CNC Milled EPP Foam Glider Wing for Model Airplane

Posted on 2024-01-23 in Aerospace · 航天

Gallery

About Project

Elevate your model airplane performance with FacFox’s CNC-milled EPP foam glider wings, built for unmatched precision, lightness, and lift.

Experience the Sky like Never Before

- Effortless Glide: Our symmetrical airfoil design generates exceptional lift at low speeds, ensuring smooth, graceful flights for gliders of all sizes.

- Stable Control: We’ve meticulously engineered a dihedral angle to enhance roll stability, keeping your aircraft steady even in turbulent conditions.

- Exceptional Maneuverability: Precise washout angles prevent tip stall, allowing for confident control and playful aerobatics.

Beyond the Wing

But FacFox goes beyond just wings. We offer comprehensive model airplane CNC milling services, including:

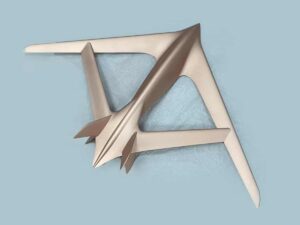

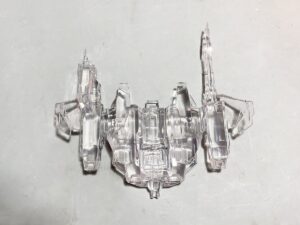

- Custom Carbon Fiber Skeletons: Upload your blueprints and let us bring your vision to life with laser-cut carbon fiber skeletons for precise assembly with your EPP foam wings.

- Unmatched Accuracy: Our state-of-the-art CNC machines guarantee micrometer-level precision for every cut, ensuring a perfect fit and optimal performance.

- Unleash Your Creativity: We cater to all skill levels and design preferences. Whether you’re a seasoned pro or a curious beginner, FacFox helps you make your dream model airplane a reality.

Don’t settle for anything less than perfection. Choose FacFox and craft a glider that soars above the competition. Visit our website today to learn more and get a quote!

Solution

- Stage 1: Dimensional Acquisition and Digital Blueprint Integration. The initial step involves precise measurement of the EPP block using calibrated calipers. This crucial data ensures seamless compatibility with the chosen wing design. Subsequently, the client-provided blueprint, a digital map of the desired aerodynamic properties, is uploaded to the 5-axis CNC machine. This acts as the guiding script for the subsequent sculpting process.

