Gallery

About Project

Imagine, if you will, a sink sculpted not from porcelain, but from the purest, most protective foam. This isn't the realm of daydreams, but the innovative reality of CNC-milled EPP foam, and FacFox is proud to present a stunning example: the packing enclosure tank.

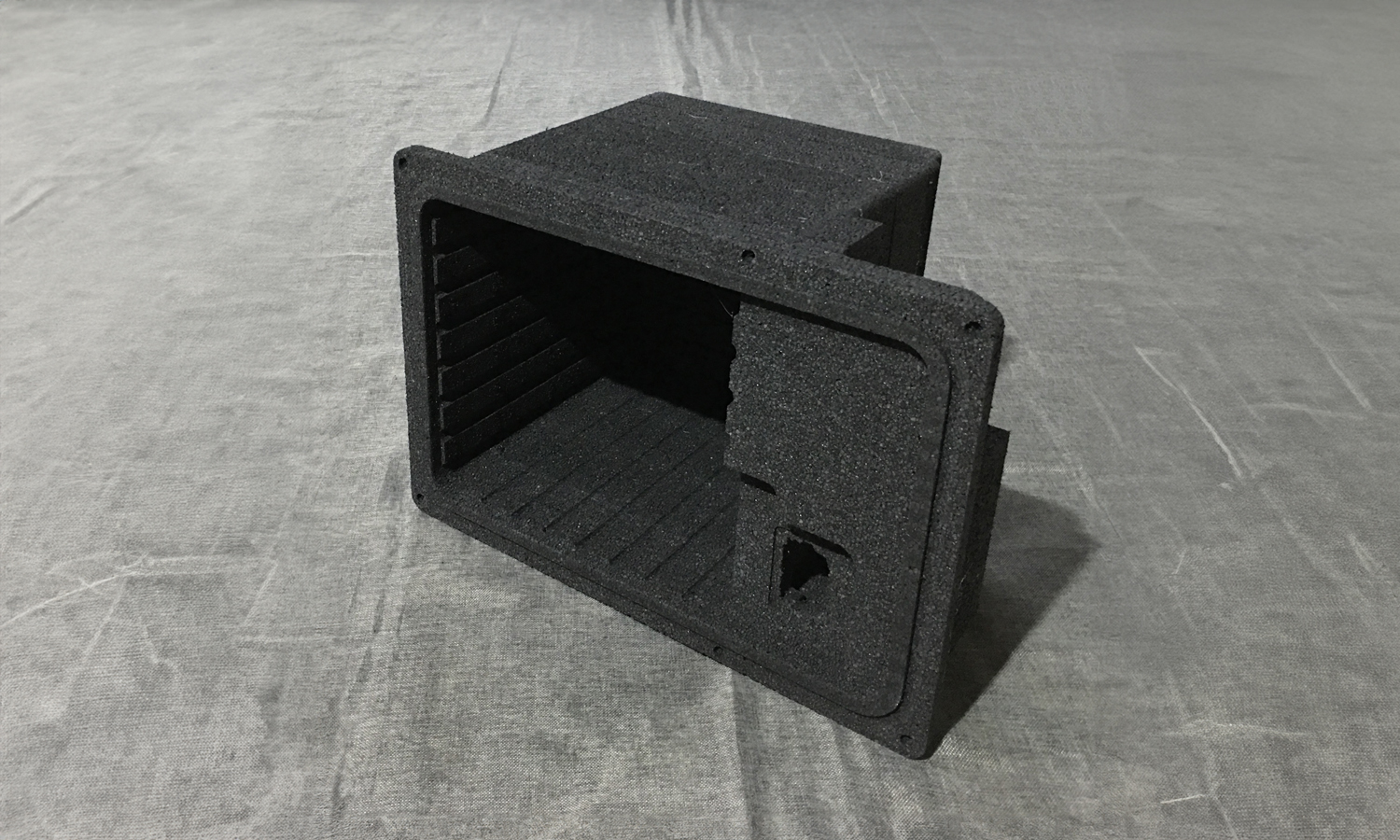

Picture this sleek, sink-like vessel, crafted with precision and care. Its smooth exterior curves gently, offering a haven for your precious products. But this isn't just any foam container. One corner dips away in a playful cuboid, adding a touch of intrigue space.

