- SLA 3D Printed Large-format Tunnelling Shield Machine Display Model

- SLA 3D Printed Automotive Steering Joint Component Prototype

Gallery

About Project

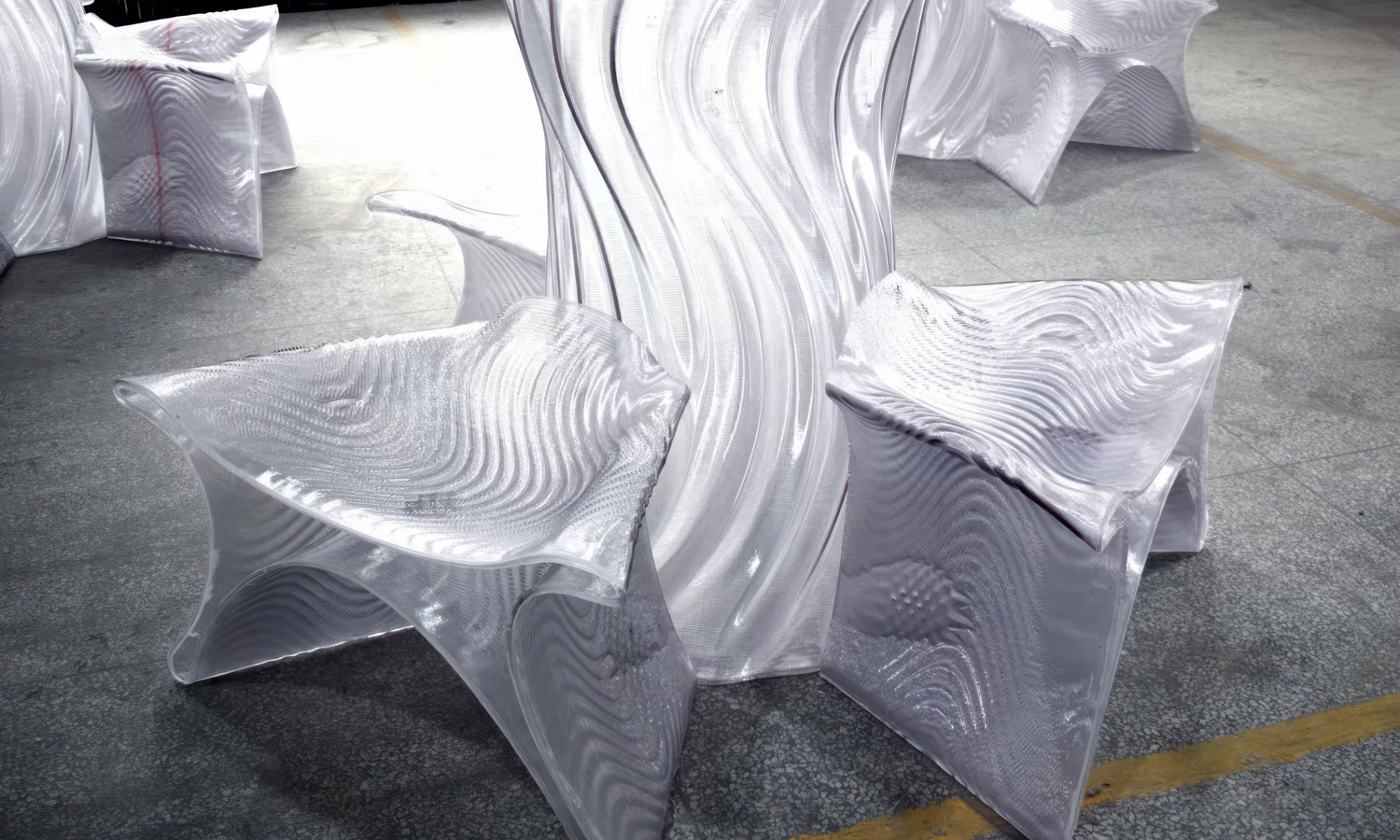

Imagine settling into a chair that feels like a piece of modern art. These captivating large-scale outdoor chairs, designed by an architecture student and brought to life through FDM 3D printing, are more than just functional furniture; they’re conversation starters and artistic focal points.

Made from a translucent material, the chairs boast a fluid, wavy design that creates an ethereal and elegant look. The modern aesthetic captures a sense of movement, reminiscent of rippling water or flowing fabric frozen in time. These chairs transcend mere utility, transforming into sculptural works of art that would perfectly complement any contemporary space. Inspired by the natural elegance of flowers, the designer has translated organic forms into a stunning statement piece.

While FacFox wasn’t responsible for printing these specific chairs, we understand the power of bringing unique design visions to life through the magic of 3D printing. Our capabilities extend to large-scale PLA furniture and sculptures, allowing you to transform your wildest ideas into reality.

So, if you’re looking to add a touch of artistry and innovation to your outdoor space, consider the possibilities of FDM 3D printed furniture. With FacFox’s 3D printing services, you can turn your design dreams into a captivating reality. Contact us today to discuss your project and explore how we can help you create something truly extraordinary.

Solution

- Step 1: Design Translation.┬ĀThe digital model is sliced into thin, horizontal layers, translating complex wavy patterns into printable instructions.

- Step 2: Material Selection.┬ĀA translucent PLA (Polylactic Acid) filament is chosen for its clarity and strength, ideal for capturing the ethereal quality of the design.

- Step 3: Printing Process.┬ĀThe 3D printer heats the PLA filament, extruding it layer by layer onto the print bed. The material cools and solidifies quickly, forming the chairŌĆÖs structure.

- Step 4: Layering Technique.┬ĀEach layer is precisely deposited, with the printerŌĆÖs nozzle following the pattern to create the fluid, wavy design that mimics rippling water or flowing fabric.

- Step 5: Post-Processing.┬ĀAfter printing, the chairs undergo a thorough cleaning to remove any support structures, followed by a polishing process to enhance their transparency and shine.