3D Systems Targets PEEK Implants with Acquisition of Kumovis

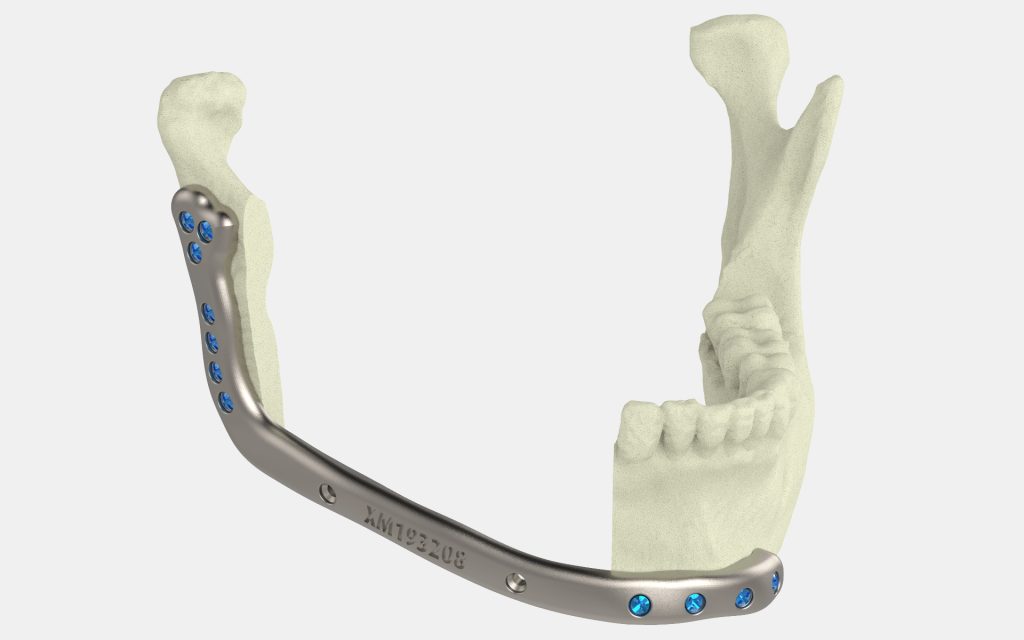

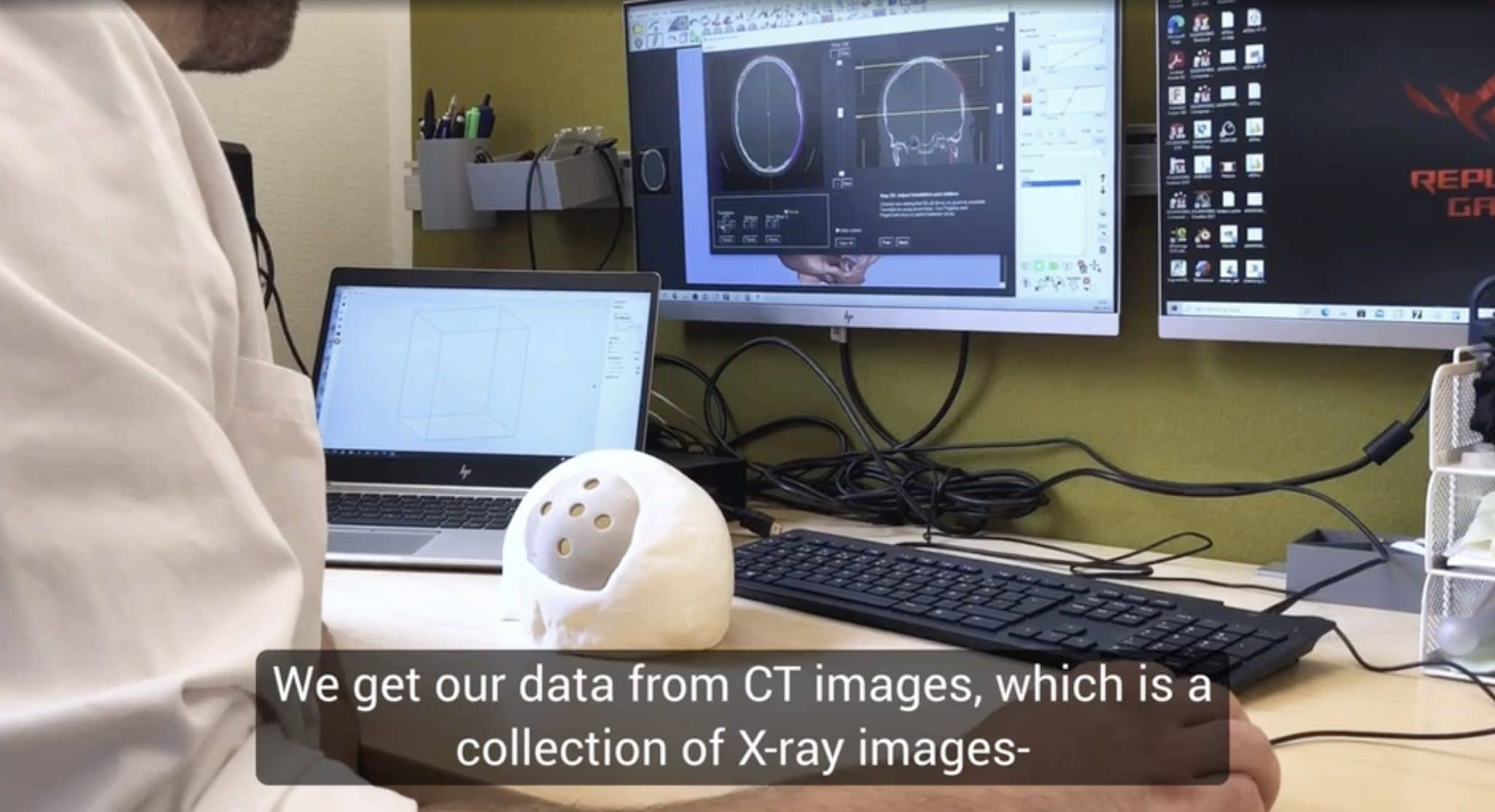

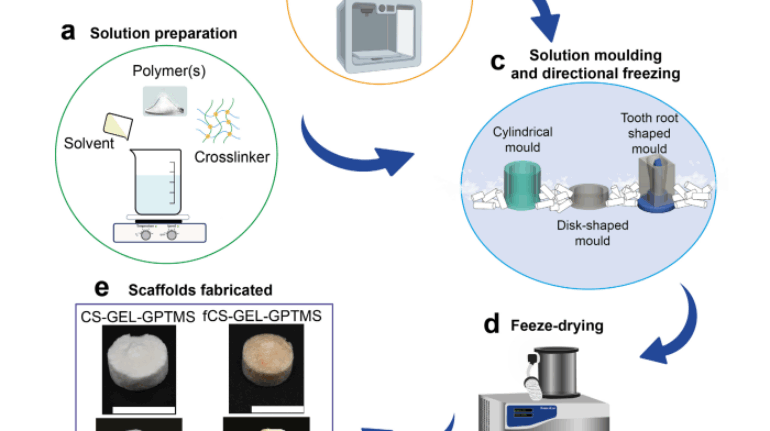

