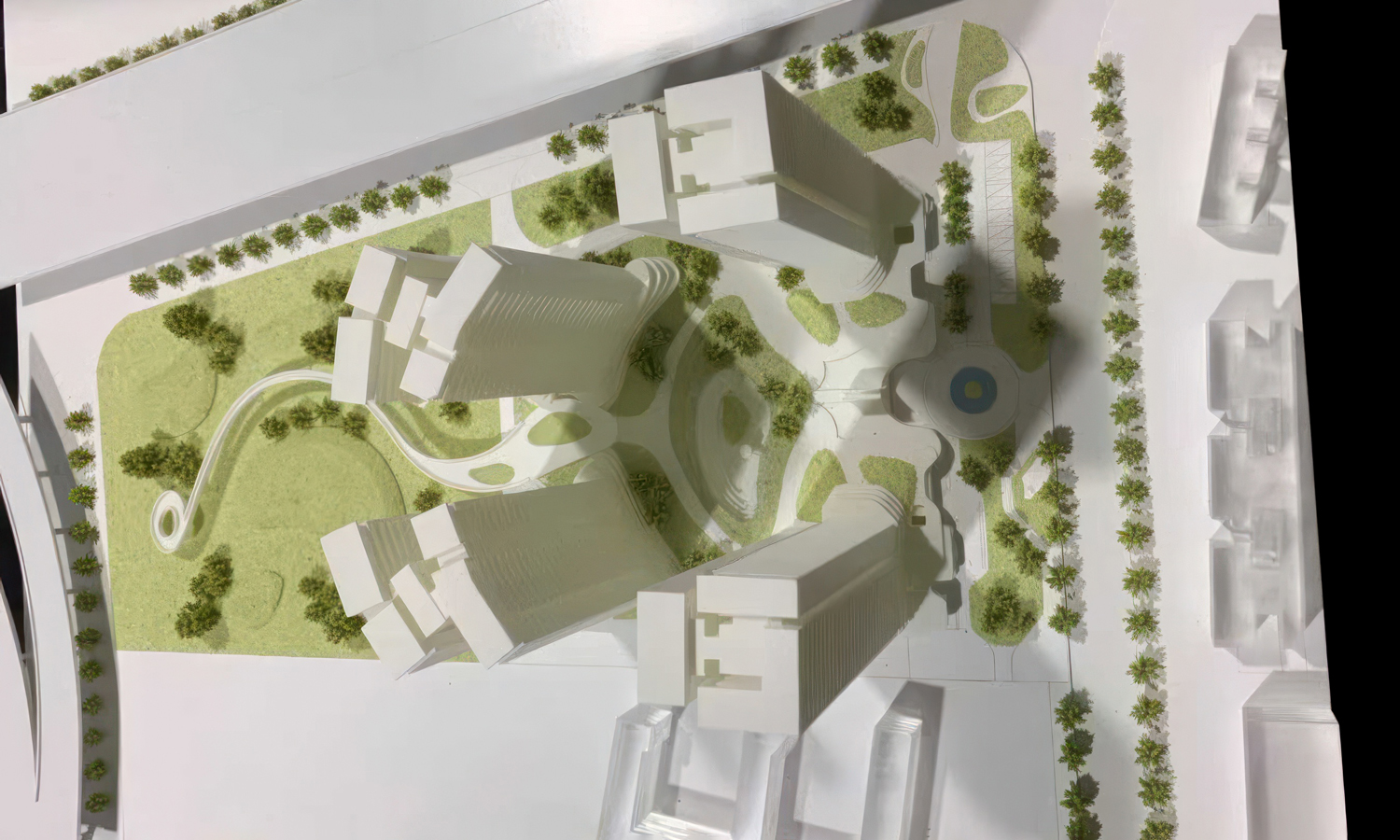

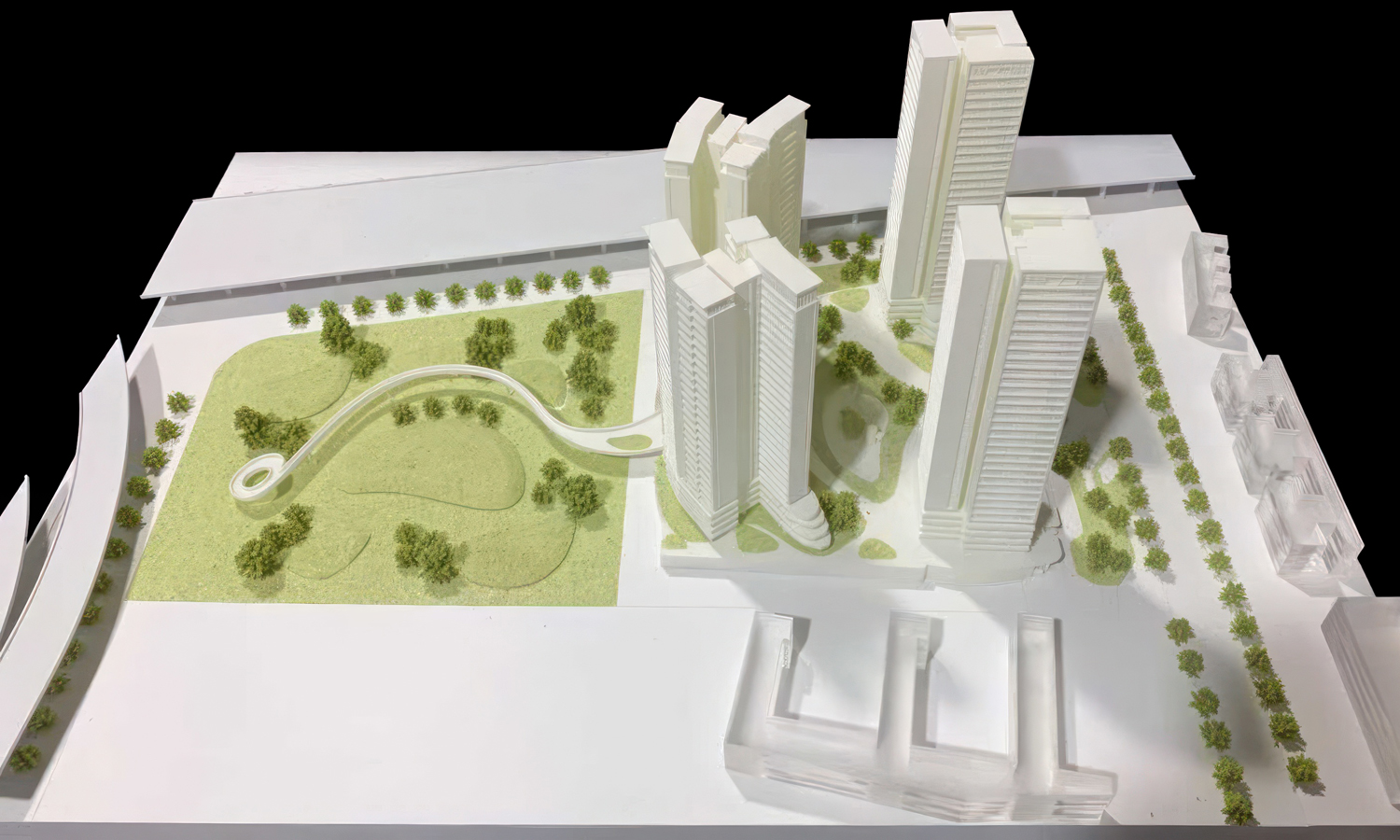

This architectural scale model masterfully demonstrates the balance between high-density urban living and organic green space. By utilizing advanced SLA (Stereolithography) 3D printing, the project translates complex digital geometries into a precise physical form that highlights both verticality and pedestrian connectivity.

The design features four primary residential towers characterized by a rhythmic, “serrated” balcony pattern. To achieve the sharp edges and smooth surface finish required for such intricate detail, the towers were printed using SLA Generic Resin. This material provides a clean, matte white aesthetic that catches natural light, emphasizing the architectural “mass” and the stepped profiles of the skyscrapers.

In contrast, the lower-tier peripheral buildings and site context were fabricated with SLA Clear Resin. This material choice creates a sophisticated visual hierarchy; while the main towers stand out as solid landmarks, the translucent surrounding structures appear “ghost-like.” This effectively dematerializes the context, allowing the viewer to focus on the core design while still understanding the project’s spatial relationship with its environment. The central ground plane further enhances the composition, featuring fluid, 3D-printed walkways and a circular water feature that serve as the project’s communal heart.

Bringing such high-fidelity designs to life requires professional-grade precision and a diverse material library. FacFox’s 3D printing services specialize in high-resolution SLA manufacturing, offering everything from industrial-grade Generic Resins for structural massing to polished Clear Resins for transparent facades. Whether you are creating a quick massing study or a final competition-ready masterpiece, FacFox provides the speed, accuracy, and expert post-processing needed to elevate your architectural vision.

Solution

- Step 1: The architectural CAD files were analyzed and divided into distinct components based on their intended material properties, separating the primary towers from the surrounding context and site base.

- Step 2: Digital 3D models were optimized for SLA (Stereolithography) printing, where support structures were strategically placed to ensure the stability of the serrated balcony details and overhangs.

- Step 3: The four primary towers were printed using SLA Generic Resin, while the lower-profile ancillary buildings were simultaneously fabricated using SLA Clear Resin to create the desired visual contrast.

- Step 4: Once the printing was completed, the parts were removed from the build plate and submerged in an isopropyl alcohol (IPA) bath to ensure all uncured resin was thoroughly stripped away.

- Step 5: The support structures were carefully detached by hand, and the contact points were sanded to a smooth finish to maintain the seamless aesthetic of the tower facades.

- Step 6: The clear resin components were subjected to a specialized post-curing process and fine-polishing to enhance their transparency and “ghost-like” appearance.

- Step 7: The landscape and site base were prepared using traditional modeling techniques, including the application of grass flocking and the placement of scaled vegetation.

- Step 8: All 3D-printed resin components were precisely aligned and bonded to the baseplate, completing the assembly of the multi-material scale model.