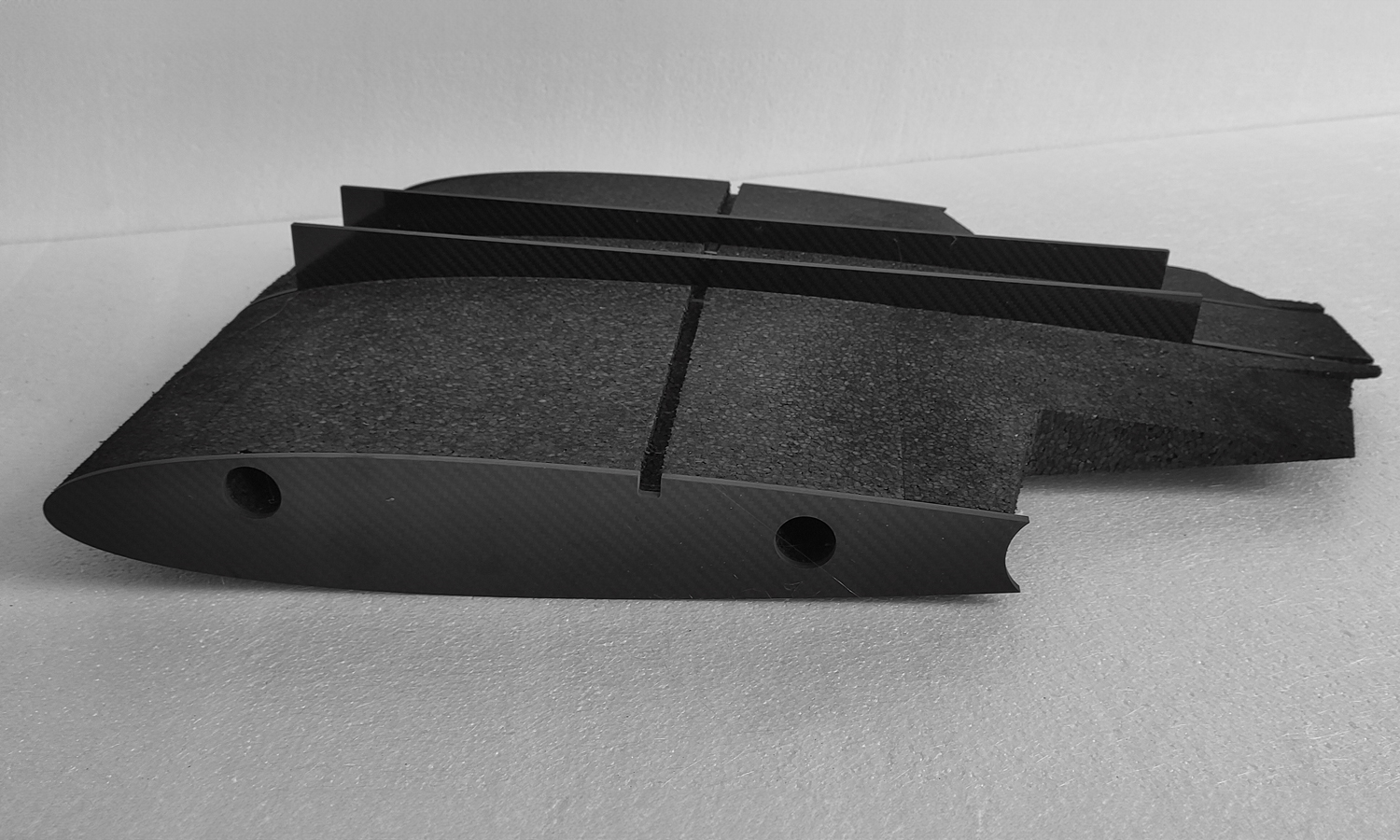

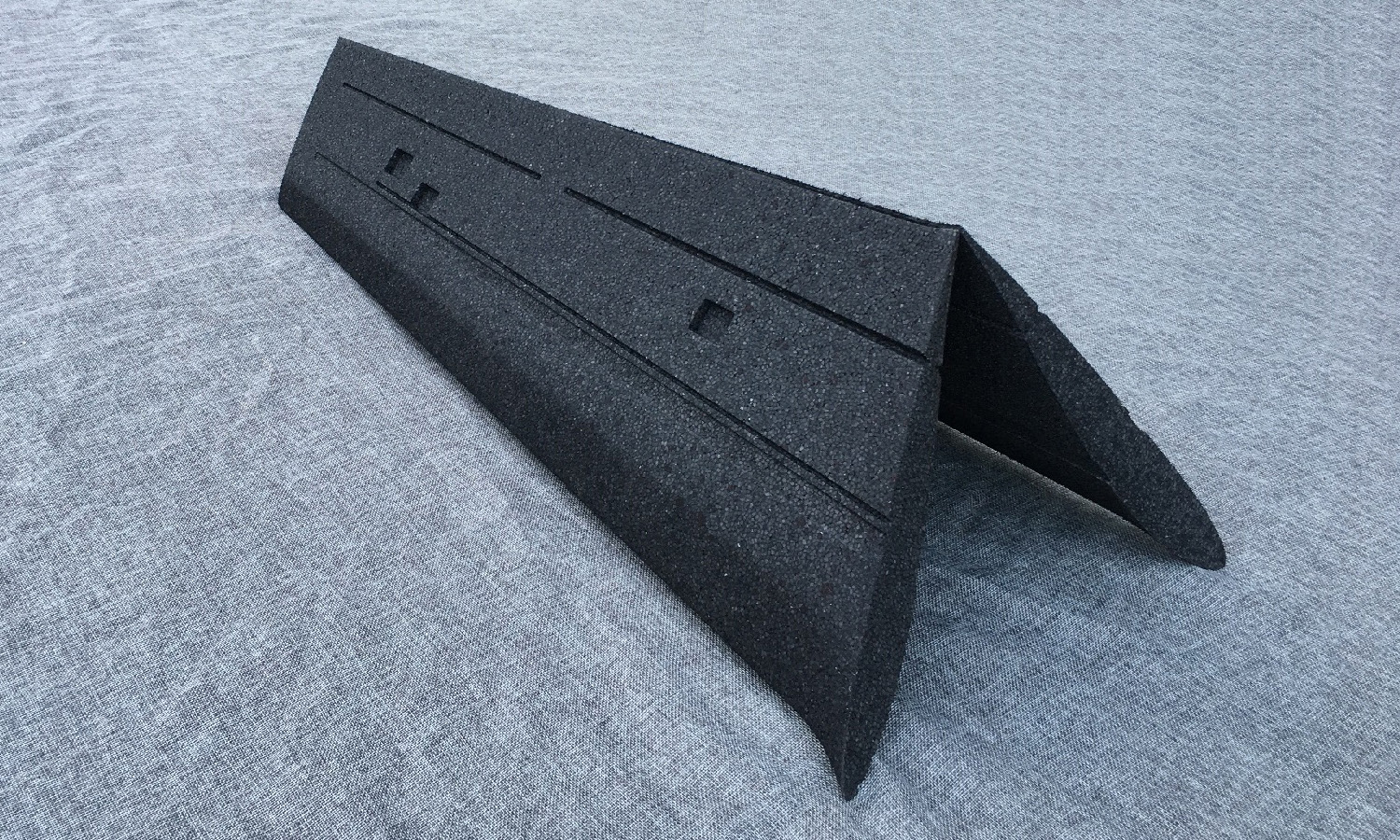

- Stage 2: CNC-Sculpted Aerodynamic Form. Guided by the digital blueprint, the CNC machine wields a custom-designed end mill with surgical precision. Millimeter by millimeter, the EPP surrenders to the programmed commands, revealing the meticulously contoured wing profile. This stage births the core aerodynamic features – the symmetrical airfoil for efficient lift generation, the dihedral angle for inherent roll stability, and the washout angle for stall prevention at high angles of attack.

- Stage 3: Surface Perfection and Optional Structural Reinforcement. Skilled technicians meticulously hand-sand the sculpted wing to achieve a pristine, aerodynamically optimized surface. This minimizes drag and maximizes glide performance. Optionally, for enhanced strength and rigidity, a laser-cut carbon fiber skeleton, precisely tailored to the client’s specifications, is bonded to the EPP core using aerospace-grade epoxy. This creates a lightweight yet robust framework, ideal for demanding flight conditions.

- Stage 4: Rigorous Quality Control and Flight-Readiness Assessment. The completed wing undergoes a comprehensive quality control inspection. Every detail, from dimensional accuracy to surface finish, is scrutinized against FacFox’s uncompromising standards. Only wings passing this rigorous examination are deemed worthy of gracing the skies.