- SLA 3D Printed Dinosaur Head Resin Garage Kit

- Laser Cut and 3D Printed Hospital Architectural Scale Model

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 7 workdays

Gallery

About Project

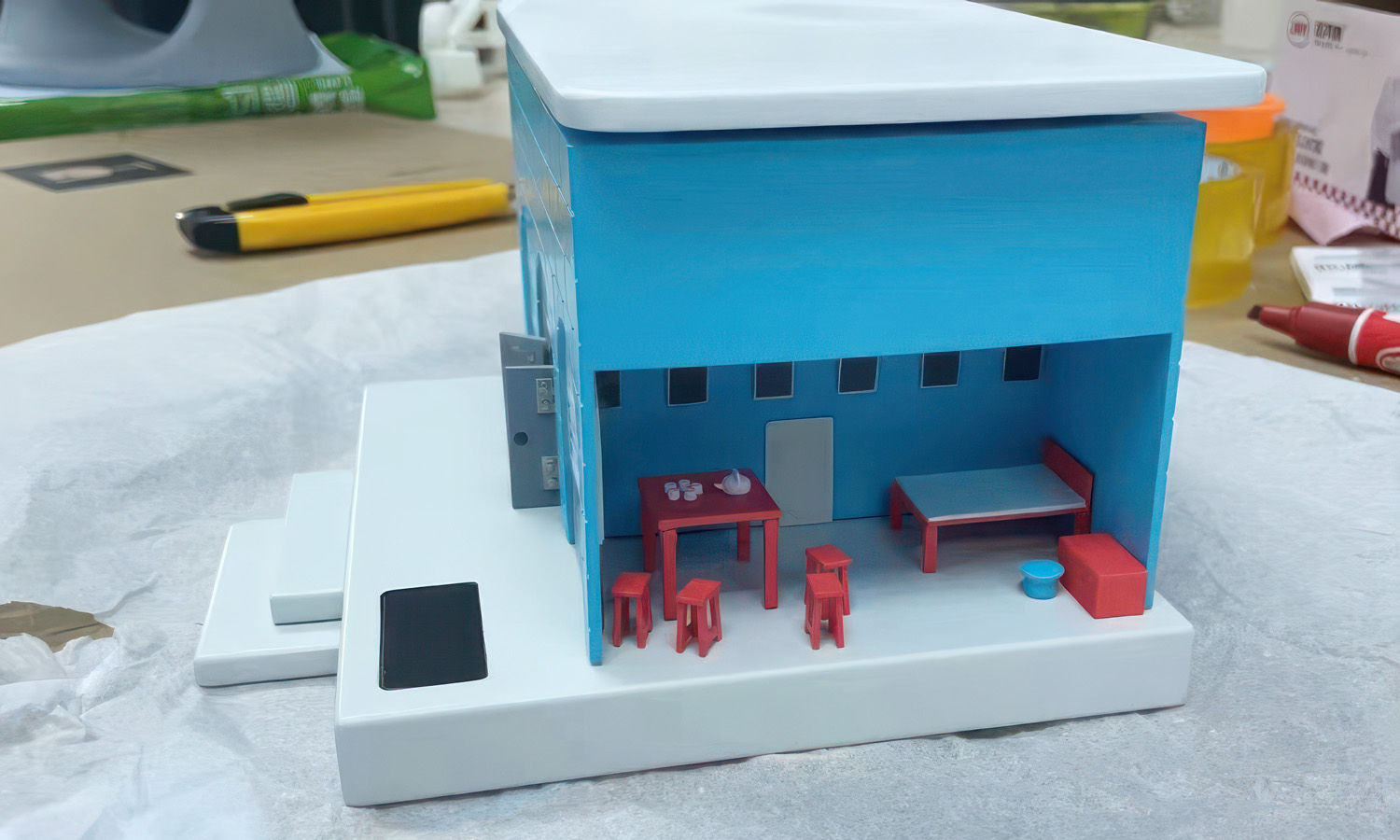

Discover the charm of classic architecture with FacFoxŌĆÖs latest creation: the SLA 3D Printed Brick House. This exquisite scale model showcases a stunning blue-painted brick facade, complemented by a crisp white flat roof, ground sill, and footsteps that invite you into its cozy embrace.

