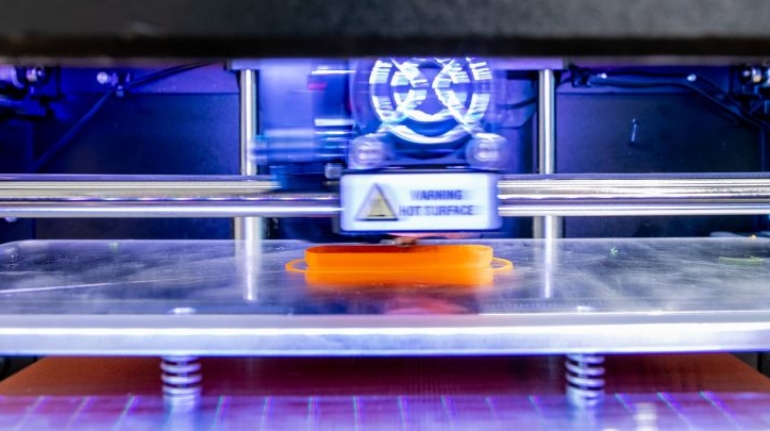

Sakuu Demonstrates High C-rate in its Non-printed Battery

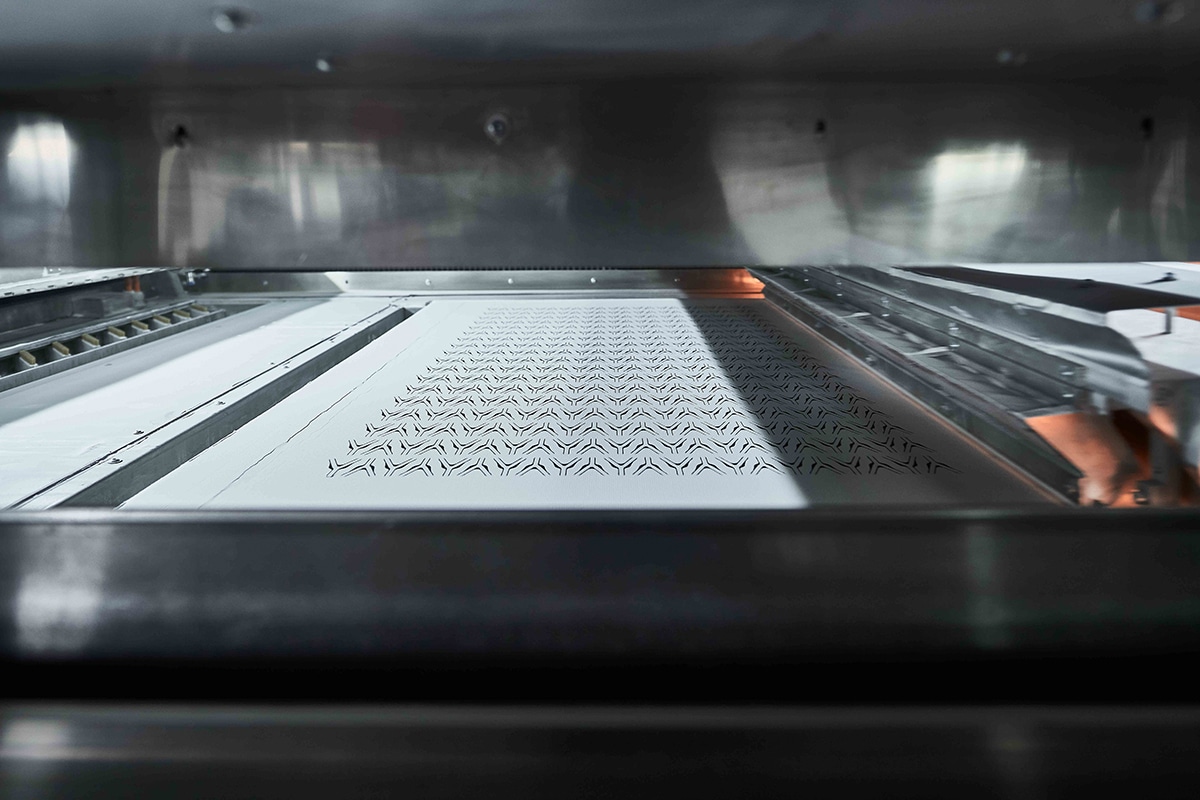

Sakuu Corporation, developer of the world’s first rapid printed battery, today announces that its first-generation non-printed lithium metal battery has achieved continuous 3C discharge rate under extensive testing, marking yet another achievement on the road to mass 3D printed solid state batteries.