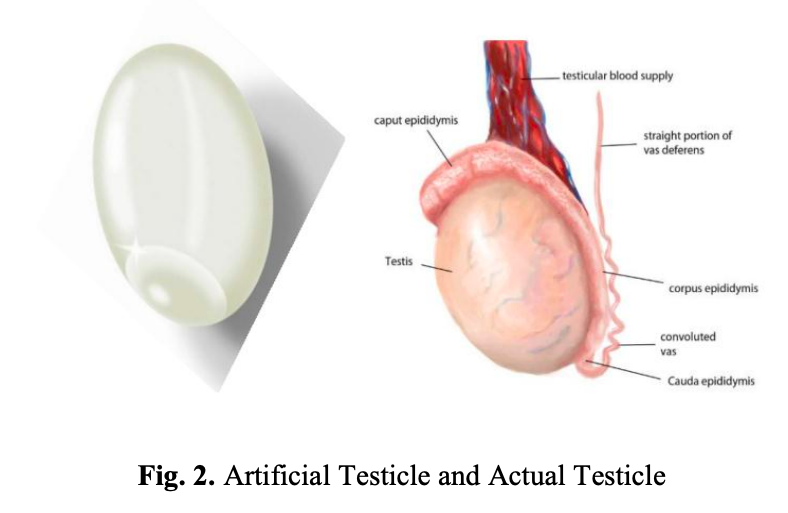

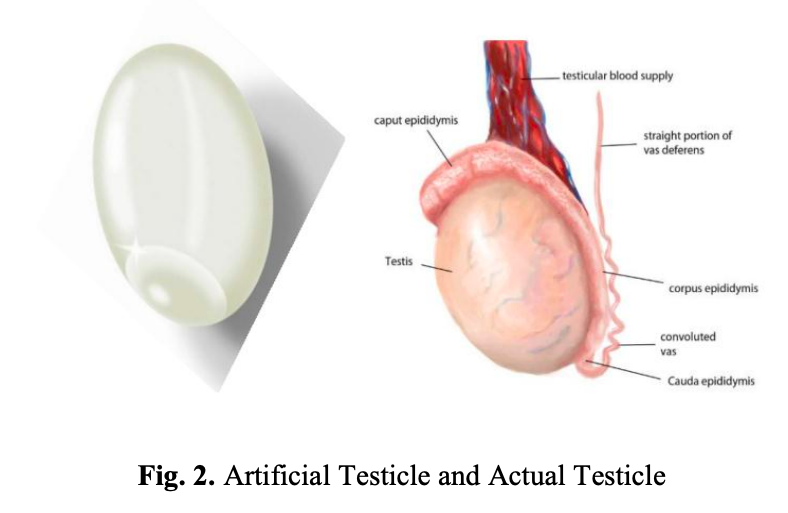

Korean researchers have utilized a 3D printer to fabricate more affordable and customizable artificial testicles for patients in need of a testis transplant.

Unlike conventional replicas, the team’s novel silicone gonads can be 3D printed to match specific patient anatomies, making them a more comfortable and lifelike pelvic prosthetic. Essentially, the researchers’ additive goolies are designed to address a demand for low-cost artificial balls in their native Korea, as well as providing a confidence booster for their wearers.

Fake testicles: the uncomfortable truth

Unfortunately, any number of medical emergencies ranging from tumors to testicular torsions can occur in male genitalia, necessitating their rapid removal. Although doctors fit prosthetics to such patients as a matter of practice, these men often suffer psychological trauma similar to that endured by women after mastectomies.

While replicas don’t play a physical role in the body, their odd shape or appearance can be particularly damaging to the male ego. According to he Korean team, the poor fit of off-the-shelf implants can even have dramatic effects, such as “psychic impotence,” and an “inferiority complex” that causes “personal relationships to fail.”

Additionally, given that many fake testicles come in uniform sizes, they can cause patient discomfort or even escape inside the body, leading to severe complications. The scientists have also highlighted the plight of victims from their native Korea, where U.S. firm AMS has an exclusive deal to supply prosthetic bollock products.

As they’re sold for around 800,000 KRW (or $715 USD), many men have been priced out of new testes, an issue that’s compounded by the fact that surgery isn’t covered by most insurers. To combat this, the Korean team therefore set about developing a novel prosthetic that can be customized to the needs of each patient, while remaining safe for in-vitro use.

Once the team had finished printing their prosthetics, they post-processed and molded them. Photo via the International Journal of Engineering Research and Technology.

3D printing the upgraded implants

Before they commenced printing, the scientists mixed silicone LSC-40 (a polymer used in arts and crafts) with RTV-THINNER, to create a fast-hardening flexible rubber. Once they had formulated the optimal material, the team then used patient data and the Creo Parametric 3D modeling software, to develop small, medium and large-sized testicular models.

The bollocks themselves were later fabricated in three parts, using a 3D printer to ensure a high level of accuracy, before being post-processed and stuck together with red putty. After they’d been processed, the team subsequently subjected their balls to a silicone molding process, to give them a glossy bio-friendly finish.

During testing, the scientists found that the silicone’s ‘split oil’ was an effective cleaning agent, while its high viscosity meant that only a single application was needed. What’s more, the team concluded that, while their ball used similar glues to other prosthetics, their customized nature could make them less prone to failure.

Manufacturing on Demand

The Korean researchers now aim to evaluate the “physical excellence” of their design by surveying future patients that have had their additive family jewels fitted. In future, the team also intend to register their testis prosthetics as medical devices, and commercialize them as a more affordable alternative to expensive U.S. imports.

3D printing and breast retention

Although utilizing 3D printers to create prosthetic testicles does represent a fairly novel use of the technology, it has been deployed in similar ways before to help female cancer sufferers.

A team from the Korean Asan Medical Center, for instance, has 3D printed surgical guides that enable cancer patients to retain more of their breast tissue after surgery. During test procedures, the scientists found that they were able to get as close as 1cm to tumors, enabling them to achieve optimal results for the patients.

Similarly, medical start-up myReflection, has developed a combined 3D scanning and molding method of fabricating personalized breast prosthetics. Made using an ISO-certified outer silicone, the novel additive devices could last up to four years, considerably longer than conventional implants.

Elsewhere, in terms of materials, medical scaffold developer BellaSeno has started using chemical firm Evonik’s RESOMER polymer for breast reconstruction. Leveraging the plastic’s unique biocompatibility, the company is aiming to create implants that can be safely reabsorbed by the human body.

The researchers’ findings are detailed in their paper titled “.”

The research was co-authored by Hyunjun Park, Dongkyun Kim, Byungwoo Lee, Sungho Kim and J. Wang from Pusan National University, Busan National University and Pukyong National University.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment