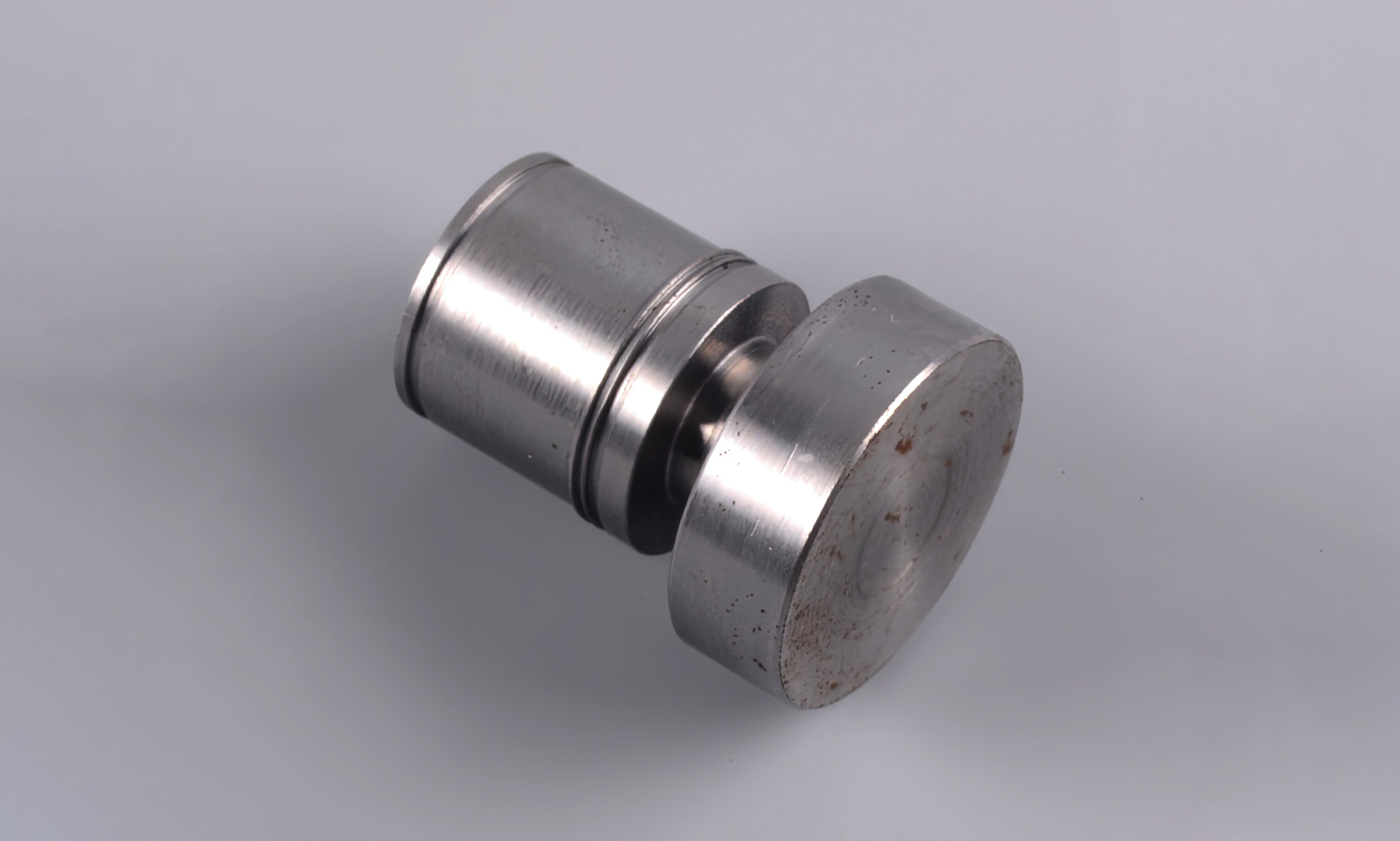

- CNC Milled Threaded Chain Pin Aluminum Slider Pin Shaft Kit

- CNC Milled Aluminum 6061 Bracket Mounting L-shaped

Gallery

About Project

Are you looking for a unique and stylish door knob that will make your home stand out? Look no further than FacFox! Our CNC services can help you create your own custom door knobs and other parts.

Our team of experts will work with you to create the perfect part for your project. We use only the highest quality materials to ensure that your parts are durable and long-lasting.

Aluminum 6061 is a popular material for CNC machining because of its excellent properties. It has good corrosion resistance, mechanical properties, formability, weldability, and machinability. It is generally suitable for medium to high strength requirements and has good toughness.

At FacFox, we pride ourselves on our commitment to quality and customer satisfaction. We have received excellent reviews from our customers, who appreciate our attention to detail and our dedication to providing the best possible service.

Our CNC Milled Button Stop Door Knob made with Aluminum 6061 is the perfect addition to any home. The sleek and modern design will complement any decor style, while the durable construction ensures that it will last for years to come.

Contact us today via info@facfox.com to learn more about our CNC services and how we can help you create the perfect part for your project.

Solution

- Step 1: The CAD model was examined and transformed into a CNC-compatible format with the software AutoCAD.

- Step 2: A most suitable type of CNC machine was chosen according to the complexity of the product design and the cost of the workpiece.

- Step 3: Certain operations were configured and the G-codes were input on the machine. The workpiece was mounted on the machine as well.

- Step 4: The workpiece got shaped and the holes were drilled automatically. It would be inspected during and after the machining process for quality assurance.

- Step 5: The part was degreased and manually cleaned, and then placed into a preheated chrome plating vat for minutes.