Gallery

About Project

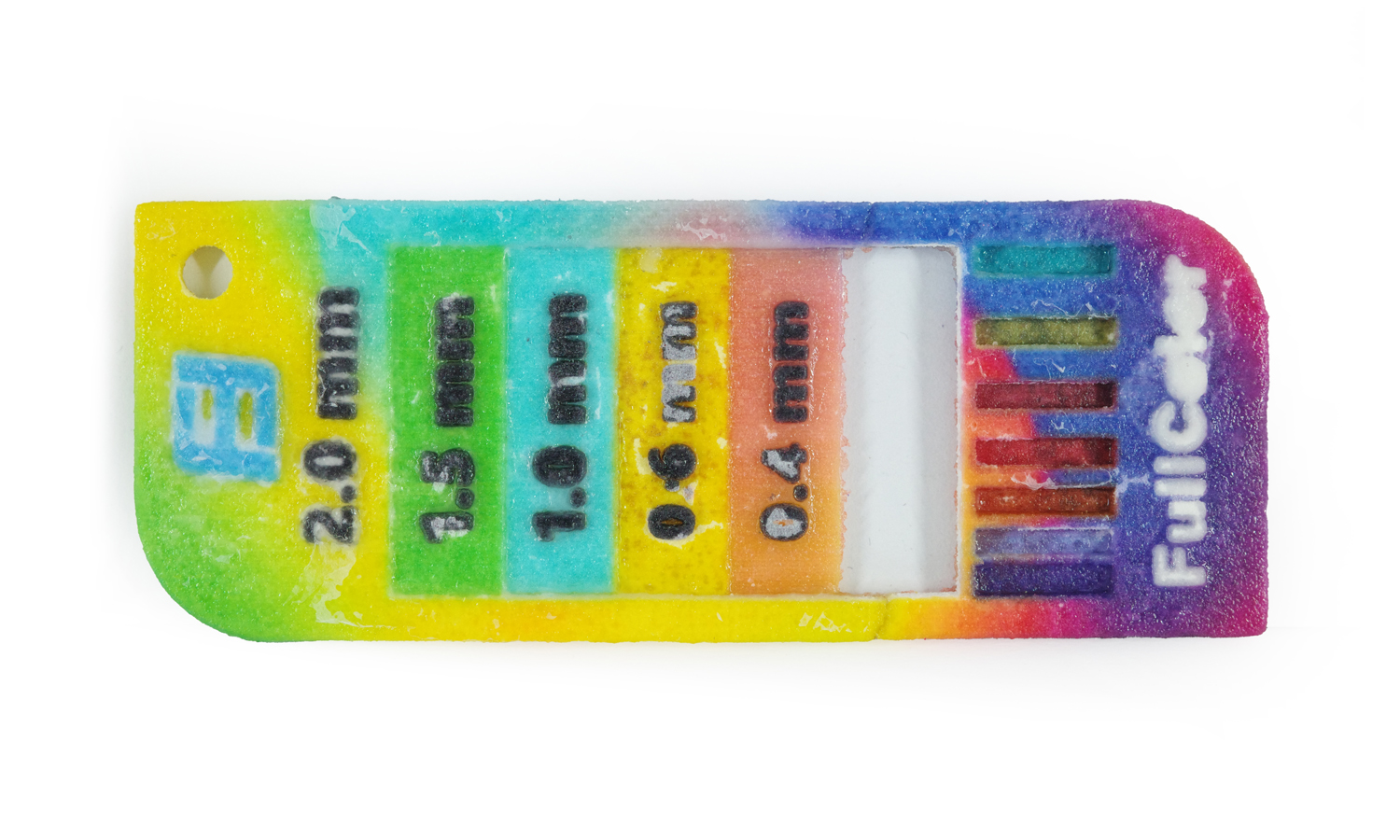

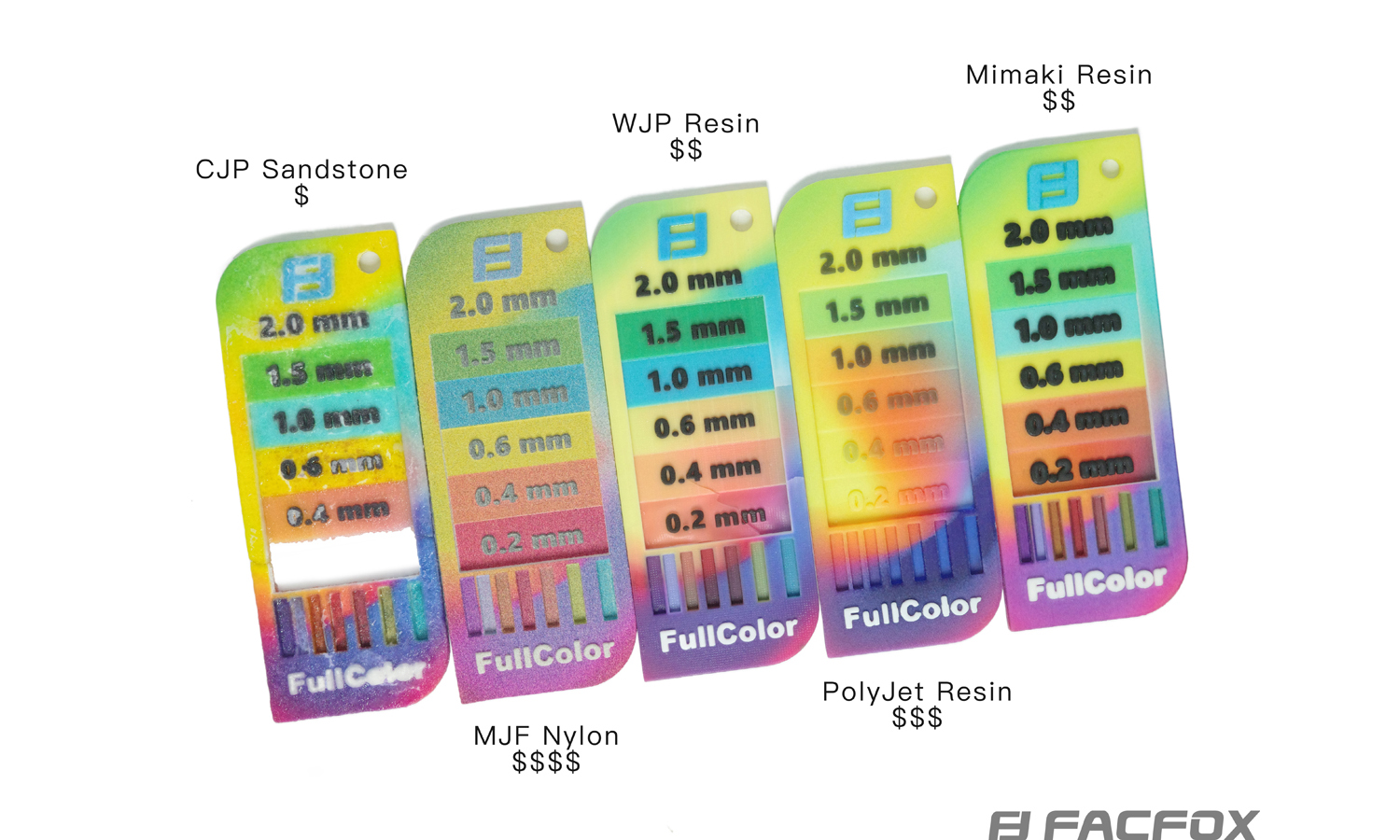

This isn’t just a wall thickness tester; it’s a vital test piece pushing the boundaries of ColorJet 3D printing. We created this vibrant, full-color tester to identify the minimum reliable wall thickness achievable with the technology. The tool features clear steps from 0.4 mm up to 2.0 mm for easy visual assessment of printed part thicknesses.

Our key findings from this specific print are insightful:

- Minimum Thickness: The 0.2 mm section proved too delicate for successful printing. As you can see, its frame broke during the process and required gluing, leaving visible glue residue and tissue fragments on the surface. This definitively shows that 0.2 mm is generally too thin for reliable ColorJet printing. Our tests suggest 0.4 mm is a more robust and safe minimum wall thickness for achieving structural integrity in your designs.

- Vibrant Hues: The colors are strikingly saturated, delivering a bold visual impact. While impressive, this high saturation can sometimes lead to slight color bleeding, especially in very thin areas.

Despite the challenges with the ultra-thin section, this print showcases ColorJet’s ability to produce complex forms with a wide color spectrum. The overall surface, outside the repaired area, is smooth, though the inherent granular texture of the process is present, adding a unique feel.

Need vibrant, full-color 3D prints, or want to understand printing limits for your specific designs? FacFox offers expert ColorJet 3D printing services. We provide honest insights into the technology’s capabilities and limitations, helping you achieve impressive results for prototypes, models, and more. Visit facfox.com to learn more and get a quote today!

Solution

- Step 1: Powder Bed.┬ĀA powder bed, typically made of gypsum-like material, is spread into a thin layer.

- Step 2: Inkjet Printing.┬ĀAn inkjet head selectively deposits a liquid binder onto the powder bed, following the desired 3D model.

- Step 3: Color Addition.┬ĀCMYK inks are added to the binder to create the desired colors.

- Step 4: Layer by Layer.┬ĀThis process is repeated layer by layer until the 3D model is complete.

- Step 5: Post-processing.┬ĀAfter printing, the part may require additional processing to improve its strength or finish, such as varnishing or dyeing.