- SLS 3D Printed TPU Squeezable Hollowed Flower with Raw Finishing

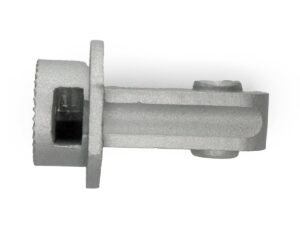

- SLS 3D Printed PP Spring Raw Finishing

Gallery

About Project

Introducing the remarkable SLS 3D Printed PP Spring Dyed Black! This captivating piece combines aesthetics with functionality, showcasing the endless possibilities of 3D printing. Crafted using state-of-the-art SLS (Selective Laser Sintering) technology, the spring boasts a unique grainy surface texture that adds a touch of distinctiveness to its overall appearance.

One standout feature of this spring is its intriguing color. Through a meticulously controlled soaking process, it has been successfully transformed into a striking black hue. This dyeing method not only enhances the visual appeal of the spring but also adds to its durability and resistance to wear and tear.

But what sets this 3D printed spring apart is its exceptional elasticity. When you gently pinch the two ends of the spring, it responds with remarkable flexibility, stretching out effortlessly and promptly springing back into its original shape. The precise engineering and meticulous design of this PP spring allow it to withstand repeated use and maintain its functional integrity.

This innovative creation serves as a testament to the vast potential of 3D printing technology. With the ability to fabricate complex geometries and intricate designs, SLS 3D printing offers unparalleled versatility in manufacturing tailor-made components. The grainy texture and mesmerizing black dye of this spring exemplify the level of customization and attention to detail achievable through this cutting-edge additive manufacturing process.

If you’re inspired by this remarkable 3D printed PP spring and wish to explore similar possibilities or bring your own unique designs to life, look no further than FacFox’s SLS PP printing service. With their expertise in additive manufacturing and a commitment to delivering high-quality results, FacFox stands out as a trusted partner for all your 3D printing needs. Whether you’re a designer, engineer, or hobbyist, their advanced SLS printing technology coupled with a wide range of materials ensures that your projects are realized with precision, accuracy, and unparalleled creativity.

Unlock the potential of 3D printing with FacFox and experience the seamless union of artistry and functionality in your own projects. Contact them today via info@facfox.com to embark on your transformative journey into the world of SLS 3D printing.

Solution

- Step 1: The PP powder was prepared and placed in the SLS 3D printing machine, where it awaited processing.

- Step 2: The SLS 3D printer was set up, calibrated, and the necessary parameters for printing the PP spring were configured.

- Step 3: Layer by layer, a laser was utilized to selectively fuse the PP powder particles together, following the precise design specifications.

- Step 4: The 3D printing machine continued building the spring, gradually forming its intricate geometry and smooth surface.

- Step 5: Once the spring finished printing, it was carefully removed from the printing chamber. No supports need to be removed with this technology and material.

- Step 6: Post-processing began with the spring being cleaned to remove any excess powder residue from the printing process.

- Step 7: To achieve the desired black color, the spring was soaked in a specially formulated dye solution.

- Step 8: The soaking process allowed the dye to permeate and impregnate the PP material, resulting in a consistent black coloration throughout the spring.

- Step 9: The final step involved inspecting the spring for quality assurance, ensuring its elasticity, surface texture, and overall integrity met the desired standards.