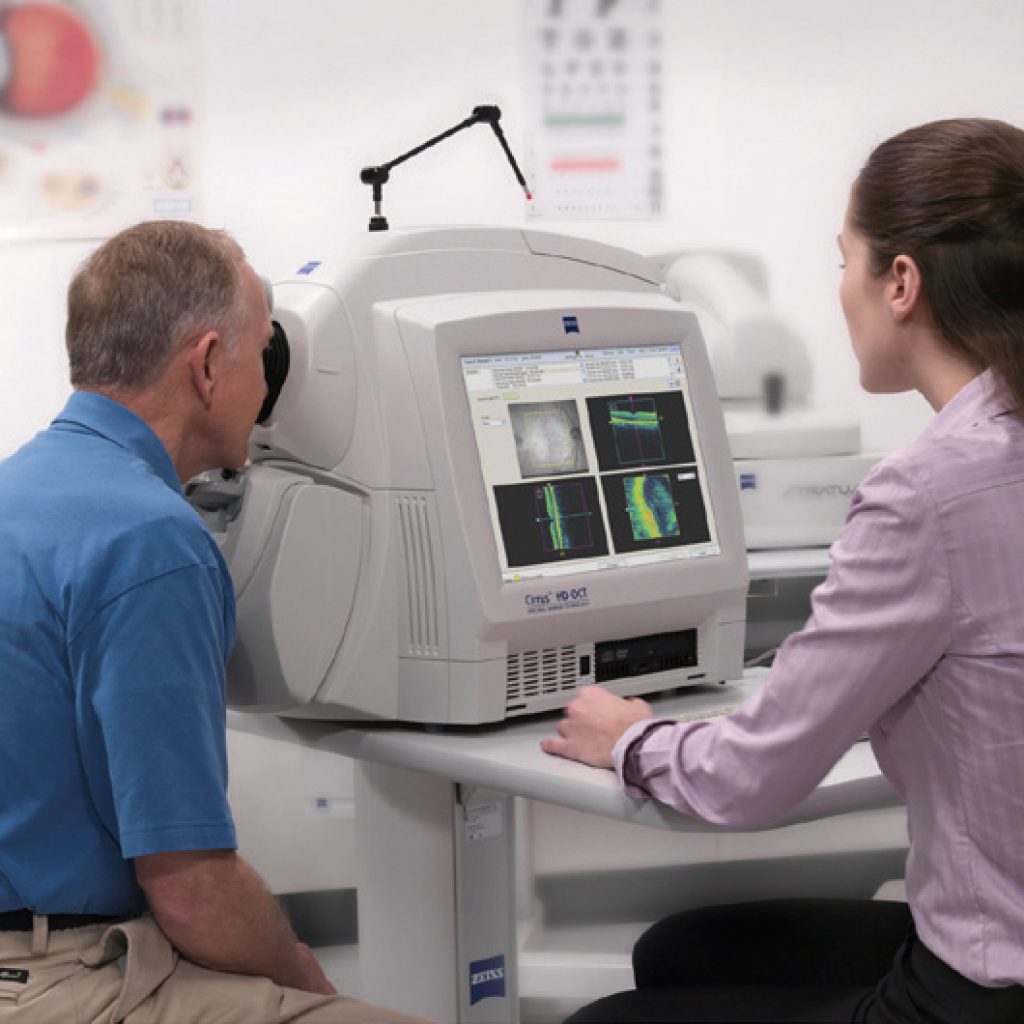

The Medical University of Vienna is set to lead a five-year European project which will see the development of a partly 3D printed mobile ophthalmic (eye-related) imaging device. The engineers and scientists working on the handheld device aim to minitiarize photonic chip technology, bringing down its cost in the process. The project partners hope that by the end of the five years, Optical Coherence Tomography (OCT) will no longer be bound to a stationary clinical setting, but will instead be capable of fitting into a jacket pocket.

Diagnosis of eye diseases

OCT is a well-established method of diagnosing a number of common eye diseases that can lead to blindness if left untreated. These include diabetic retinopathy, glaucoma, and age-related macular degeneration (although this one can’t be stopped entirely). By reducing the size and production costs of the OCT device, accessibility will inherently be increased. The technological advancement will improve the quality of eye care while at the same time relieving some of the strain on healthcare systems.

The project partners believe that, much like integrated electronics have enabled a whole host of mobile electronic devices that we use daily, integrated photonics will have a similar effect with “versatile new applications” – starting with medical imaging. This first step will have implications for ophthalmic care in the short term, but the partners expect the technology to develop into much more.

