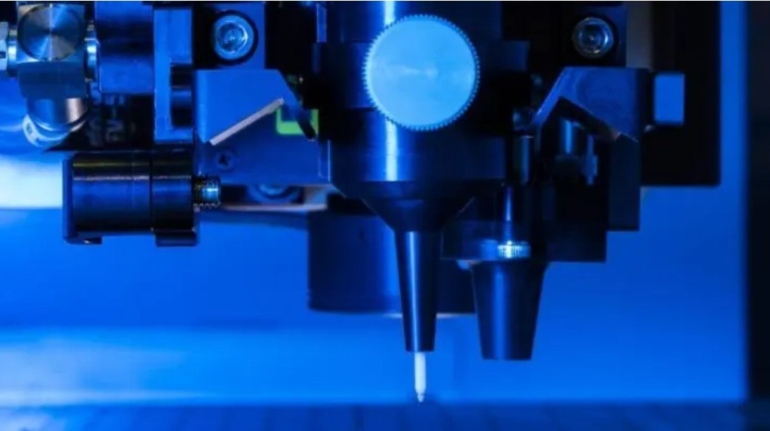

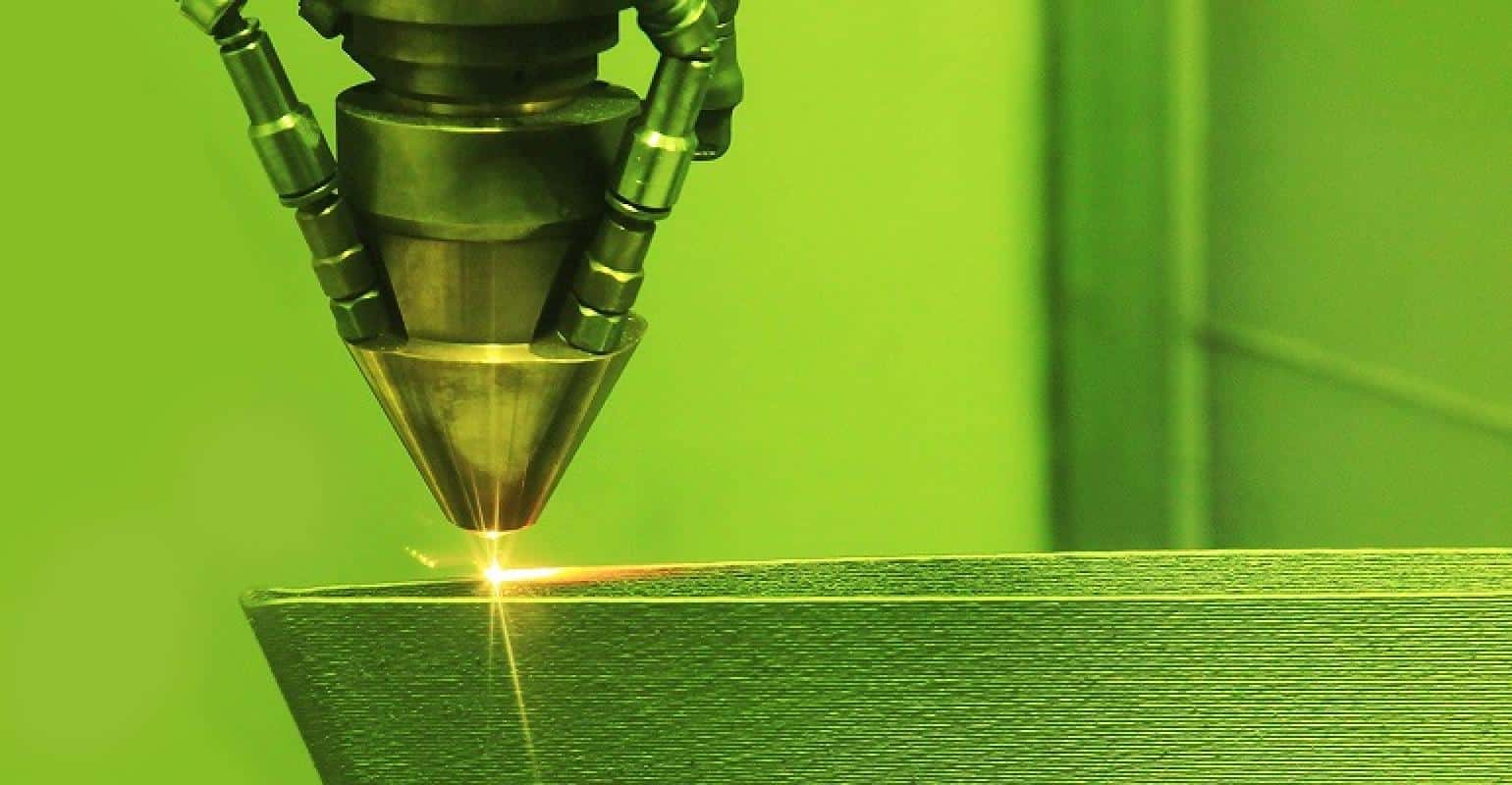

Rochester Institute of Technology Installs ElemX Metal 3D Printer

The Rochester Institute of Technology (RIT) recently purchased and installed a Xerox ElemX 3D printer from Xerox Elem Additive Solutions at their AMPrint Center in Henrietta, NY. RIT will utilize the printer in their collaborations with manufacturers for research and product development as they focus on next-generation metal 3D printing technologies.