- Precision Metal 3D Printing for Next-Generation Earbuds

- SLA 3D Printed 6-DOF Humanoid Torso Resin Prototype

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 3 workdays

Gallery

About Project

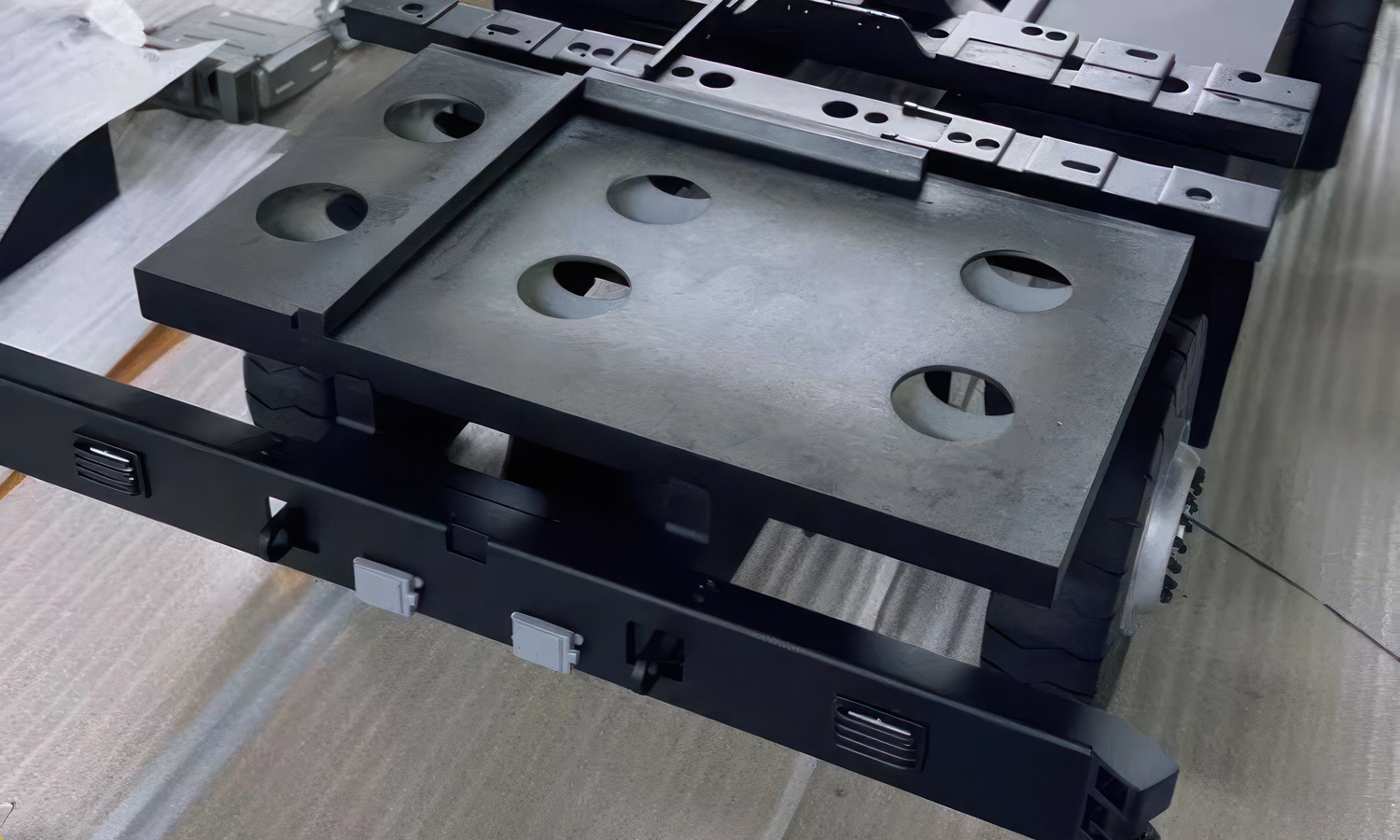

This scaled-down model of a heavy-duty tactical truck is a fantastic study in 3D-printed precision. Even at a reduced scale, the model maintains a sense of industrial weight. The cab assembly is particularly noteworthy; the pillars are straight, the window apertures are clean, and the recessed cooling vents on the front fascia show no signs of the “sagging” that often plagues complex geometries.

The chassis architecture reveals a thoughtful design-utilizing a modular frame with pre-drilled mounting points and weight-reduction cutouts. The transition from the white superstructure to the matte black structural components creates a professional contrast, highlighting the distinct mechanical sections of the vehicle. Small details, such as the integrated side-access ladder and the multi-part wheel hubs, demonstrate that this wasn’t just printed as a single block, but engineered as a complex assembly of interlocking parts. It’s a perfect example of how additive manufacturing can replicate the “bolt-together” feel of real-world heavy machinery.

For projects requiring this level of mechanical accuracy and surface quality, FacFox offers a comprehensive 3D printing service tailored for precision modeling. By utilizing professional-grade technologies like SLA for high-detail aesthetics or SLS Nylon for durable, snap-fit components, FacFox enables creators to achieve industrial results on a miniature scale. Their team can help you select from over 200 materials to ensure your scaled-down prototypes possess the exact strength and finish your design demands.

Solution

- Step 1: The entire vehicle was digitally partitioned into discrete components to maximize print resolution and ease of assembly.

- Step 2: All parts, including the bodywork, chassis frame, and tires, were printed using a consistent, high-durability resin.

- Step 3: The printed components were thoroughly washed and UV-cured to ensure maximum structural stability across all sections.

- Step 4: The support marks were meticulously sanded and polished to create the uniform surface finish seen on the cab and fenders.

- Step 5: A high-contrast color palette was applied, with the lower mechanical assemblies and tires being painted in matte black.

- Step 6: The final model was assembled by joining the painted resin components into a complete, rigid tactical vehicle.