- SLA 3D Printed Full-scale Sitting Cat Resin Statues

- FDM 3D Printed Pallet Jack Forklift Toy Functional Model

Material Resin

Quantity 2 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

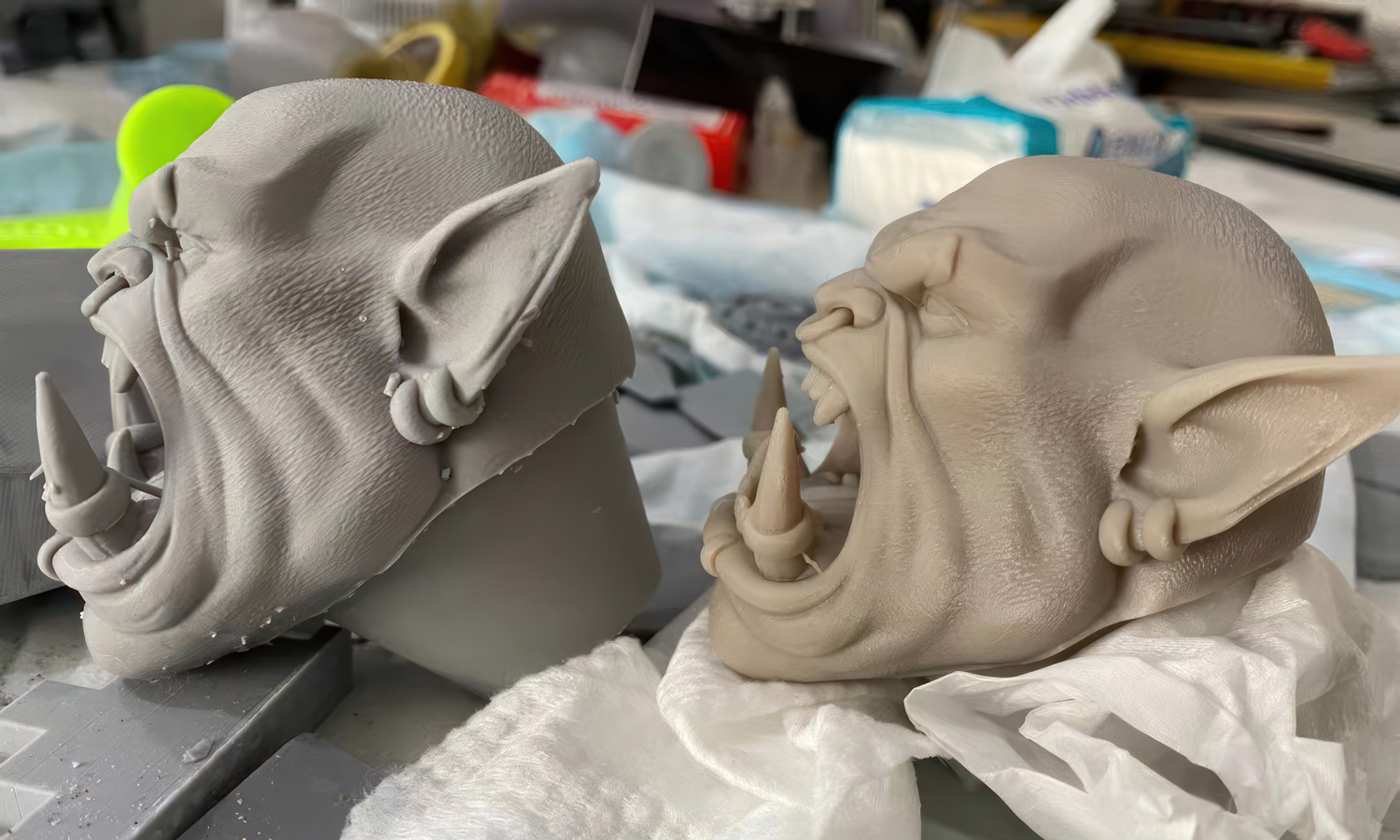

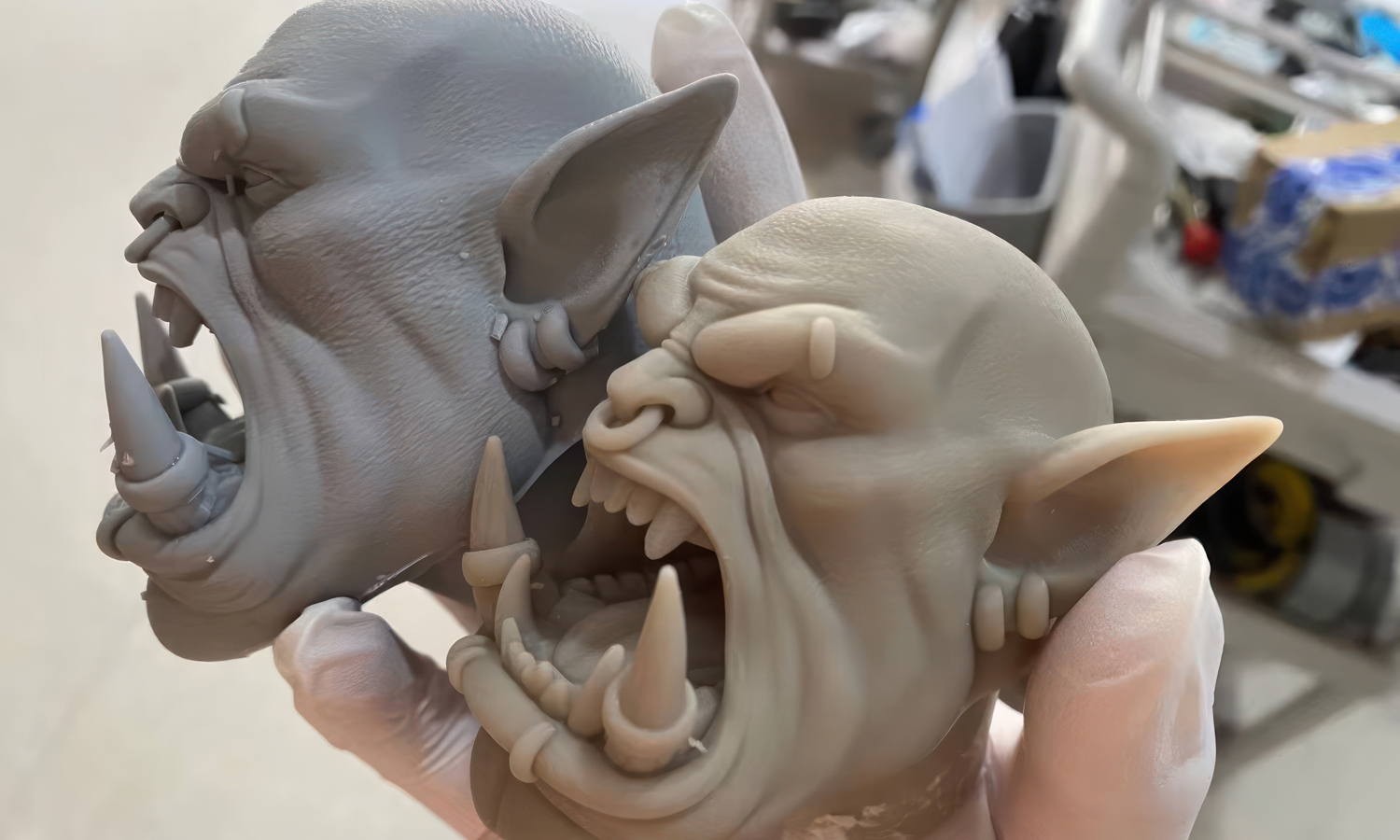

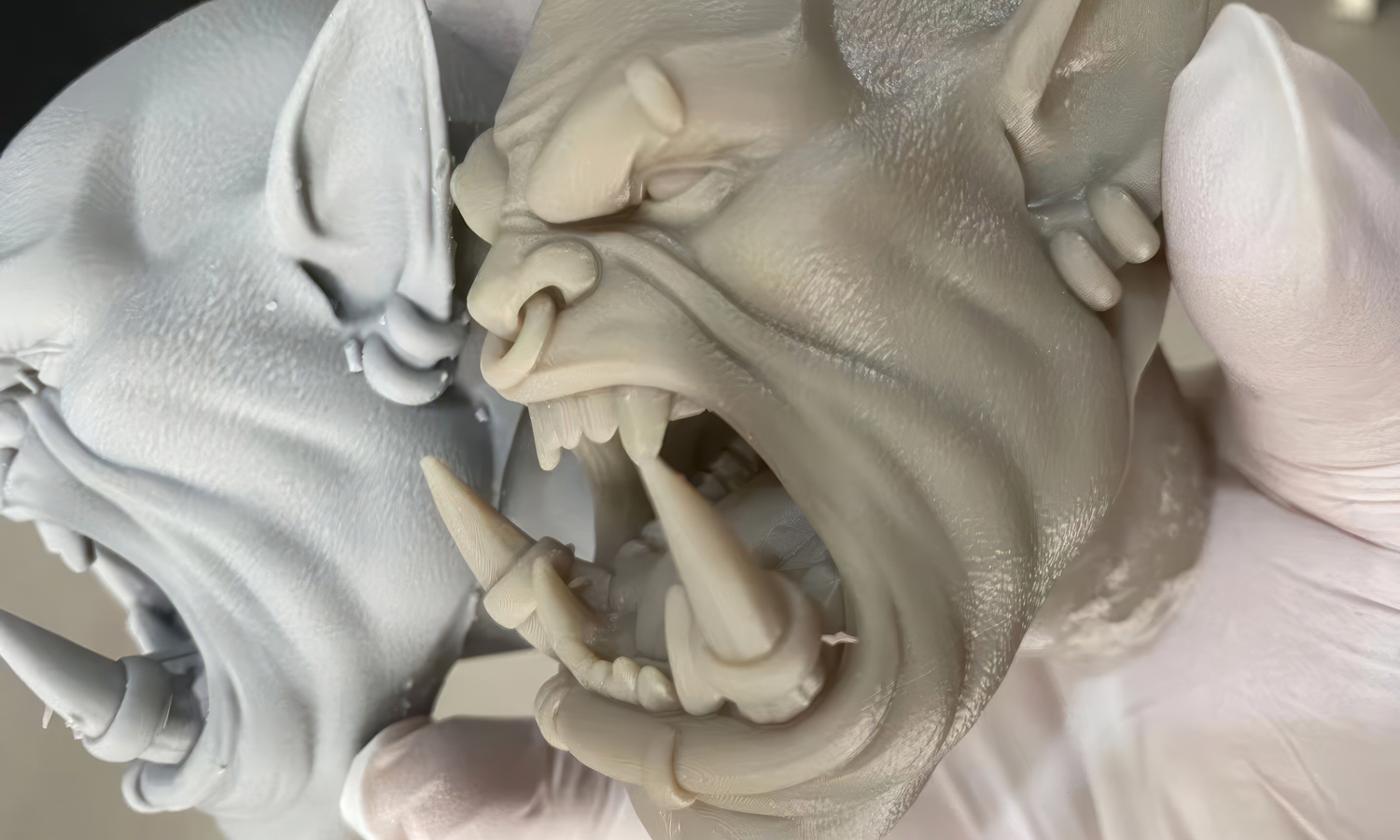

FacFox is proud to offer high-quality 3D printing services for fantastical creature sculptures, such as these DLP 3D printed fine-detail resin goblin head sculptures. These detailed goblins have pointed ears, sharp fangs, and an aggressive expression. They are printed from the same model and printed with two different colors of resin. They have delicate details and you can clearly see the furs, although there are layer lines and supporting structures that remain to be polished.

FacFox's DLP 3D printing technology is ideal for creating highly detailed and realistic creature sculptures. Our printers can produce parts with fine details and smooth surfaces, making them perfect for creating lifelike creatures.

We offer a variety of resin materials, so you can choose the best one for your project. We also offer a variety of finishing options, such as sanding, painting, and clear coating, to help you create the perfect creature sculpture.

Contact us today to learn more about our 3D printing services for fantastical creature sculptures. We can help you bring your creatures to life!

Solution

- Step 1: Model Design. The goblin head model was designed using 3D modeling software. The design included pointed ears, sharp fangs, and an aggressive expression.

- Step 2: Slicing. The 3D model was sliced into thin horizontal layers using slicing software. Each layer represented a cross-sectional area of the model.

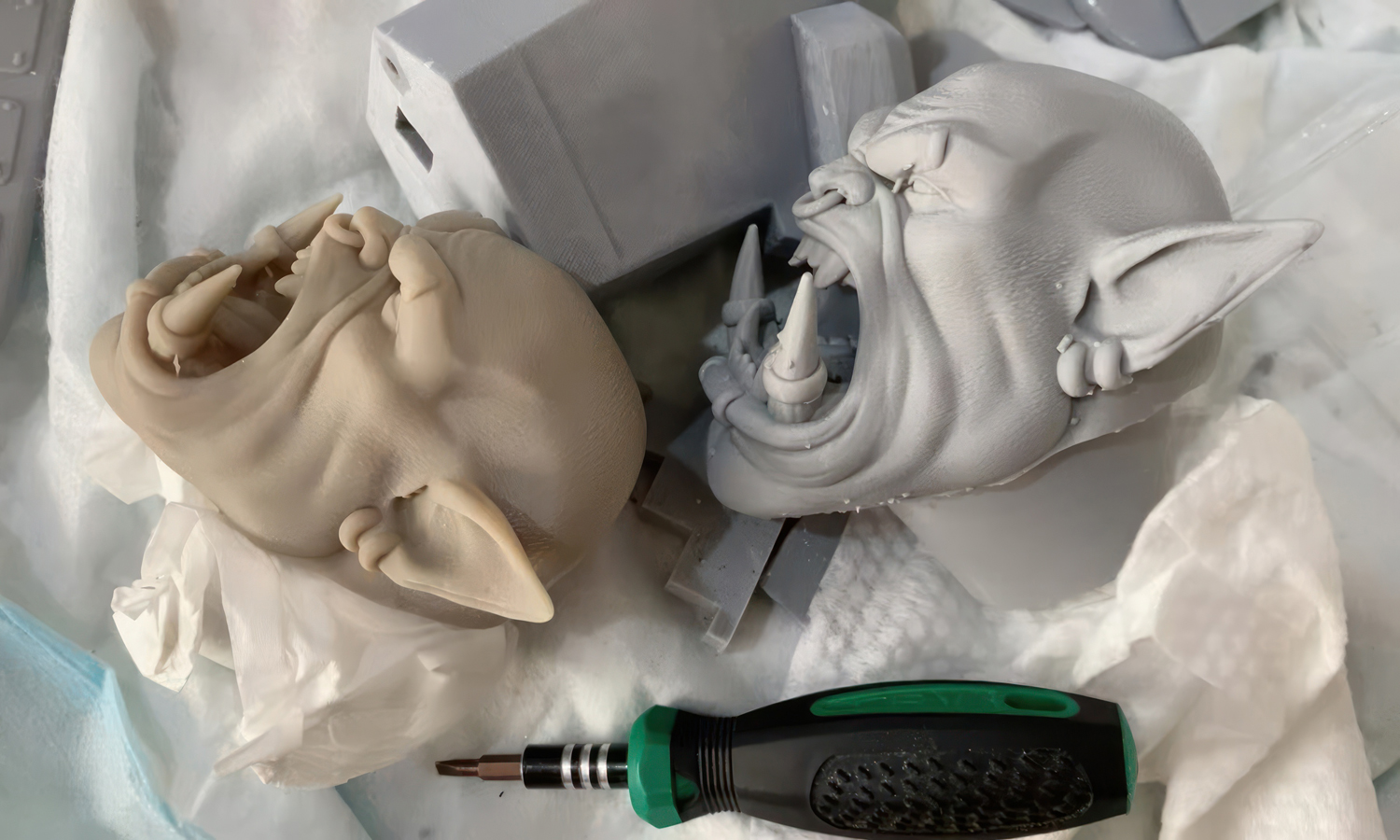

- Step 3: Preparation of the Printer. The DLP 3D printer was prepared by filling the resin vat with two different colors of photopolymer resin.

- Step 4: Layer Projection. The digital light projector projected the image of each layer onto the surface of the liquid resin. The resin was cured by the UV light, solidifying it layer by layer.

- Step 5: Building the Model. The build platform was lifted after each layer was cured, allowing fresh resin to cover the previous layer. This process was repeated until the entire goblin head sculpture was formed.

- Step 6: Post-Processing. The printed goblin head sculptures were removed from the build platform. The supporting structures were carefully detached, and the models were cleaned to remove any uncured resin.

- Step 7: Curing. The sculptures were placed in a UV curing chamber to ensure that all layers were fully hardened.

- Step 8: Polishing. The layer lines and any remaining support marks were polished to enhance the delicate details, including the visible fur textures.

- Step 9: Final Inspection. The finished goblin head sculptures were inspected for quality, ensuring that the pointed ears, sharp fangs, and aggressive expressions were accurately represented.