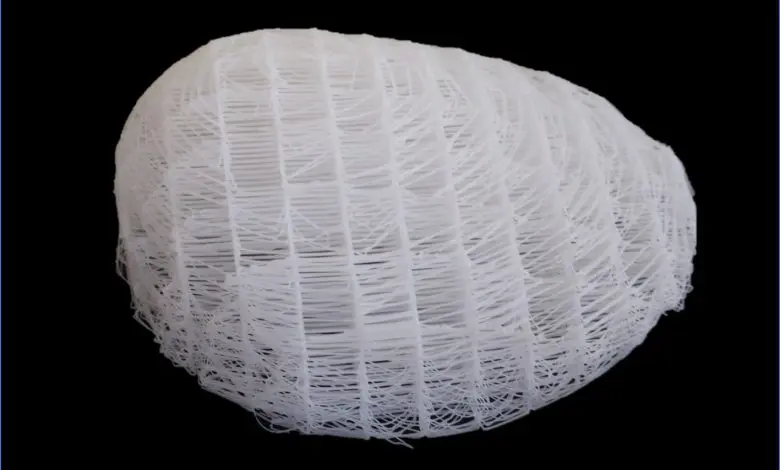

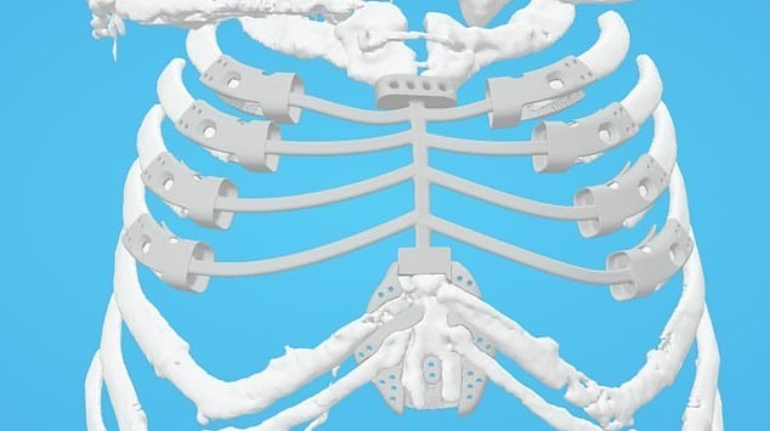

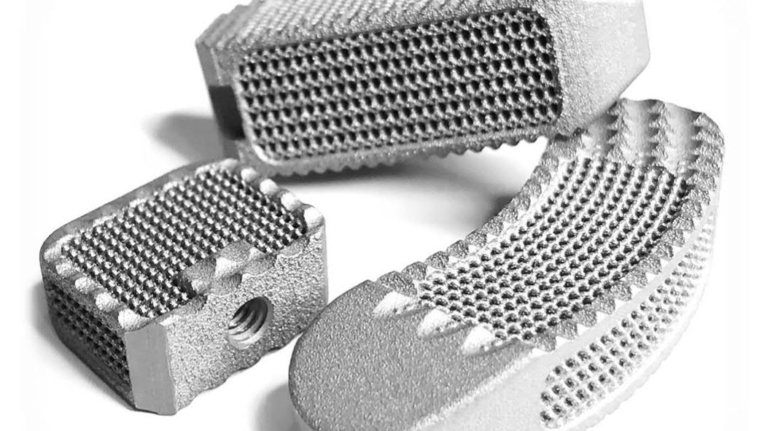

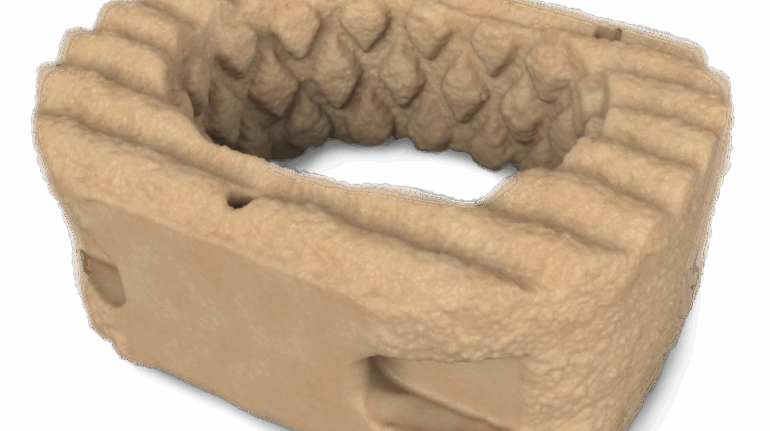

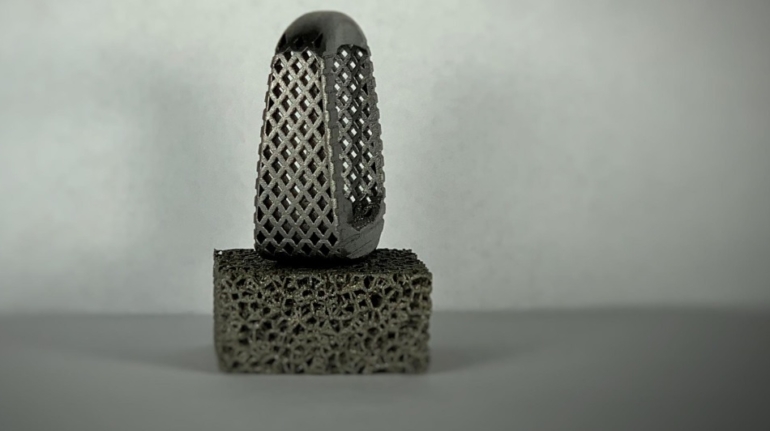

