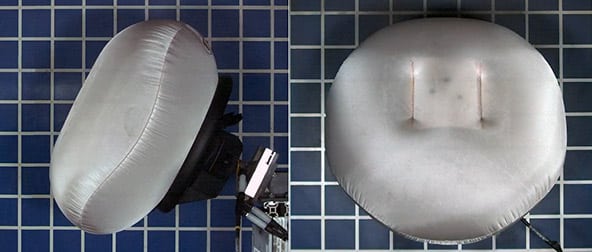

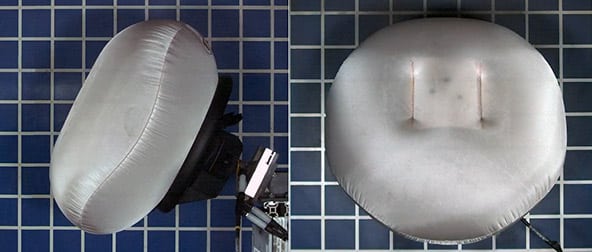

Joyson Safety Systems, a leading provider of mobile safety components, systems and technologies, recently developed its first functional 3D printed driver airbag (DAB) shell prototype using CRP Technology’s selective laser sintering (SLS) and Windform composite materials.

Joyson Safety Systems has a history of groundbreaking innovations in mobile safety solutions (such as airbags, seat belts, safety electronics, etc.) in the automotive and non-automotive markets. It is worth mentioning that it is the first manufacturer to provide autonomous driving steering wheels (HOD) to leading OEMs in North America and Europe. In this case, the company’s core innovation team hopes to quickly develop prototypes for its airbag shells, and then turn to additive manufacturing to explore new processes and materials.

Traditionally, the airbag shell is injection molded, the injection-molded material is polyamide, with 40% glass fiber reinforced PA6-GF40. The DAB system needs to be deployed within 30 to 50 milliseconds to prevent injury to the driver. It consists of an inflator, airbag cushion, shroud, and housing mounted on the steering wheel. The performance of this system is very important. It is an important safety component of the vehicle, which needs to have sufficient strength, impact resistance and stability under heat and various other environmental conditions. Samer Ziadeh and Daniel Alt of the core innovation team explained the DAB requirements,

“During and after deploying the airbag system, in addition to fixing the inflator and airbag cushion in place, they also have to withstand a large amount of dynamic load. This load is generated due to the pressure required to inflate the airbag, therefore, Large stresses will be directly applied to the airbag system, especially the DAB housing. The test procedure is usually carried out in various temperatures range from -35°C to 85°C.”

When searching for suitable materials for DAB, the team found that CRP Technology’s patented Windform series of high-performance SLS materials are more suitable for its requirements:

“…after running some market analysis in order to find out the most suitable material and process that could deliver the required performance, we came across the Windform TOP-LINE family of composite material and, specifically, the Windform SP. Windform SP brought our attention to the fact that it’s a material produced from polyamide PA grades, reinforced with Carbon fiber or fiber-glass, as a powder form material, and it has almost the required and even better performance for our application.”

Windform has become a high-performance SLS material and has been used in fields such as Mercedes AMG Petronas’ motorsports, automotive and aerospace, and NASA. Windform materials not only meet the strict requirements for aerospace or motorsports, but can also be post-processed by CNC machining or using tools and equipment. CRP has become a leader in SLS high-performance AM materials with Windform, applying its expertise in a range of proven applications from medical to drones, from satellites to electric motorcycles.

The application is the first functional prototype of Joyson Safety Systems using SLS and composite materials to produce DAB housings in a short time.