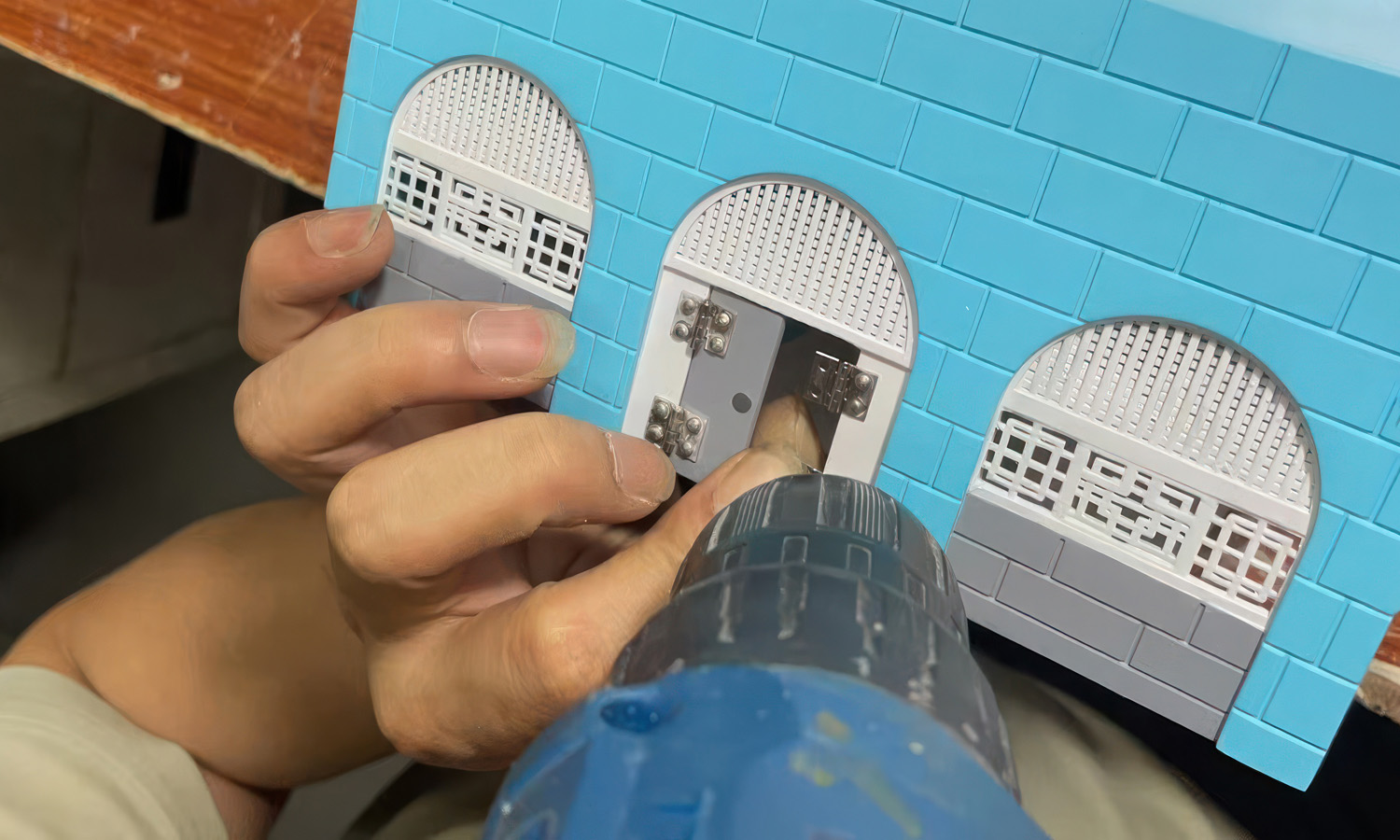

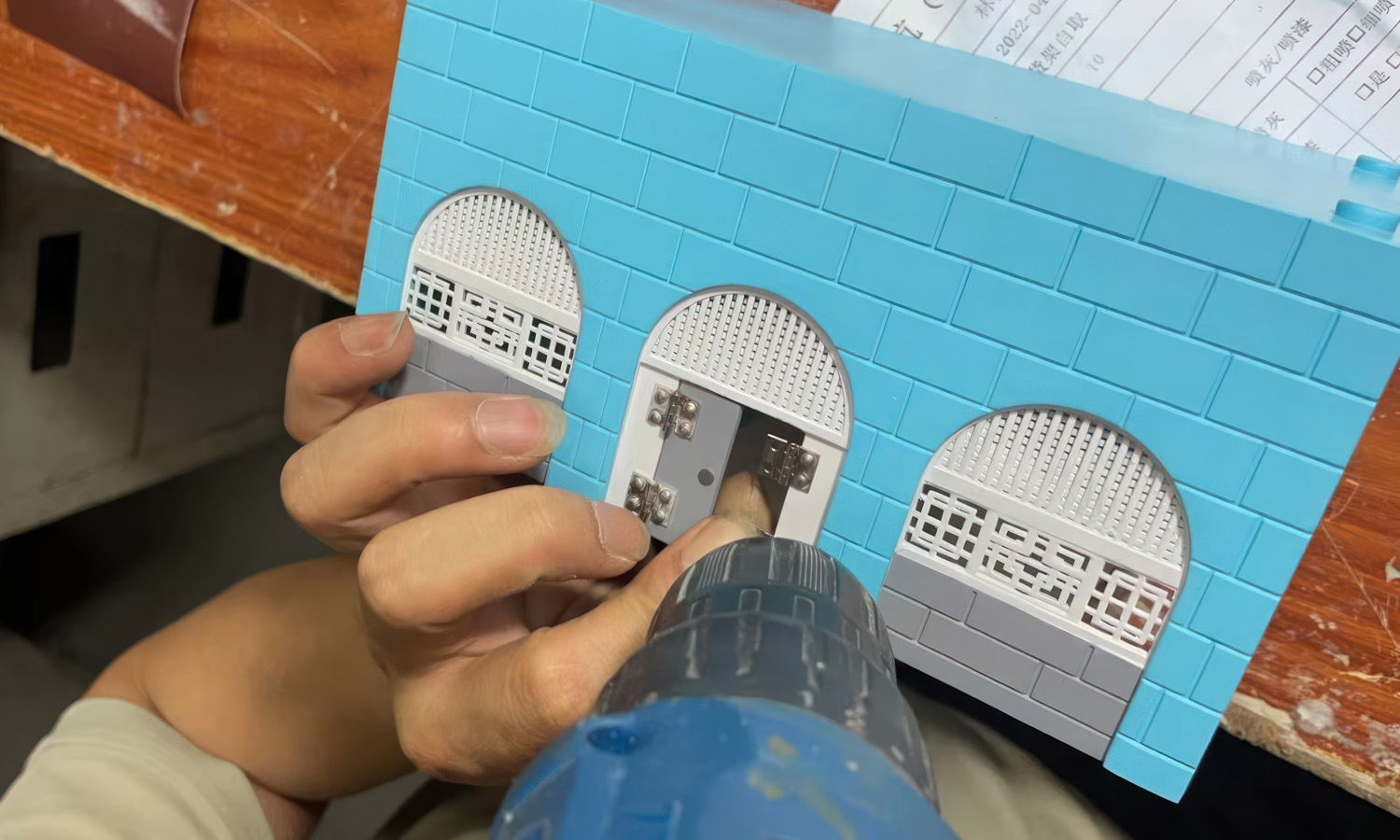

The design features two large arched windows adorned with intricate grid-like patterns, set above elegant grey brick sills that add a touch of sophistication. The centerpiece is the grey arched doorway, thoughtfully assembled with a hinge, allowing the door to swing open and welcome visitors into the warmth of the home.

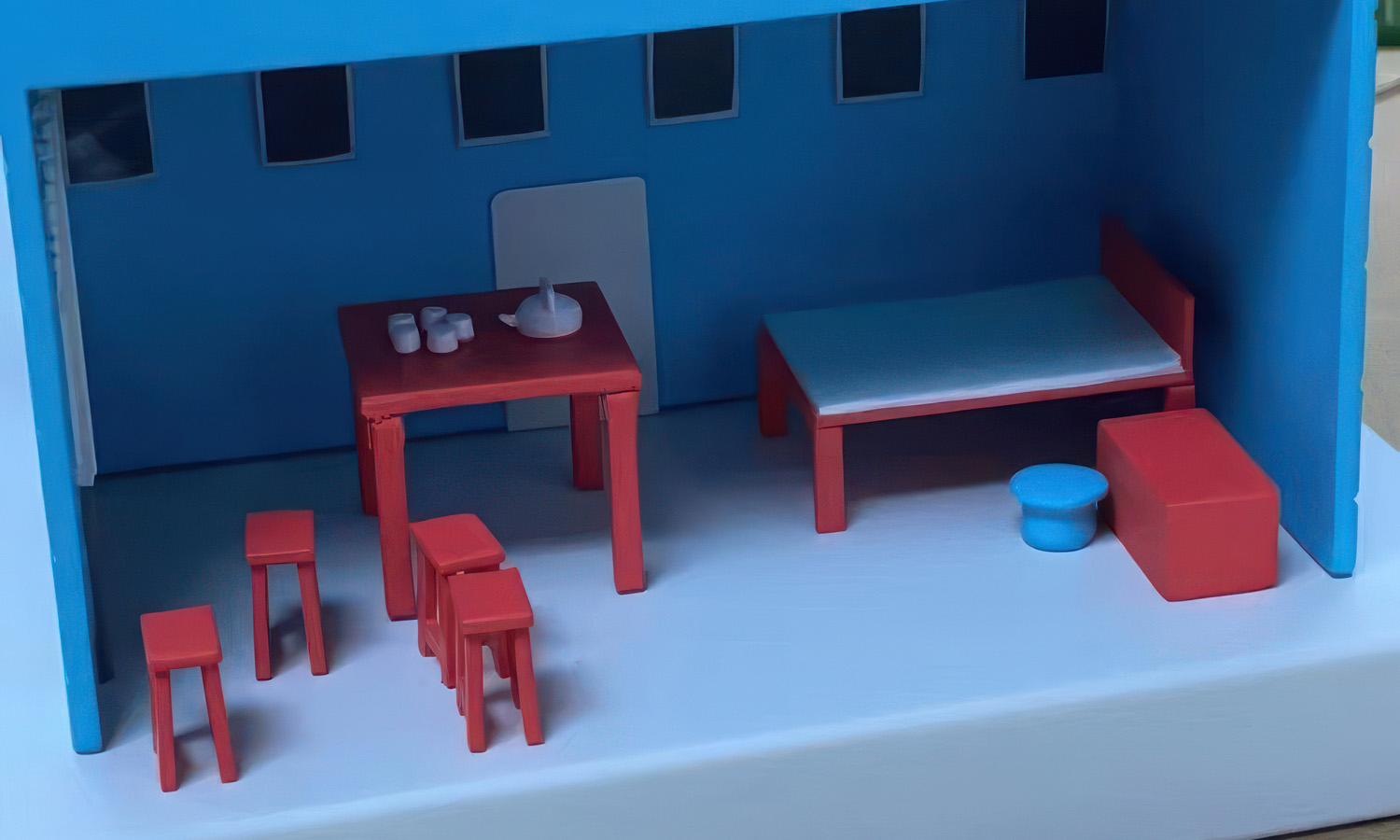

Adjacent to the main structure is a versatile overground garage, which doubles as a quaint room, perfect for creative space or storage. Inside, youŌĆÖll find charming red chairs, stools, and bed models, each crafted with precision and care.

FacFoxŌĆÖs manufacturing services bring this architectural wonder to life, offering a glimpse into the potential of 3D printing in the architectural industry. Whether for professional architects seeking a detailed representation of their designs or hobbyists looking for a unique addition to their collection, this resin scale model is a testament to the possibilities that lie within precision 3D printing.

Embrace innovation and tradition with FacFox ŌĆō where your architectural visions become tangible realities.

Solution

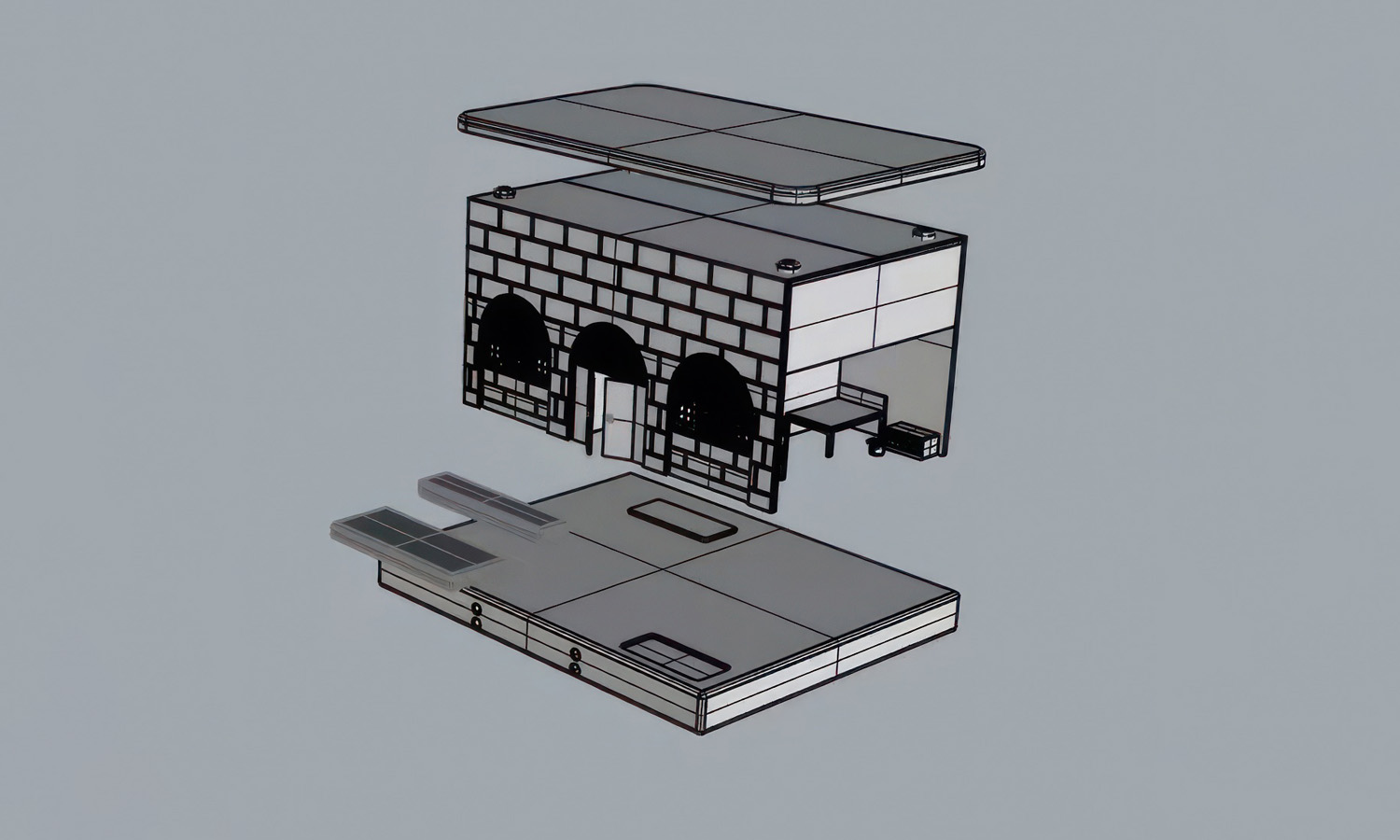

- Step 1: Design Phase.┬ĀThe model was designed using CAD software, where meticulous attention to detail was ensured for the brick houseŌĆÖs features, including the arched windows, doorway, and interior furnishings.

- Step 2: Preparation. The design file was then converted into an STL format, which was subsequently uploaded to the SLA 3D printerŌĆÖs software.

- Step 3: Support Structures.┬ĀSupports were generated and attached to the model where necessary, ensuring stability and maintaining the integrity of overhanging features and fine details.

- Step 4: Printing Process.┬ĀThe build platform was lowered into a tank filled with liquid resin. A UV laser was employed to cure the resin, solidifying the first layer of the model.

- Step 5: Layer Formation.┬ĀThe build platform was incrementally raised, and the laser continued to cure the resin layer by layer, allowing the brick house model to take shape.

- Step 6: Post-Processing.┬ĀOnce the printing was completed, the model was carefully removed from the build platform. The supports were then removed, and the model was washed in isopropyl alcohol to eliminate any uncured resin.

- Step 7: Curing. The model was placed in a UV curing chamber to further harden the resin, ensuring durability and the correct final properties of the material.

- Step 8: Assembly. The arched door, which was printed separately with a hinge, was attached to the main structure, allowing it to open and close.

- Step 9: Painting. The brick house model was hand-painted in blue, with the roof, ground sill, footsteps, and window sills painted white, and the door and window sills in grey, as per the design specifications.

- Step 10: Finishing Touches. Finally, miniature furniture models, including red chairs, stools, and a bed, were placed inside the garage to complete the scene.