3D print applications have revolutionized industries from architecture, construction, furniture design, and fashion. Last year, 3D print fabrication aided in provided medical professionals, patients, and facilities with PPE during the COVID-19 pandemic. As fabrication continues to develop and expand, a company based in Burlington, MA, has found a way to turn upcycled wood byproducts into a promising new avenue for additive manufacturing.

Forust, an exclusively owned subsidiary of 3D printing and rapid prototyping Massachusetts-based company Desktop Metal creates “high-volume additive manufacturing of end-use wood parts possible.” Launched in 2021, Forust’s system “upcycles wood waste from the approximately 15 billion trees cut down each year1into luxurious, high-quality, end-use wood parts that can be used in a variety of industries, from consumer goods and furniture to home goods and automotive luxury interiors.”

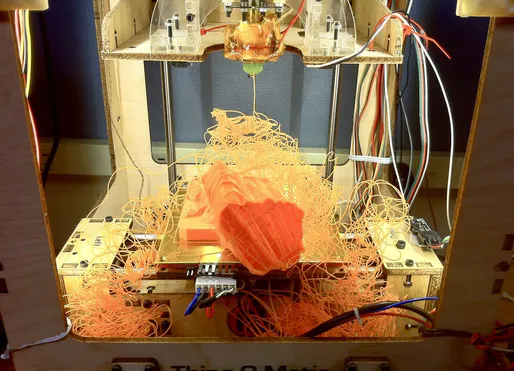

There may have been improvements with 3D printing applications, but the fabrication tool has undergone some criticism due to its use of “standard” plastics like PLA, PET, and ABA. However, 3D fabrication specialists and research teams worldwide have explored sustainable and alternative printing materials like hemp, mushrooms, and other biomaterials. While wood-based filaments for printing are not a new application, what Forust has developed is a way to not only provide an affordable, reliable, and sustainable 3D printing option but mitigate carbon emissions. “We are applying these peed, precision and quality of binder jetting to produce strong, lightweight wood components derived from two wood waste streams-sawdust and lignin,” explains Forust.

Cautious of the environmental impacts of 3D printing, Forust is keen on changing the cycle of wood waste. With their twofold approach, the company aims at reducing the amount of sawdust sent to be incinerated or sent to landfills by processing the material for 3D printing. While sawdust is biodegradable, Forust points out on their site that sawdust’s harmful effects on the environment while in landfills. In large quantities, the burned wood waste contributes to additional air pollution. “As it decomposes, sawdust releases high concentrations of lignin and fatty acids, which can contaminate water supplies, potentially poisoning wildlife and micro-organisms,” explains Forust

According to a statement in Business Wire, Andrew Jeffery (Co-inventor and CEO of Forust) shared, “The inspiration for Forust was to begin with sawdust and end with forests. Our process is based on extensive research conducted over the past decade in the field of hardwood lumber, leading to complex and elegant finished structures. Through advanced CAD software, proprietary materials, and Desktop Metal binder jetting mass production platforms, we can now manufacture beautiful, functional, and innovative wood products for a variety of architectural, interior, and home goods applications from upcycled wood byproducts.”

Forust’s 3D wood printing methods range from consumer goods to luxury interiors applications. Renowned industrial designer Yves Béhar has already teamed with Forust in a collaborative product line called The Vine collection. Béhar shared with Business Wire, “As a designer, I use a lot of wood, and being able to use a product made from sawdust and lignin is an amazing resource. “The future of design and production really hinges on new technologies coming on and allowing designers to approach materials and manufacturing in ways that are sustainable, in ways that are low carbon footprint, in ways that we are using waste instead of cutting down more trees or extracting more oil out of the soil.

Leave A Comment