Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 6 workdays

Gallery

About Project

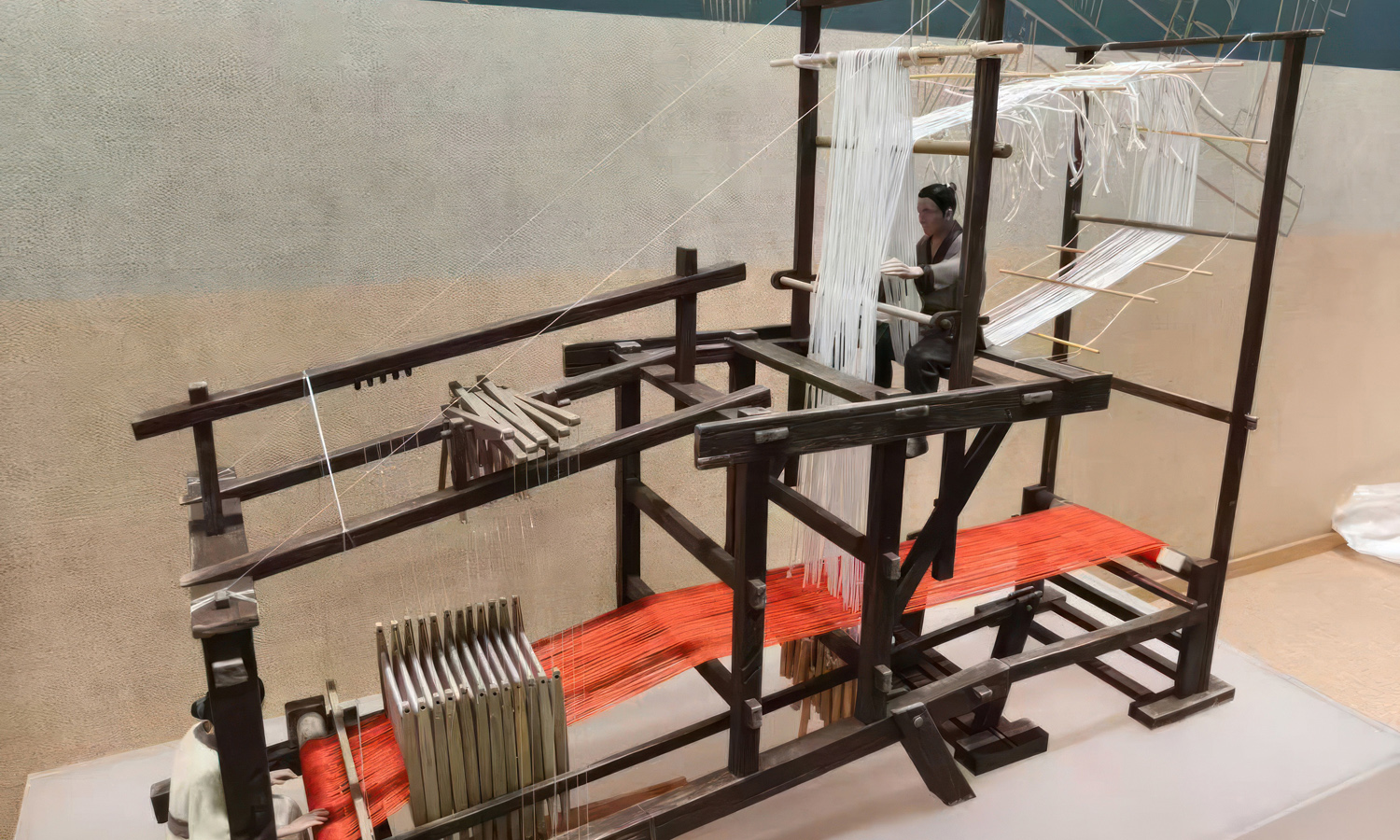

This model of a traditional weaving machine beautifully combines modern 3D printing technology with classic craftsmanship.

The entire structure, along with the miniature artisans, was 3D printed in resin, allowing for high precision and smooth surfaces. After printing, the model was carefully hand-painted to mimic the texture and tone of aged wood and fabric, giving it the authentic look of an old-fashioned loom.

From the sturdy frame to the fine rods and lifelike figures, every detail showcases the capability of resin 3D printing to reproduce both structural complexity and artistic realism. With the addition of painting and finishing, the final display piece bridges the past and present-reviving cultural heritage in a way that is both educational and visually striking.

At FacFox, we help museums, cultural institutions, and designers bring historical artifacts back to life with 3D printing + fine finishing. Whether it’s for exhibition, research, or storytelling, we transform digital designs into heritage-quality display models.

¤æē Explore what we can build for you: facfox.com

Solution

- Step 1: The weaving machine model was digitally designed based on historical references.

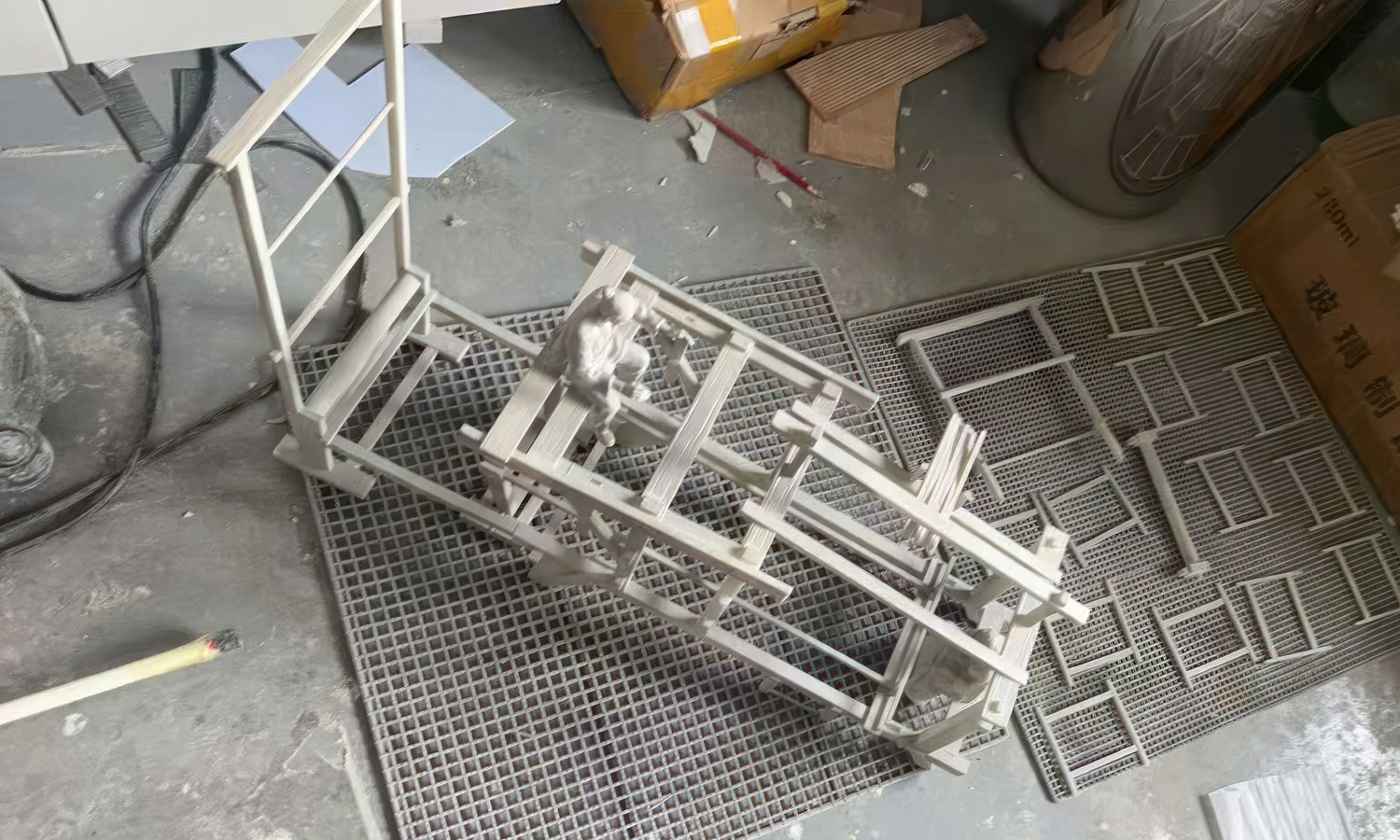

- Step 2: The components and figures were 3D printed with high-precision resin printers.

- Step 3: Supports were removed and surfaces were cleaned and cured for durability.

- Step 4: The printed parts were sanded and refined to achieve smooth surfaces.

- Step 5: Each component was hand-painted to replicate the texture of aged wood and traditional clothing.

- Step 6: The loom structure and miniature artisans were carefully assembled.

- Step 7: Final detailing and touch-ups were applied to enhance realism and authenticity.

- Step 8: The completed model was mounted and prepared for exhibition display.