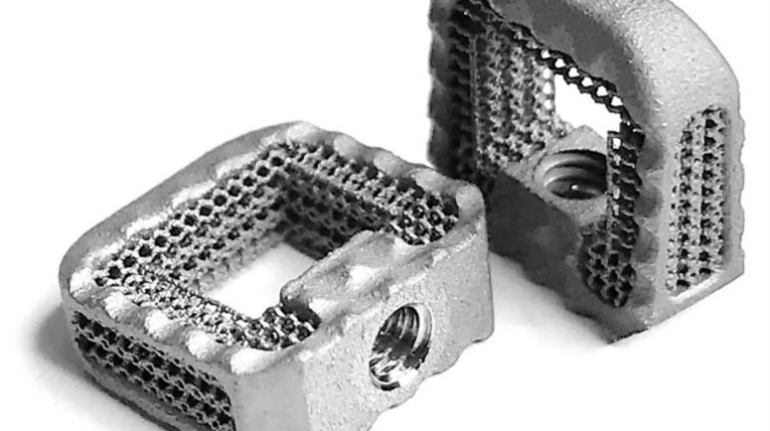

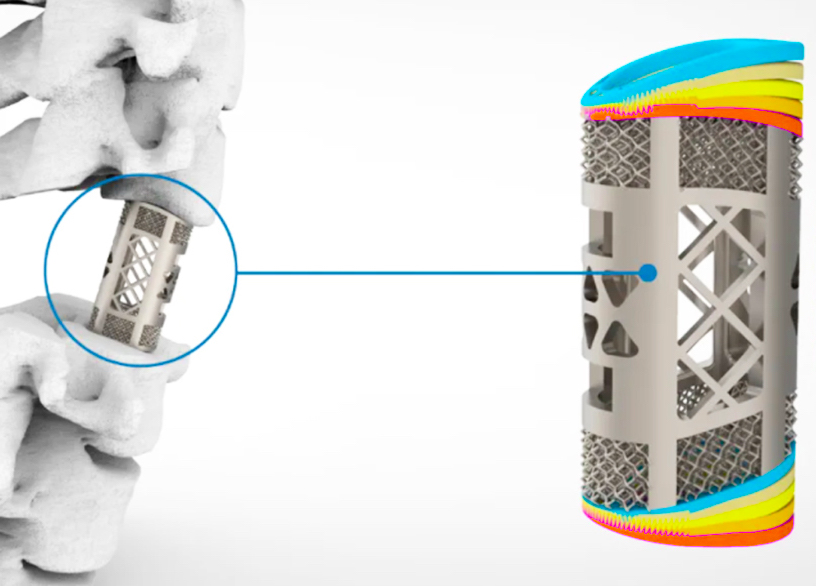

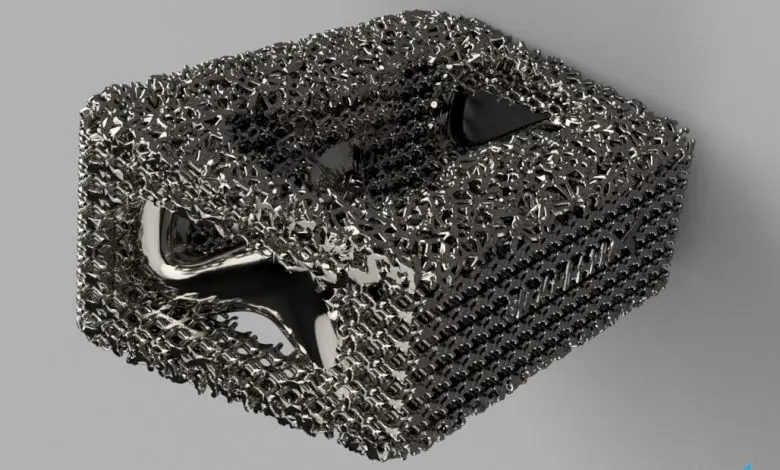

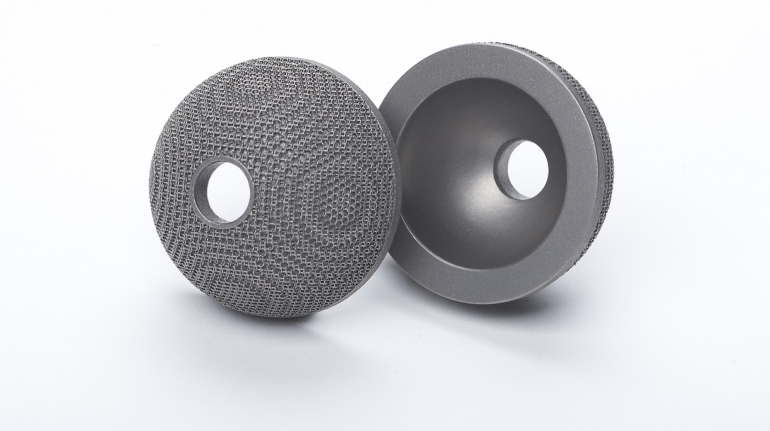

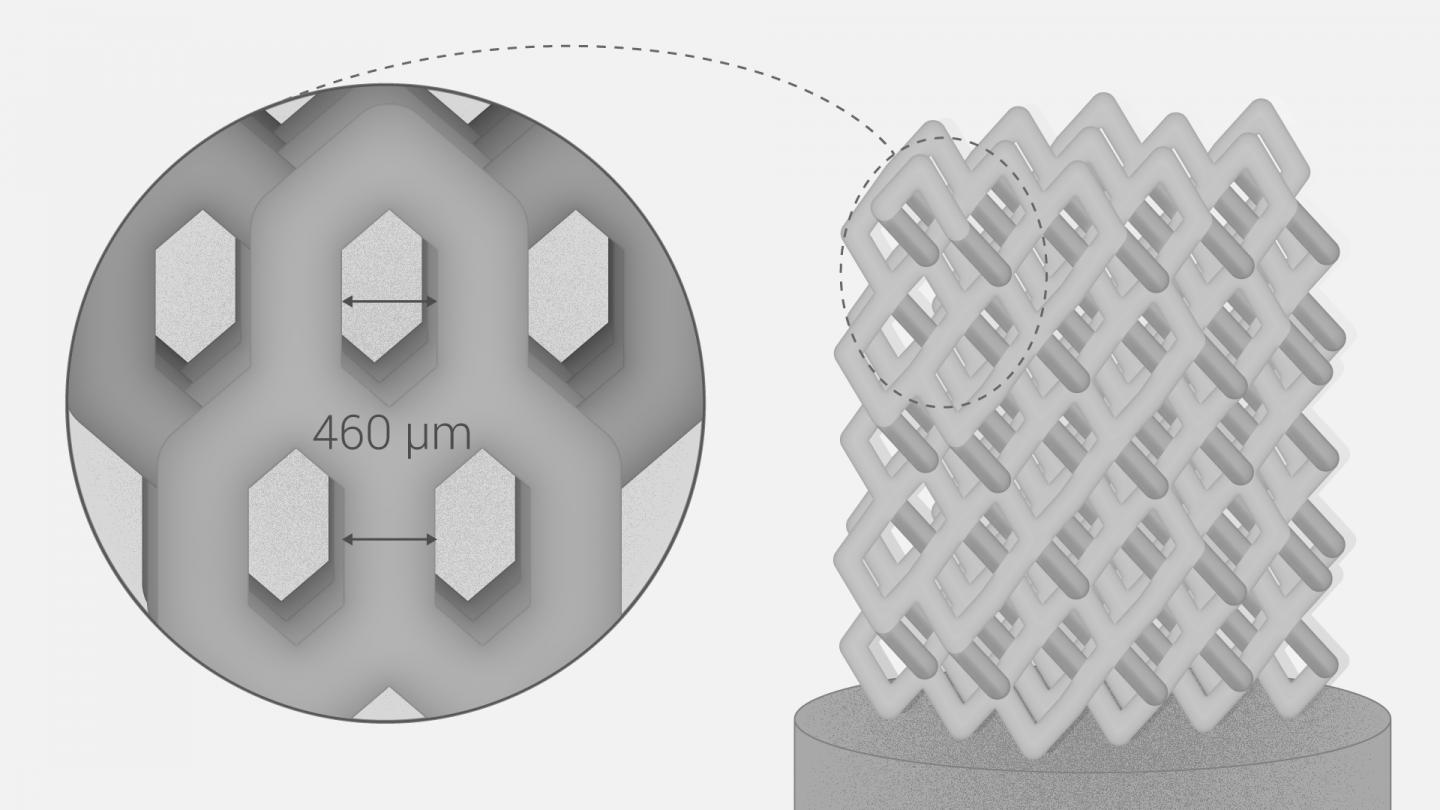

3D Systems (NYSE: DDD) entered into an agreement to acquire Kumovis, a Munich, Germany-based additive manufacturing solutions provider for personalized healthcare applications. Kumovis’ solutions are built upon their unique extrusion technology specifically developed for precision printing of medical-grade, high-performance polymers such as PEEK (polyether ether ketone).