Laser Cut and 3D Printed Hospital Architectural Scale Model

- SLA 3D Printed Brick Houses with Arched Doorway Resin Scale Model

- ColorJet 3D Printed Sandstone Jeep Model with Steerable Wheels

Posted on 2024-02-20 in Architecture ┬Ę Õ╗║ńŁæ

Process 3D Print, Support Removal, Post Curing, Laser Cutting, Paint, Glueing

Material Resin, Other

Quantity 1 pcs

Price Range $1,000-5,000

Lead Time 23 workdays

Material Resin, Other

Quantity 1 pcs

Price Range $1,000-5,000

Lead Time 23 workdays

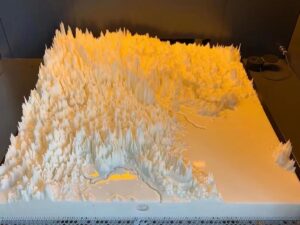

Gallery

About Project

Feast your eyes on this stunning architectural scale model of a hospital complex! The intricate details will leave you in awe.

- Patient Rooms: Peer inside and see miniature hospital beds, hinting at the spaces where patients find comfort and care.

- Specialized Areas: Discover rooms filled with cutting-edge medical equipment, showcasing the hospital's advanced treatment capabilities.

- Crystal-Clear View: Transparent walls grant an unobstructed view into every corner of this architectural marvel.

- Lush Surroundings: A touch of green represents a tranquil outdoor garden, while details like a sewage treatment station and oxygen generating room add realism.

How did we achieve this level of detail?

- Laser-Cut Precision: MDF and acrylic boards were meticulously cut to create the hospital's structure.

- 3D Printed Wonders: Resin 3D printing brought life to the tiniest elements ŌĆō beds, desks, medical equipment, and even lifelike figures!

Need A Complex Architectural Model? Trust FacFox! Our mastery of laser cutting and 3D printing allows us to tackle the most intricate projects. We bring architectural visions to life with breathtaking precision. Contact FacFox and let us transform your blueprint into a stunning scale model!

Solution

- Step 1: Design and Planning. The hospital modelŌĆÖs design was meticulously planned, considering the layout of patient rooms, specialized treatment areas, and outdoor spaces. Detailed blueprints were created, specifying the dimensions and features of each room.

- Step 2: Material Selection. First, MDF (Medium-Density Fiberboard) sheets were selected for the base structure. These boards provide stability and a smooth surface for the model. The MDF boards were cut using a laser cutter to create the overall shape of the hospital building. Transparent acrylic sheets were chosen for the walls. Their transparency allows viewers to see inside the rooms. The acrylic panels were also laser-cut to match the dimensions of the rooms and corridors.

- Step 3: 3D Printing Process. The beds, desks, cupboards, computers, medical equipment, and dummies were 3D printed using resin-based 3D printers. Resin printing allows for intricate details and precise scaling, ensuring realism in the model.

- Step 4: Integration and Finishing: The laser-cut MDF base and acrylic walls were assembled, securing the transparent panels in place. The 3D-printed components were carefully glued into their respective positions. LED lights were also assembled to light up every ward. Final touches, such as painting and adding tiny details (like potted plants or signage), were done to enhance realism.

- Step 5: Quality Check and Presentation: The completed hospital model underwent a thorough quality check to ensure accuracy and visual appeal. It was then presented to stakeholders, architects, or project teams for review and feedback.