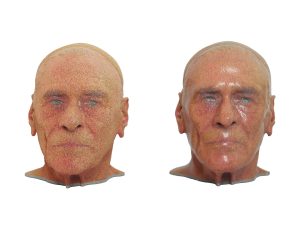

- LCD 3D Printed Resin Enclosure Pattern for Silicon Rubber Casting

- ColorJet 3D Printed Graduate Roommates’ Full-color Statue

Gallery

About Project

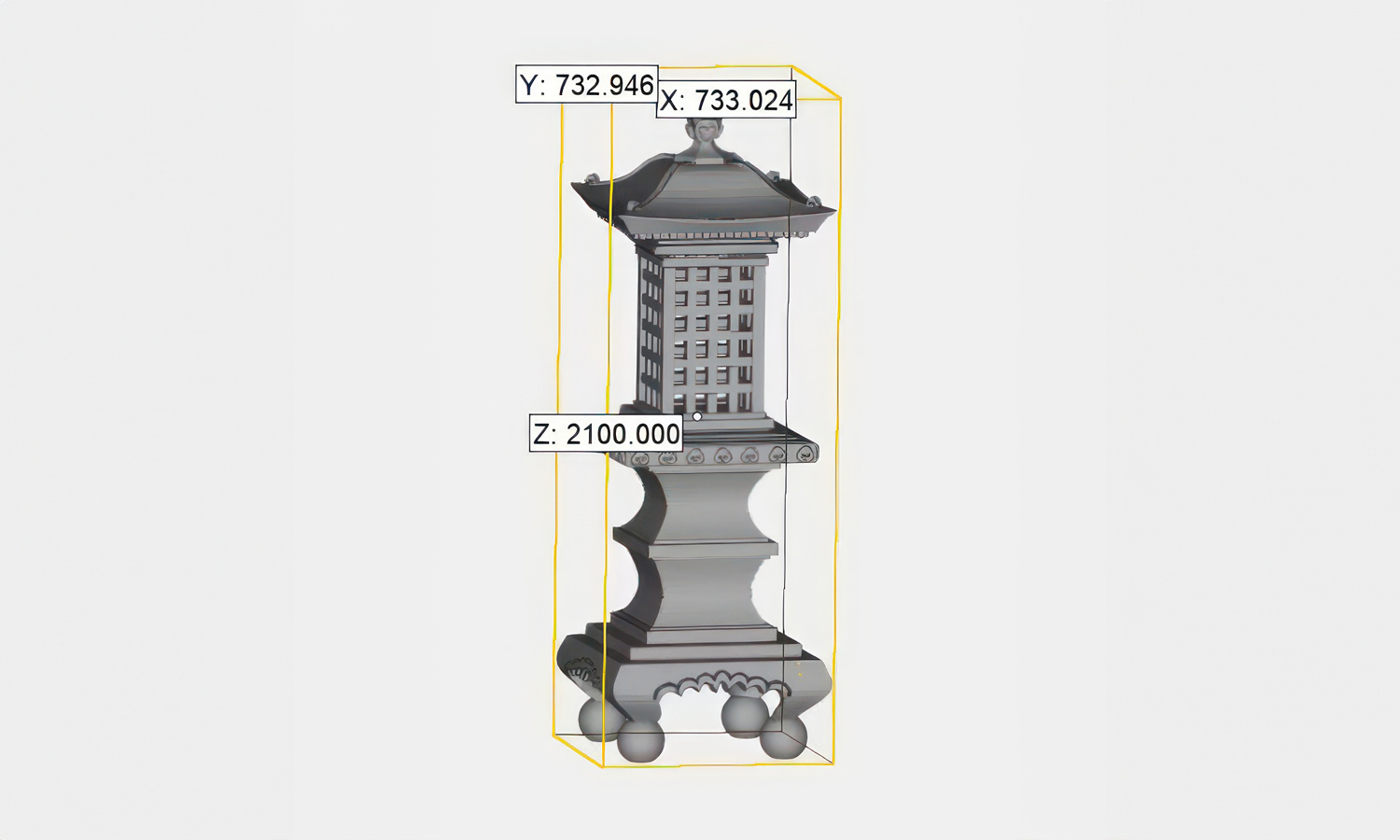

Imagine a tranquil garden bathed in the warm glow of a meticulously crafted sandstone lantern. Our BinderJet 3D printed lantern is a masterpiece of modern technology and ancient artistry, designed to elevate your outdoor space to a serene sanctuary.

Standing tall like a pavilion on a column, the lantern is a focal point that commands attention. Its intricate details, brought to life through the precision of BinderJet 3D printing, capture the essence of natural stone. The four round ball-like structures at the base anchor the lantern firmly, evoking a sense of groundedness and stability.

Surrounded by carefully chosen rocks and lush greenery, the lantern creates an enchanting atmosphere. By day, it is a sculptural marvel, a testament to the artistry of 3D printing. By night, it transforms into a beacon of light, casting mesmerizing shadows and inviting relaxation.

While the lanterns of old held tiny candles, our modern interpretation accommodates a bulb, bringing both practicality and aesthetic appeal to your garden. This fusion of tradition and innovation is a hallmark of our commitment to creating exceptional pieces.

FacFox’s BinderJet 3D printing technology is at the heart of this extraordinary lantern. We specialize in transforming digital designs into tangible realities, with a focus on precision, detail, and durability. Let us bring your garden vision to life with our custom 3D printing services. Contact us today to discuss your project and embark on a journey to create a truly unique outdoor space.

Solution

- Step 1: Design Creation. A digital model of the lantern was designed using CAD software. The design included intricate details to resemble a pavilion on a column, with a base supported by four round ball-like structures.

- Step 2: Preparation of Materials. Sandstone powder was prepared as the primary material for the BinderJet 3D printing process. A liquid binding agent was also prepared to bind the sandstone particles together.

- Step 3: Layer-by-Layer Printing. The digital model was sliced into thin layers. The 3D printer’s build platform was covered with a thin layer of sandstone powder. The printhead moved over the powder bed, selectively depositing the binding agent to form the first layer of the lantern. The powder bed was lowered, and a new layer of sandstone powder was spread over the previous layer. This process was repeated until the entire lantern was printed.

- Step 4: Curing. The printed lantern was left to cure, allowing the binding agent to fully harden and strengthen the structure.

- Step 5: Removal from Powder Bed. The cured lantern was carefully removed from the powder bed. Any loose, unbound powder was removed using compressed air.

- Step 6: Post-Processing. The lantern was inspected for any imperfections. Minor adjustments and finishing touches were made to ensure the lantern’s details were accurately represented.

- Step 7: Installation of Light Fixture. A small compartment was created within the lantern to hold a modern bulb, replacing the traditional candle used in ancient times.

- Step 8: Placement in Garden Setting. The lantern was placed in a serene garden setting. The four round ball-like structures under the base helped secure the lantern into the ground.