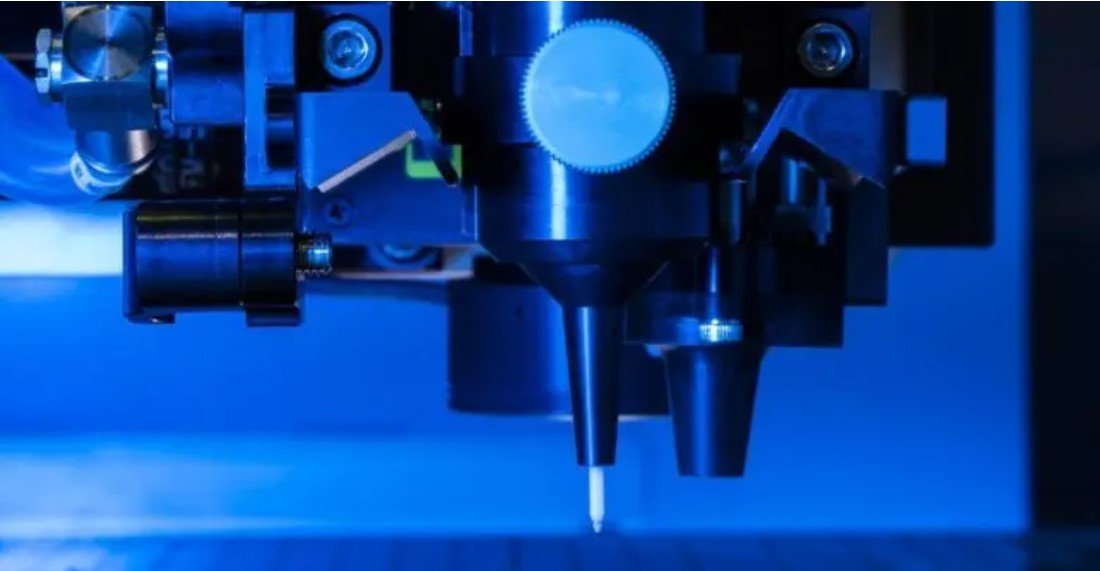

The Air Force Sustainment Center at Tinker Air Force base has awarded Optomec a $500,000 process development contract for the Additive Repair of jet engine components used in the F-15 and F-16 fighters. The solution will rely on Optomec’s LENS technology, a metal additive manufacturing technique based on powder-fed directed energy deposition (DED), together with proprietary enabling machine capabilities including advanced vision and distortion compensation software, Controlled Atmosphere processing, and batch automation using oxygen-free material handling.

The effort will focus on developing optimized process parameters and procedures to enable the Additive Repair of turbine blades, made from both titanium and nickel-base superalloys. These printable “Recipes” and “Libraries” will be implemented in conjunction with the delivery of an advanced automated Turbine Blade Repair machine. The program has a projected ROI of 184%, with a payback period of fewer than 2 years, and could save the Air Force many millions of dollars as it maintains its fleet of more than 5,000 aircraft with an average age of 28 years.

Optomec’s additive manufacturing repair processes are currently used in high volume production for other turbine engine parts worldwide, having repaired more than 10 million components over the last 20 years. This project will extend Optomec’s capability with regard to high-volume titanium repair which must be conducted in oxygen-free environments to ensure proper metallurgy and mechanical performance. Titanium demand in aircraft engines is increasing in both the military and commercial aviation markets.

Manufacturing on Demand

“The turbine industry has already widely adopted Optomec’s automated DED solution for high volume nickel alloy repair of aviation parts; meanwhile Optomec has worked out the process recipes for titanium repair.” said Jamie Hanson, VP of Business Development, “This solution essentially takes Optomec’s titanium repair process to high volume levels where it will have a major impact on lowering maintenance costs as engine OEMs use more and more titanium.”

Optomec offers dozens of turn-key process recipes for a variety of common alloys and applications. These process recipes help production customers drastically shorten the adoption time for implementing Additive Manufacturing solutions to the plant floor, saving customers an average of 6 months of process development.

Optomec is a privately-held, rapidly growing supplier of Additive Manufacturing systems. Optomec’s patented Aerosol Jet Systems for printed electronics and LENS and Huffman brand 3D Printers for metal components are used by industry to reduce product cost and improve performance. Together, these unique printing solutions work with the broadest spectrum of functional materials, ranging from electronic inks to structural metals and even biological matter. Optomec has fielded more than 500 Industrial Printers at more than 300 marquee customers around the world, with production applications in the electronics, energy, life sciences, and aerospace industries.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Andrea Gambini

Leave A Comment