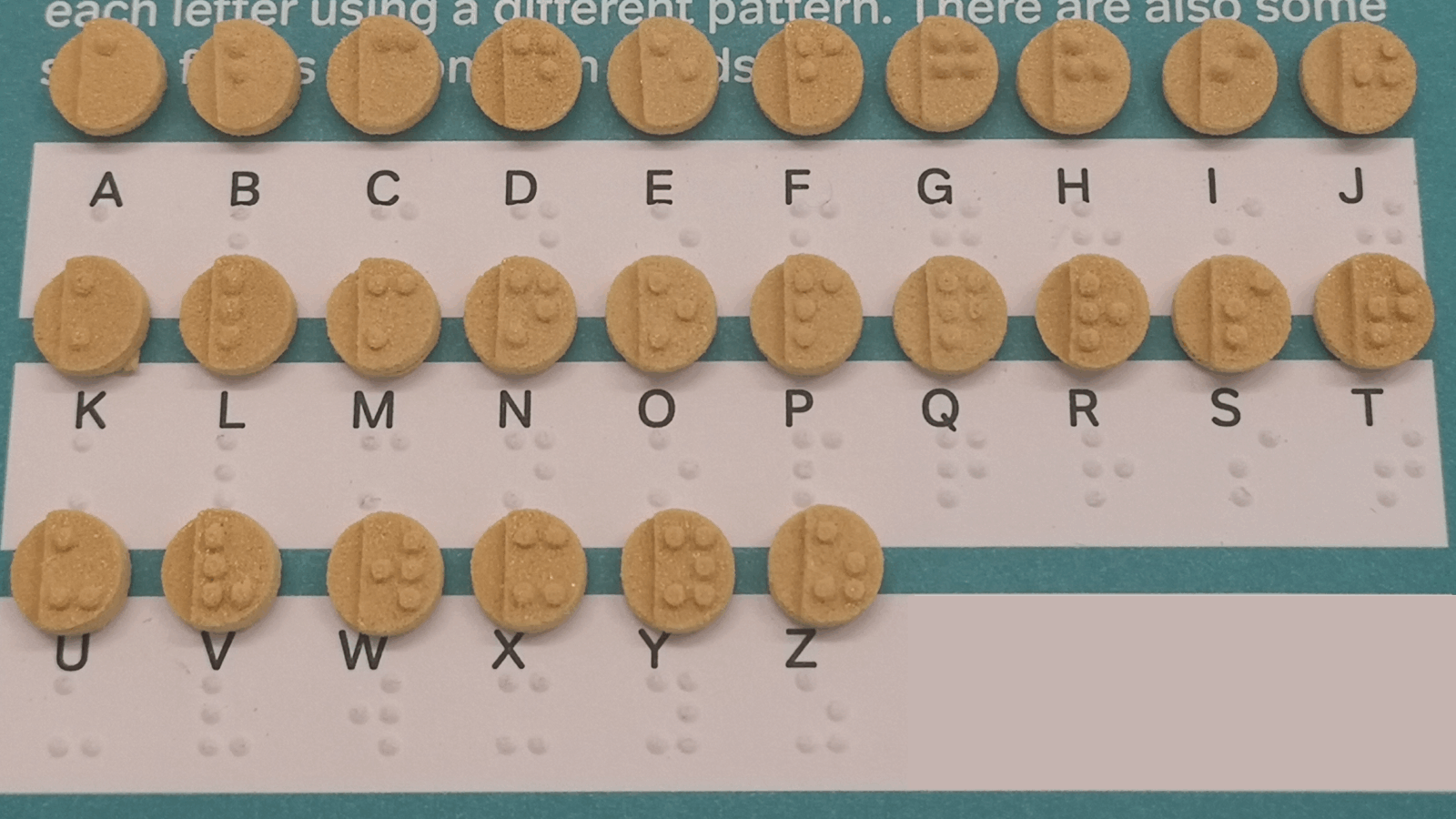

Pharmaceutical 3D printing specialist FabRx has produced orodispersible 3D printed tablets, called Printlets, which are designed with Braille and Moon patterns on the surface to aid medicine taking for patients with visual impairment.

The FabRx and University College London (UCL) team used a Selective Laser Sintering (SLS) 3D printing process to create the Printlets. The Printlets’ readability has been verified by a blind member of staff at the Royal National Institute of the Blind (RNIB), where the staff member confirmed that all the Braille and Moon Printlets were easy to read and stable upon handling.

Utilizing SLS technology

FabRx’s SLS technology works by superficially melting the powder particles together using a laser beam, and through selecting the ideal laser and thermal settings, the team was able to produce tablets with sufficient mechanical properties that allow handling while maintaining high porosity to allow quick dissolution.

“Because the Printlets rapidly disintegrate in the mouth, the patients are not expected to experience any discomfort upon swallowing due to the presence of the patterns,” explained UCL PHD student and first author of the study, Atheer Awad. “In addition, this allows these medications to be taken independently without the need for water or the help of a carer.”

According to Awad, as the process is controlled via a 3D computer-aided software it is easy to change the design of the Printlets to allow for various shapes and patterns to be printed as required. The tablets are printed using FabRx’s M3DIMAKER 3D printer, first introduced at ILMAC Exhibition in September 2019, and which is designed specifically for the manufacture of personalized drug delivery devices.

With the majority of modern drug delivery devices mass-manufactured via conventional methods in a ‘one size fits all’ approach, 3D printing has opened up the significant potential for personalization of dosages and the ability to meet age and physique-dependent medical formulations.

Last year, FabRx developed personalized medicine for children with the rare metabolic disorder, maple syrup urine disease (MSUD), offering a rapid and automated alternative for the preparation of tailored therapeutic dosages.

Aiding self-administration

In addition to printing Braille onto the tablet’s surface, The FabRx and UCL team have been investigating how the Printlets can be designed in different shapes to offer additional details, such as dosage. This concept aims to provide the patient with further information than what the small surface area of the Printlets can, upon which the size of the pattern that can be printed is limited.

“We wanted to make use of one of the common practices that blind patients often utilize; which is using shapes to identify colors,” said Awad. “So, we used the same concept but as a reference to medical use and dosing regimen. In doing so, we are eliminating the need for patients to constantly refer to paper packages and reducing the number of errors associated with the removal of medications from original packages.”

Manufacturing on Demand

During the study, the Printlets were found to retain their original mechanical properties and dissolution characteristics, despite the variation in shape and pattern, and disintegrated within approximately five seconds. Through this development, FabRx believes the Printlets could help safeguard the use of medications for visually-impaired patients while supporting self-administration and independence.

The role of Polypharmacy

Polypharmacy, which refers to the administration of more than one medicine, can lead to confusion and errors in medication management, particularly in the case of those with visual impairment. FabRx has investigated using Stereolithography (SLA) to print multiple drugs into the same dosage form to create 3D printed polypills or ‘polyprintlets’.

The use of this novel technology could aid patients in identifying different medications on their own and self-administering them in their correct dosing regimen, according to Awad. Additionally, it is possible that Printlets of multi-drugs could be created if the medications are compatible with one another, which could significantly reduce the frequency of dosing and supporting adherence to treatment.

“In simple terms, the possibilities with this technology are endless,” Awad said. “We can create the medication that is best suited for each individual patient, based on their genetics, medical condition, and preferences.”

Researchers from UCL discovered an unexpected chemical reaction whilst utilizing SLA to stack four drugs designed to treat high blood pressure in a single pill. Within the formulation, Amlodipine was found undetectable upon experimentation, despite the pill being successfully 3D printed.

The study is titled , published in the Additive Manufacturing journal, and co-authored by Xiaoyan Xu, Pamela Robles-Martinez, Christine M. Madla, Alvaro Goyanes, Fanny Joubert, Abdul W. Basit, and Simon Gaisford.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Hayley Everett

Leave A Comment