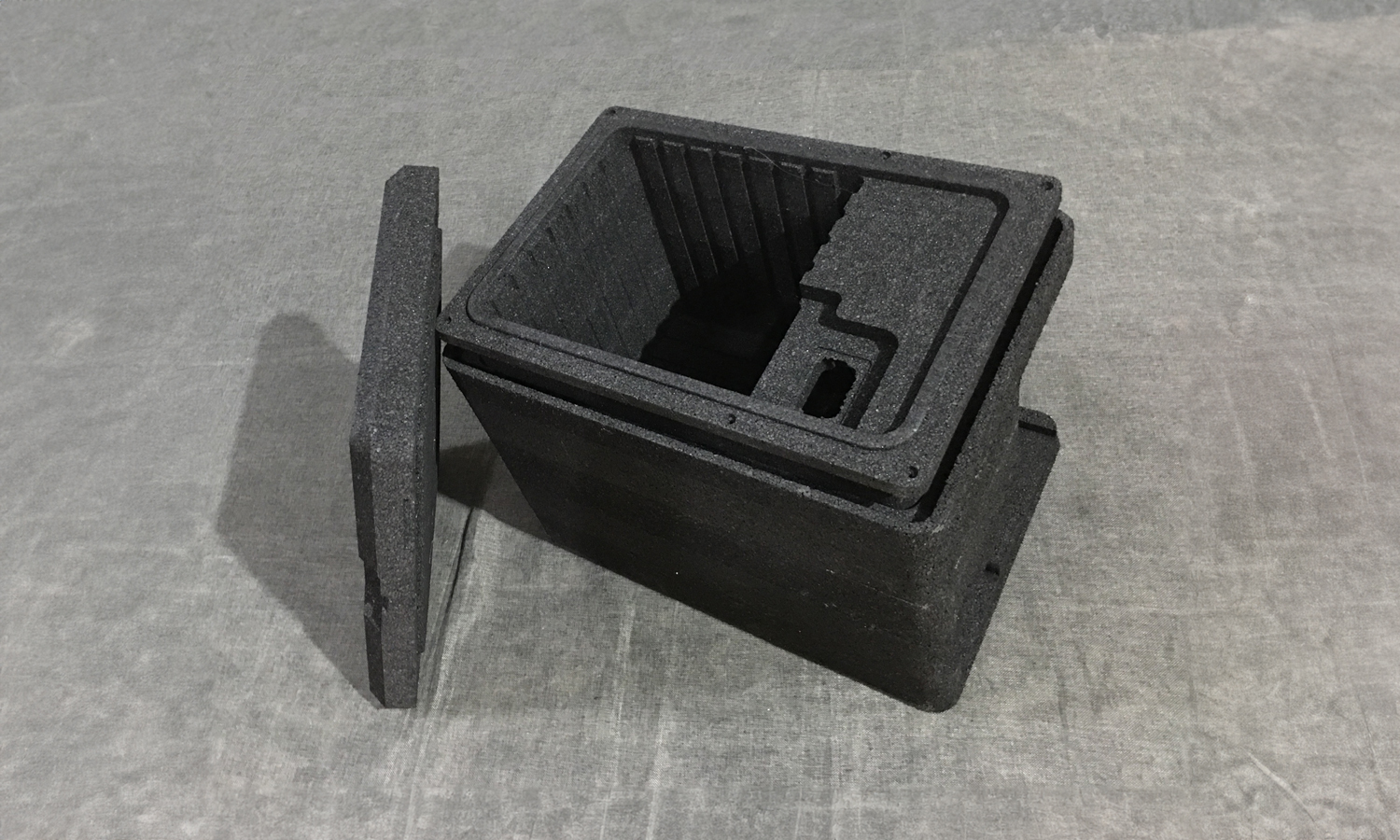

On the upper face, a broader edge rises like a protective lip, cradling a clever little hollow ŌĆō the perfect perch for tools, manuals, or any other essentials your clients might need. And to keep everything safe and sound, a snug foam cover sits atop, like a gentle lullaby for your precious cargo.

But the beauty of this tank lies not just in its form, but in its function. Peer inside, and you'll be met with a network of strategic embossments, meticulously carved into the foam walls. These aren't mere decorations; they're the unsung heroes of protection, gripping your products with a gentle yet firm embrace, ensuring they arrive at their destination just as pristine as they departed.

This tank is a testament to the power of CNC milling and the versatility of EPP foam. It's lightweight yet sturdy, customizable to your every need, and gentle enough to cradle even the most delicate of treasures.

At FacFox, we're passionate about turning foam into functional magic. Our CNC milling expertise and dedication to quality ensure that every EPP foam creation we produce is a masterpiece of protection and precision. So, whether you need a sink-like tank, a custom-shaped cushion, or anything in between, FacFox is your one-stop shop for packing innovation.

Don't settle for generic, off-the-shelf solutions. Let FacFox craft the perfect foam enclosure that reflects your brand, protects your products, and delights your customers. Contact us today and experience the FacFox difference!

Solution

- Step 1: A digital blueprint of the tank, including its sink-like shape and cuboid recess, was meticulously uploaded to the CNC milling machine.

- Step 2: EPP foam blocks, chosen for their lightweight strength and protective qualities, were precisely clamped onto the machine’s bed.

- Step 3: Guided by the blueprint, the milling head is carved away at the foam, meticulously sculpting the tank’s smooth curves, recessed corner, and upper edge with its hollow.

- Step 4: Inside the tank, strip-like embossments were delicately etched into the walls, transforming them into secure cradles for the protected items.

- Step 5: Once complete, the CNC machine gently released the finished tank, its sleek form now ready to embrace its protective destiny.

- Step 6: A separate piece of foam, pre-cut to match the tank’s upper edge, was nestled into place, forming a snug and protective cover.