Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

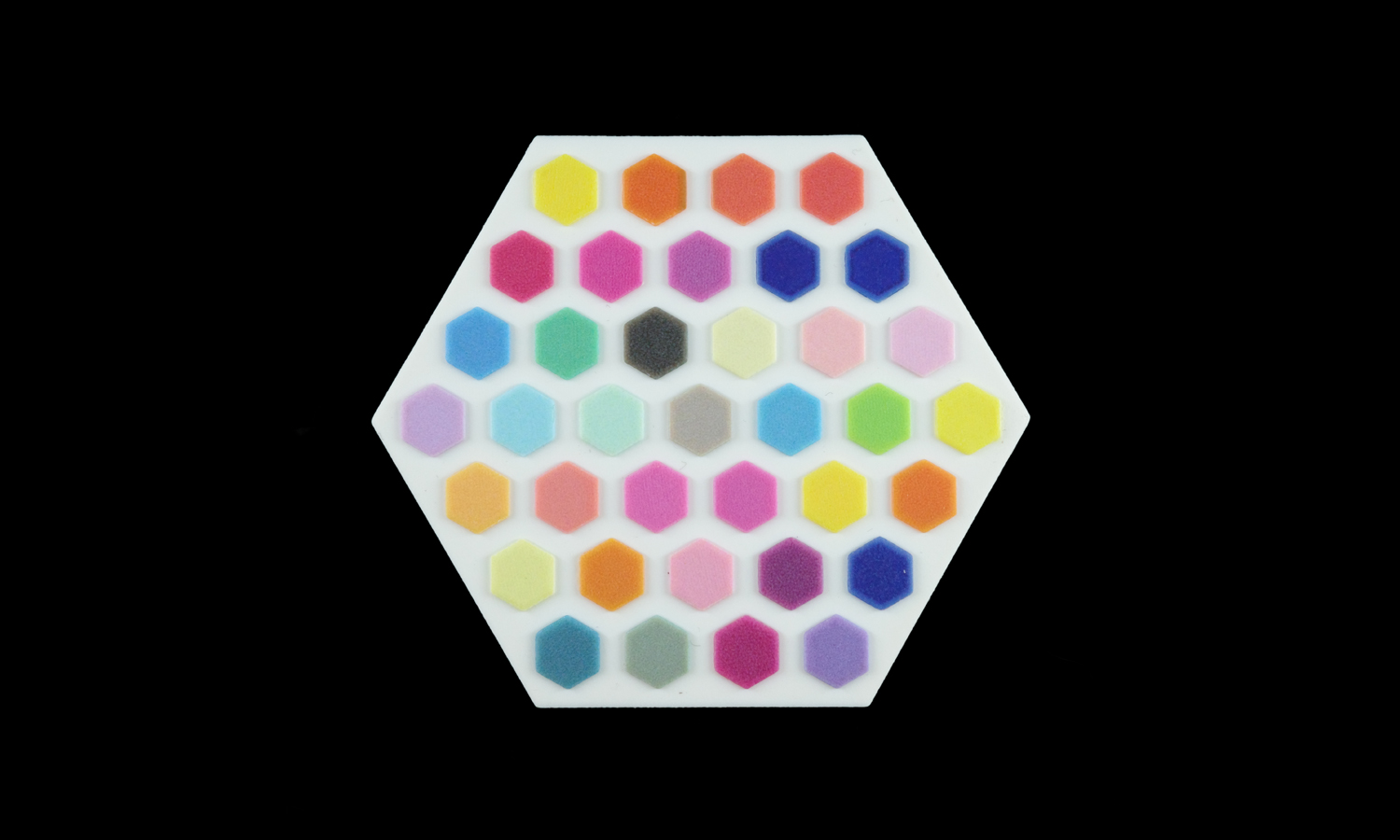

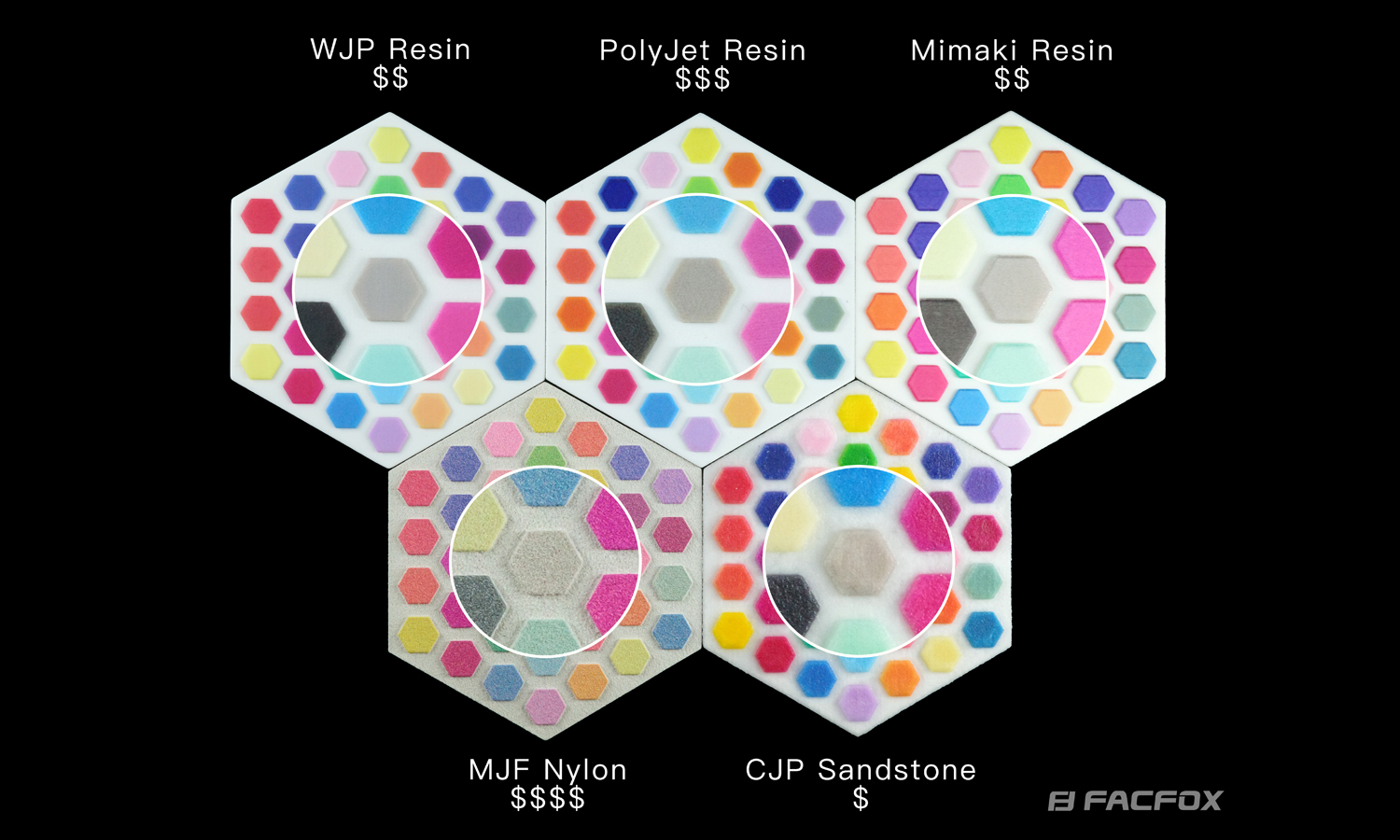

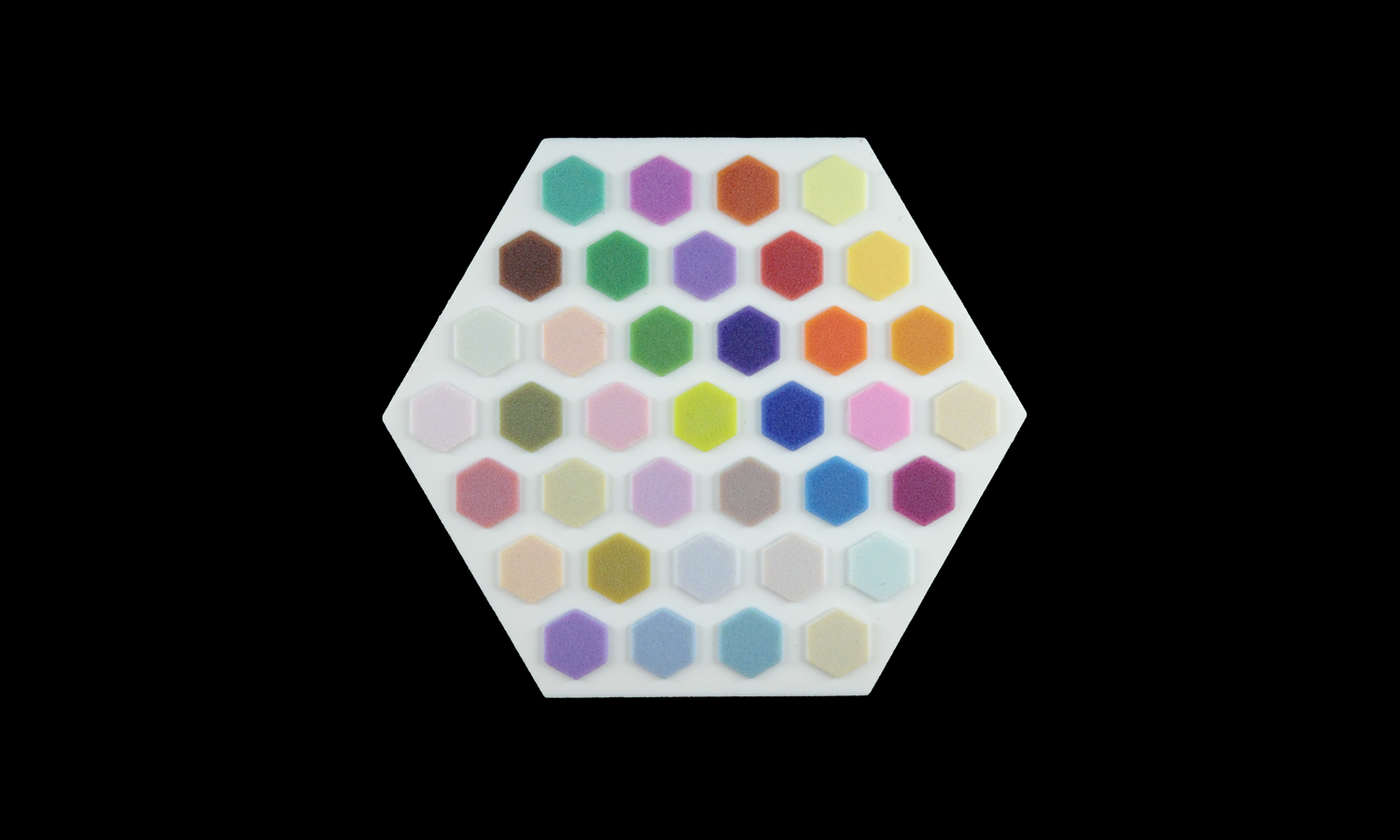

Behold this captivating array of full-color resin swatches, brought to life by PolyJet 3D printing technology! Each hexagonal tile bursts with a unique hue, showcasing the potential for intricate color reproduction.

Observing these swatches up close reveals fascinating characteristics. The overall color palette appears slightly lighter compared to what one might expect from other full-color printing methods. The boundaries between color blocks are not sharply defined, with a subtle blurring or fading of color along the edges.