Microfabrication of freeform optics

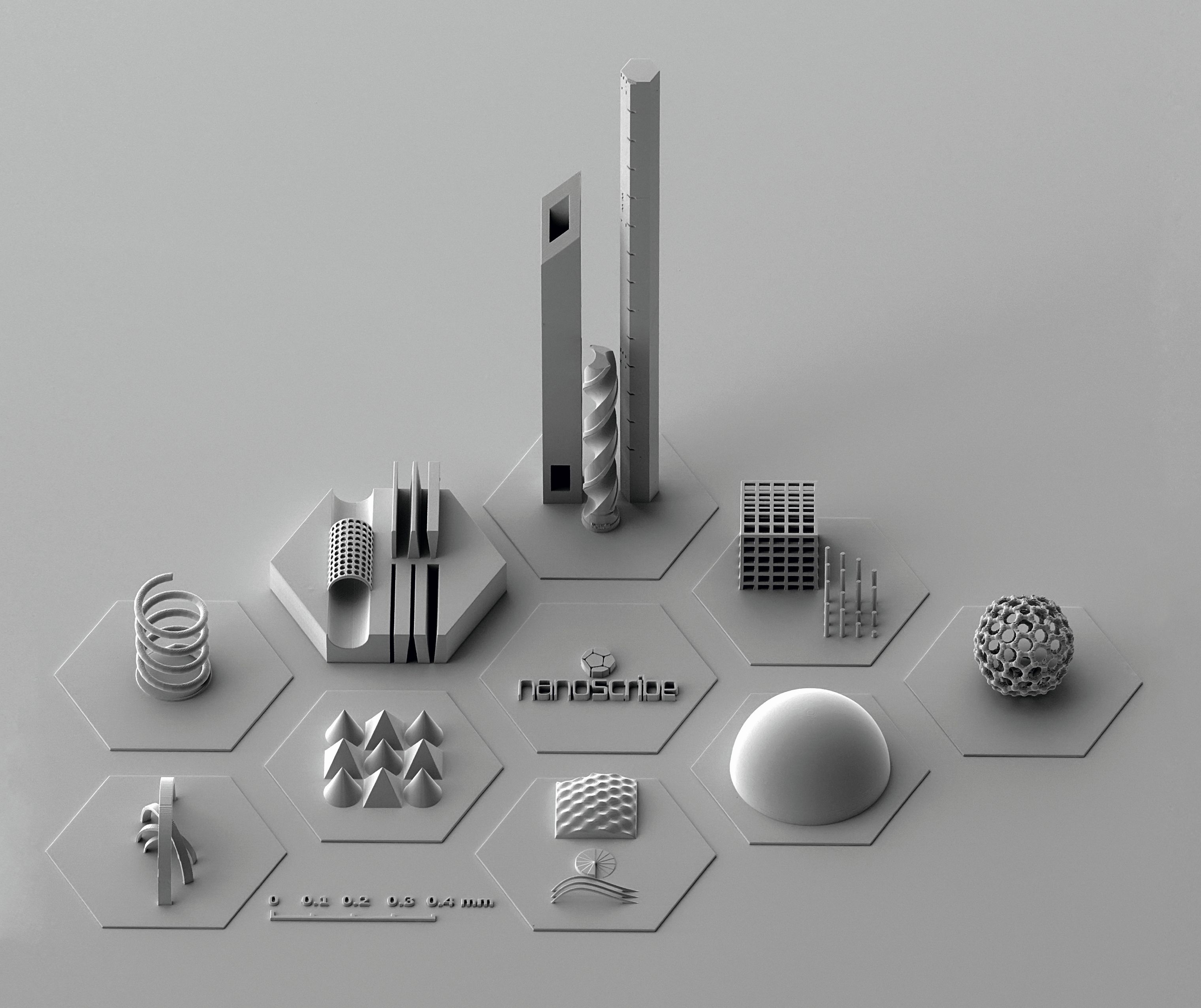

The mobile, low-cost OCT device will be developed by seven partners across four European countries and will receive €6M in funding from Horizon 2020, an EU innovation program. The core integrated photonic chip of the device will be designed by AIT and imec, whereas the chip’s packaging and interface adaptation will be developed by Tyndall National Institute. Nanoscribe will use its micro 3D printing technology to produce the freeform optics of the chip and Innolume will be responsible for developing a novel tunable light source. A handheld prototype system integrating the packaged chip and light source will be realized by Carl Zeiss and the Medical University of Vienna.

Manufacturing on Demand

Every aspect of the mobile device will require a great deal of miniaturization, including the optics, mechanics, and electronics. Once it has been developed, it will be clinically evaluated by the doctors at the Medical University to assess its potential and usability.

Last year, Nanoscribe released its latest microfabrication machine, the Quantum X, featuring two-photon lithography technology. It is capable of fabricating refractive and diffractive optics in the micro-range – sometimes as small as 200 microns. Around the same time, Nanoscribe also joined MiLiQuant, a photonics and quantum research program. The three year project is currently in the process of developing diode laser-based light sources for quantum technology.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Kubi Sertoglu

Leave A Comment