Araqev, a Purdue University-related company, has commercialized a quality-control software that could benefit the aerospace, automotive, consumer products, medical devices, national defense, and other sectors that use additive manufacturing technology.

Araqev’s quality-control software enables end-users to print products in only a few design iterations, resulting in less scrap material and machining time, lessening frustrations, and improving the overall quality of the final printed products. “We estimate that the quality-control issue with additive manufacturing can lead to nearly $2 billion in global losses annually based on a model for the production costs of metal additive manufacturing systems that was developed by Baumers, Dickens, Tuck and Hague in their 2016 paper published in the peer-reviewed journal Technological Forecasting and Social Change,” said Arman Sabbaghi, associate professor at Purdue’s Department of Statistics in the College of Science, and Araqev’s CEO and president.

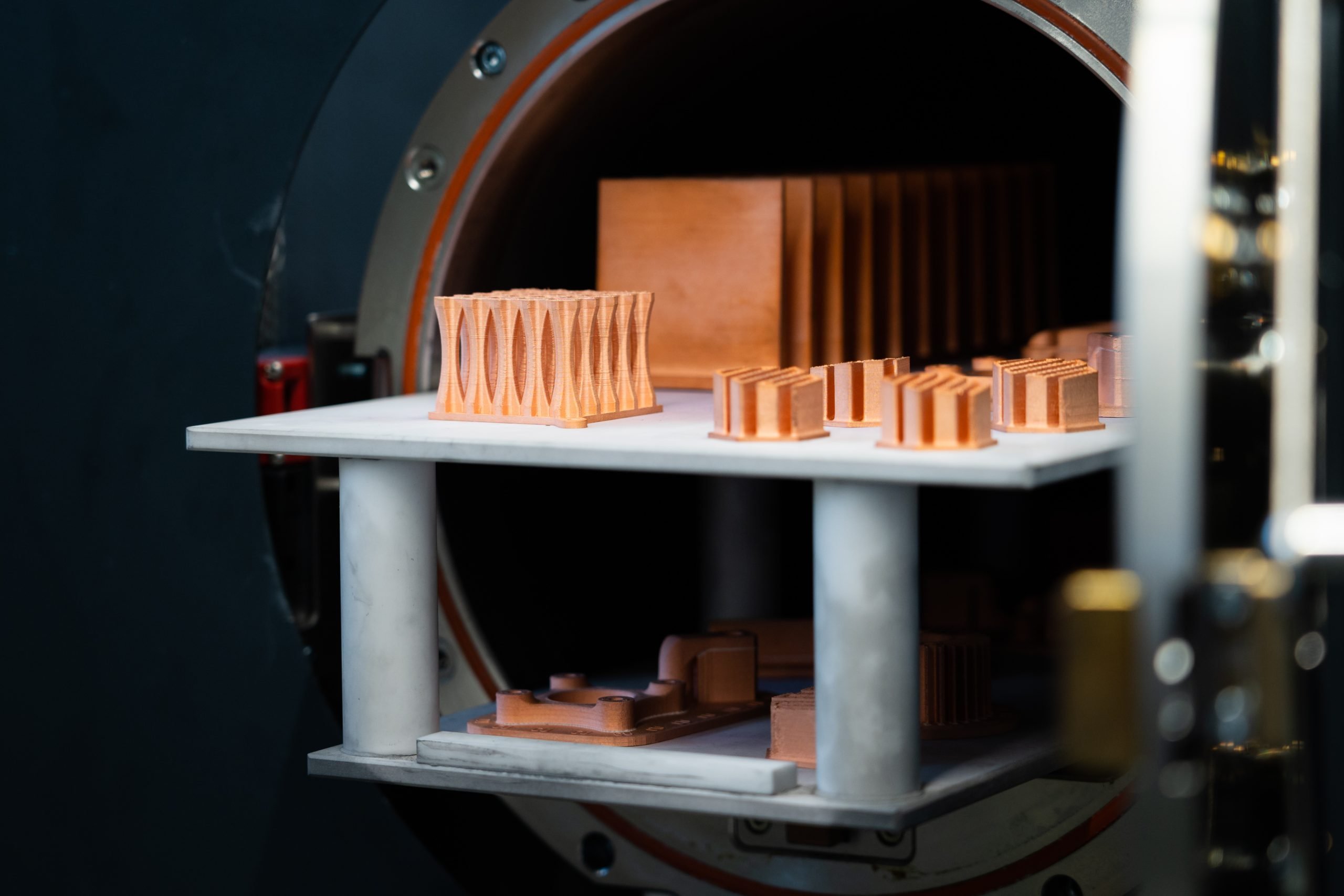

To use Araqev’s software, customers upload their nominal design files and scanned point cloud data from their printed products.

“Our software uses these inputs to fit machine learning models that can simulate shape deviations for future printed products,” Sabbaghi said. “Furthermore, the machine learning models enable our software to derive modifications to the nominal designs, known as compensation plans, so that when the modified designs are printed, they will exhibit fewer shape deviations compared to the case when the original designs are printed.”

Manufacturing on Demand

Araqev’s algorithms also enable the transfer of knowledge, encoded via machine learning models, across different materials, printers, and shapes in additive manufacturing systems

“This means that our software enables a comprehensive platform for a customer to improve quality for their entire system,” Sabbaghi said.

“The power and cost-effectiveness of our algorithms were most recently demonstrated via two validation experiments for the Markforged Metal X 3D printer involving 17-4 PH stainless steel products,” Sabbaghi said. “Our algorithms reduced shape inaccuracies by 30% to 60%, depending on the geometry in at most two iterations, with three training shapes and one or two test shapes for a specific geometry involved across the iterations.”

Araqev is establishing direct partnerships with 3D printing manufacturers and companies. This, Sabbaghi said, will enable the company to scale quickly.

“We will establish licensing contracts after demonstrating to the companies the savings and benefits that we can offer for their processes,” Sabbaghi said. “These partners will incorporate our software into their systems and sell them to their customers, which provides us with a significant customer channel.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment