- PolyJet vs Binder Jetting 3D Printed Full-color Head Sculpture of Noblewoman

- PolyJet vs Binder Jetting 3D Printed Leonardo DiCaprio Full-color Head Sculpture

Gallery

About Project

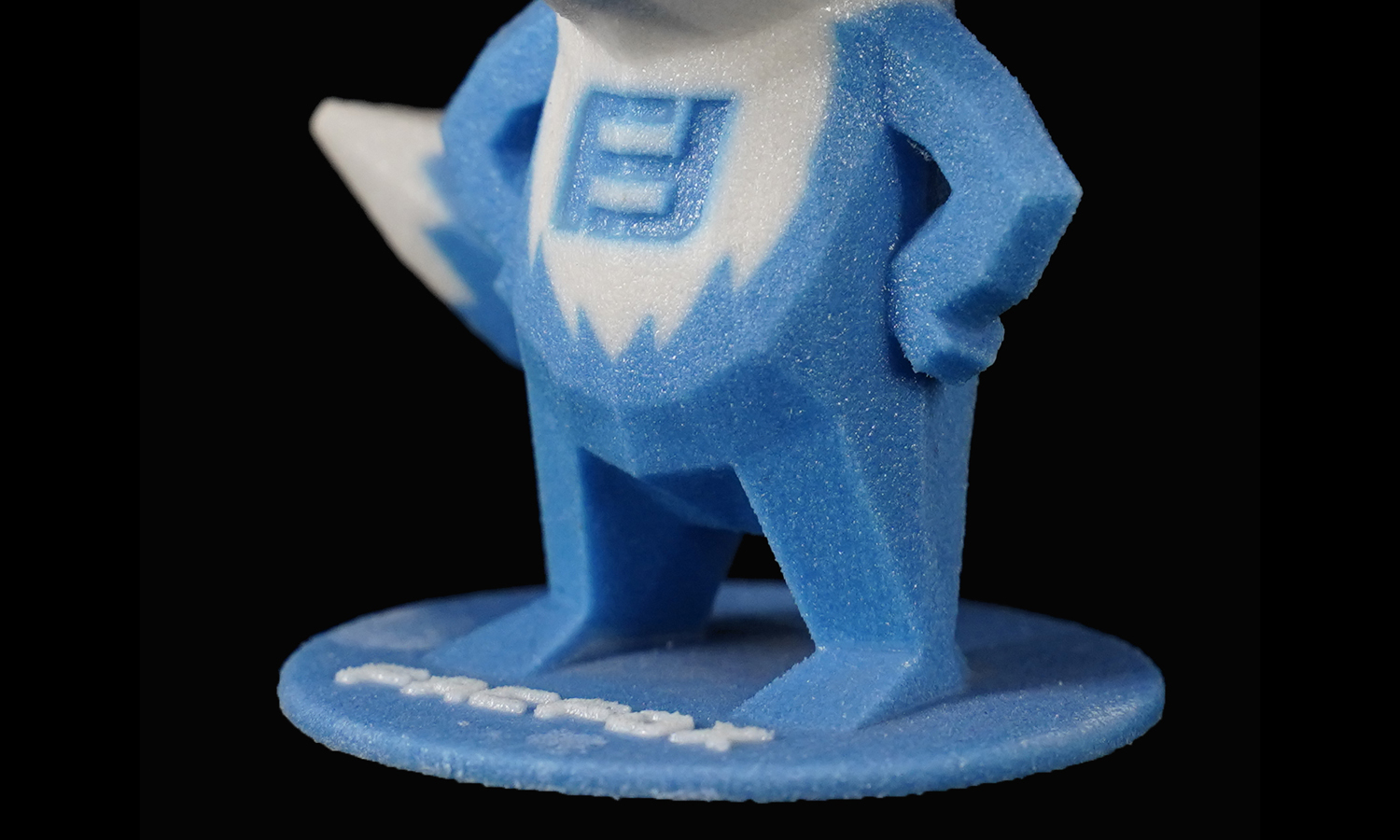

Have you ever wondered how to create a stunning full-color 3D printed statue that looks like it came straight out of a painting? Well, meet Henry, the adorable fox mascot of FacFox, a leading 3D printing service provider. Henry is not just any ordinary fox; he is a masterpiece of Binder Jetting 3D printing technology.

Binder Jetting is a 3D printing process that uses a liquid binder to selectively join layers of powdered material. The powdered material can be ceramic-based (such as glass or gypsum) or metal-based (such as stainless steel). The binder can also be colored with inkjet technology to create vibrant and realistic colors.

Henry is made of sandstone-like material that is inkjet colored and glued together during the 3D printing process. He has a coarse surface texture but vivid colors that make him stand out from other 3D printed statues.

Henry is one of the many examples of how FacFox can help you create amazing full-color 3D printed models with Binder Jetting technology. Whether you need an architectural model, a packaging prototype, a toy, or a figurine, FacFox can deliver high-quality and affordable Binder Jetting 3D prints for your needs.

If you want to learn more about Binder Jetting 3D printing or order your own Henry statue, visit FacFoxŌĆÖs website today and get ready to be amazed by their full-color printing service.

Solution

- Step 1: As the default layer thickness is 0.1mm and sandstone prints have medium tolerance, the thickness of all the modeling details was examined to ensure they can all be printed out.

- Step 2: A rolling batch left a uniform layer of sandstone-like powder. From there two printing heads passed over the batch, coloring and adhering to the object at the same time. The batch of powder then made another pass, until the object was completed.

- Step 3: After printing, the statue was then coated with cyanoacrylate (super glue) or a different infiltrant to improve part strength and enhance the vibrancy of the colors. A secondary epoxy layer could then also be added to further improve strength and color appearance.

- Step 4: Smoothened the surface with electrolytic polishing technique and coated them into silver and with electroplating.