3DQue has plans to expand Quinly to be compatible with more Prusa printers including the Prusa Mini, which is currently in the beta testing phase, making it the newest addition to the largest multi-platform 3D printer automation beta program in the world.

“The Quinly for Prusa Mini beta is the largest yet,” says Mateo Pekic, co-founder. “Customers with Quinly for Prusa MK3S wanted to use Quinly on their Prusa Mini’s as well. Since the Prusa Mini is popular for print farms it was the logical next step for automation, but we were still blown away by the response.”

Manufacturing on Demand

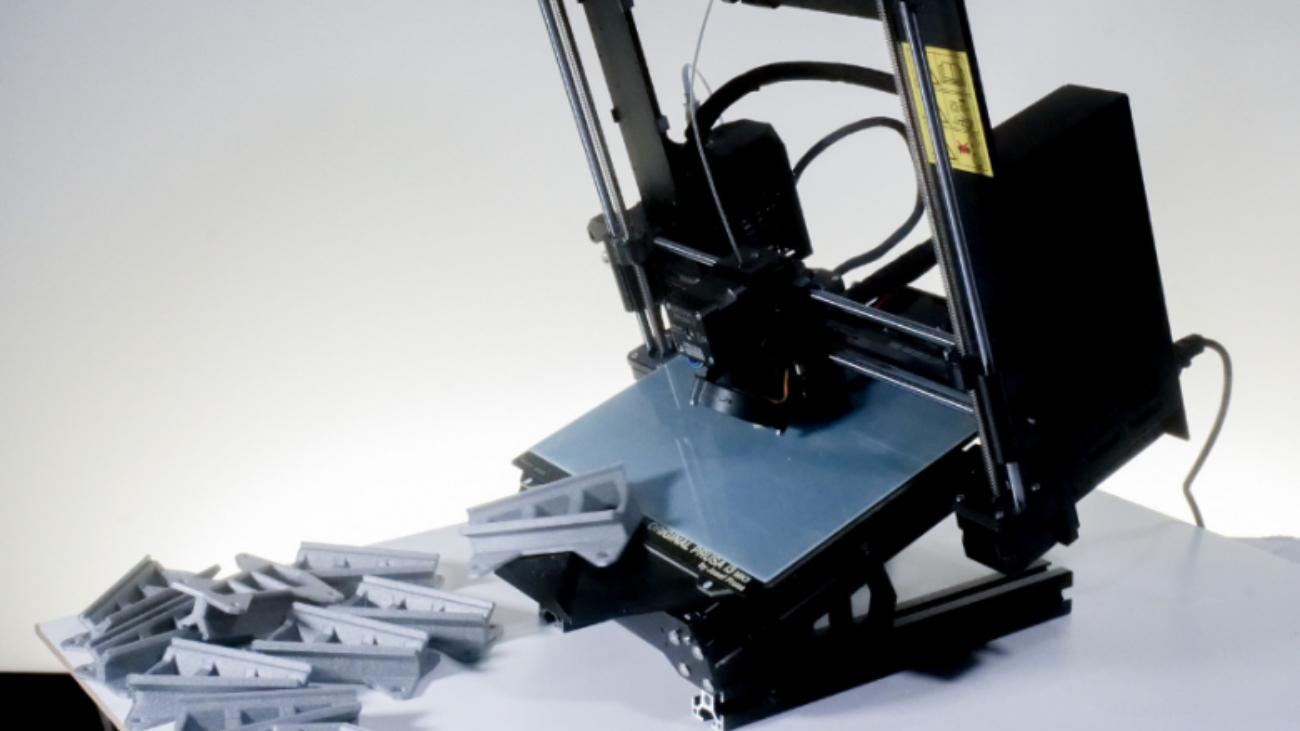

3DQue looks forward to the day when Quinly automation will be offered as a standard feature in 3D printers. Meanwhile, 3DQue continues to develop Quinly for a wide variety of 3D printers with the Ultimaker S5 and Prusa Mini expected to be out of beta in the next few weeks and new beta’s opening for Artillery Genius, Ender 3 S1, CR-10 Smart, and Ender 3 Max. By late spring, Quinly will be able to automate over 50% of the most popular 3D printers sold.

3DQue is a technology startup focused on building a more secure, innovative and sustainable manufacturing sector with automation. They see a world where smart automation operates production, where people focus on growing their business, not managing it, where global events don’t stop business in its tracks.

3DQue has grown quickly with customers exceeding installed capacity of more than 5 million automated print hours per year freeing up more than 250 years of operator time. Now functional and end-use commercial, industrial and consumer goods can be designed and produced anywhere in the world at low cost, accelerating innovation at scale.

You might also like:

MX3D M1 Metal AM System to be used for automotive parts: The acquisition represents the continuation of a series of successful R&D projects by BMW Group in collaboration with MX3D. The company said it is very much looking forward to the upcoming WAAM projects to be conducted by BMW Group and made possible by their new in-house WAAM capabilities.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: VoxelMatters

Leave A Comment