The surface finish is remarkably smooth and matte. Upon closer inspection, a faint presence of mixed colors is discernible within each swatch. This su btle variegation creates an interesting visual texture that, while appearing somewhat uneven in the photograph, is actually a perfectly flat surface.

These swatches serve as a tangible testament to the capabilities of PolyJet technology in producing multi-colored parts with a smooth, consistent finish. They offer a glimpse into applications ranging from product prototypes with realistic color schemes to intricate artistic creations.

Ready to bring your vibrant ideas to life? FacFox offers professional PolyJet full-color 3D printing services. Leverage the power of multi-material and multi-color printing to create stunning prototypes, functional parts, and visually striking models with exceptional detail and a smooth, matte finish. Contact FacFox today and explore the colorful possibilities!

Solution

- Step 1: A digital 3D model was prepared using CAD software.

- Step 2: The chosen full-color resin materials were loaded into the PolyJet 3D printer.

- Step 3: Numerous tiny droplets of photopolymer resins were jetted onto a build platform.

- Step 4: Simultaneously, UV light was used to cure and solidify each layer.

- Step 5: For full-color printing, different colored resins were precisely deposited and combined during the layer-by-layer process.

- Step 6: Support structures were automatically generated and printed to support overhanging features.

- Step 7: Once the printing was complete, the build platform was removed from the printer.

- Step 8: The support materials were carefully removed from the printed part.

- Step 9: Post-processing, such as cleaning, may have been performed to achieve the final finish.