May 17-19 marks the return of the largest and most influential additive manufacturing event, RAPID + TCT in Detroit, Michigan. The three-day event allows firms to showcase technological capabilities in the booming 3D printing trade. World Industry leaders and innovators will be present to display new technologies and processes geared to educate new and existing users.

Youngstown, Ohio-based JuggerBot 3D, a manufacturer of industrial-grade 3D printers, will host an exhibit at the event to display three new technologies that further expand on the production capabilities of pellet-based 3d printing.

Fused granulated fabrication duplication mode

At RAPID + TCT 2022 new technological processes are unveiled to propel the additive manufacturing industry forward. JuggerBot 3D plans to do nothing short of this by debuting the first Fused Granulated Fabrication (FGF) printer equipped with a multi-position dual extrusion system. The release of this technology provides operators with the ability to switch between Multi-material Mode and Duplication Mode printing within a single system.

Ultimately, the multi-position dual extrusion system enables operators build large, complex parts with two materials in Multi-material Mode, while also enabling a higher rate of low-volume production using Duplication Mode.

Manufacturing on Demand

Model 19 pellet extruder upgrade

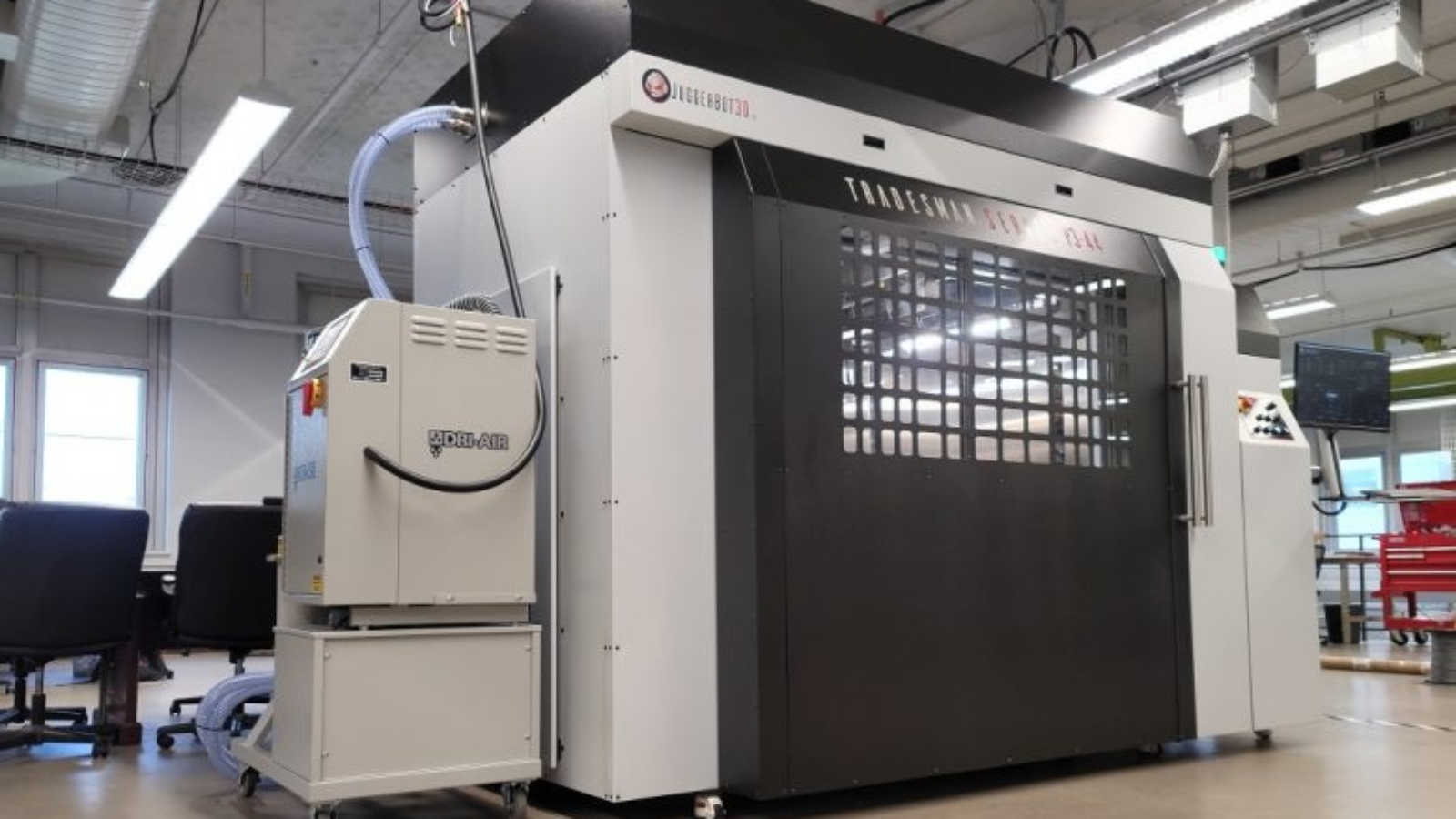

Amongst new technologies shown at RAPID + TCT will be JuggerBot 3D’s Model 19 pellet extrusion system upgrade for their Tradesman Series™ models. The Model 19 extruder generates compatibility with nozzles up to a 10mm orifice for faster printing and larger parts. For JuggerBot, this new technology can double operator’s output, achieving a maximum through up to 30 pounds per hour.

In addition, the Model 19 improves the uniform heating and mixing of materials, which are critical to part quality and reliability with FGF printing.

Bead characterization system (BCS)

The final feature shown at this year’s RAPID + TCT event will be the showcase of JuggerBot 3D’s Bead Characterization System (BCS). The Bead Characterization System (BCS) has been developed to help operators efficiently identify parameters for the optimal flow rate of a specific material–machine configuration combo. Currently, this is done through a very manual process, requiring operators that are well versed in the technology, material, and process to tune settings through trial and error. With the BCS, data can be captured, stored, and called upon later by Tradesman Series™ P3-44 users electing to utilize Bead Area Mode to generate tool paths.

Schedule time to see these at, or after, RAPID TCT by visiting JuggerBot 3D’s website.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment