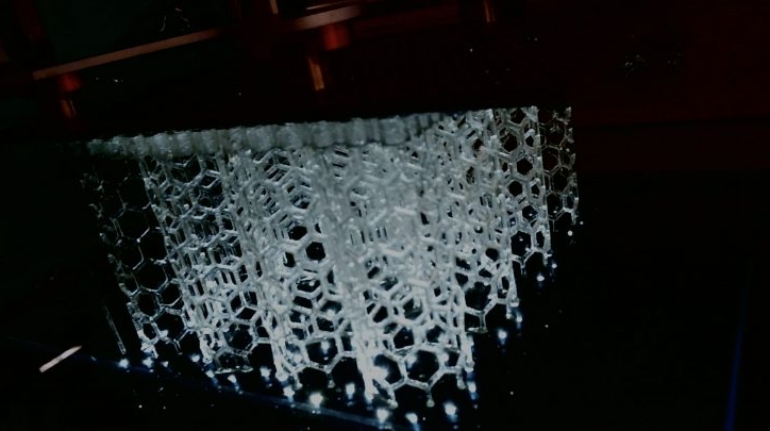

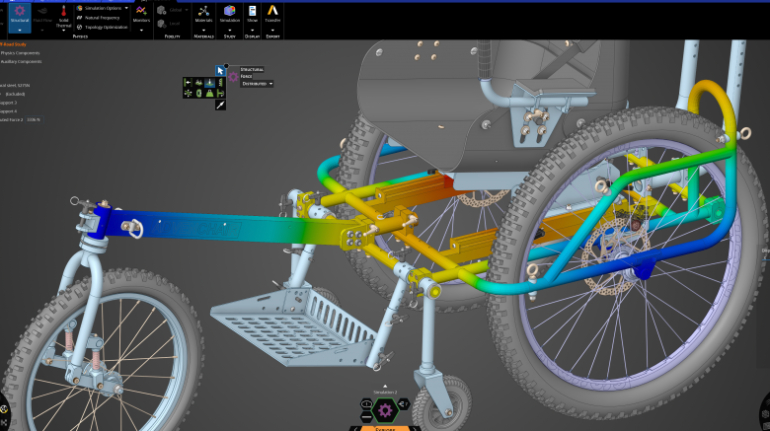

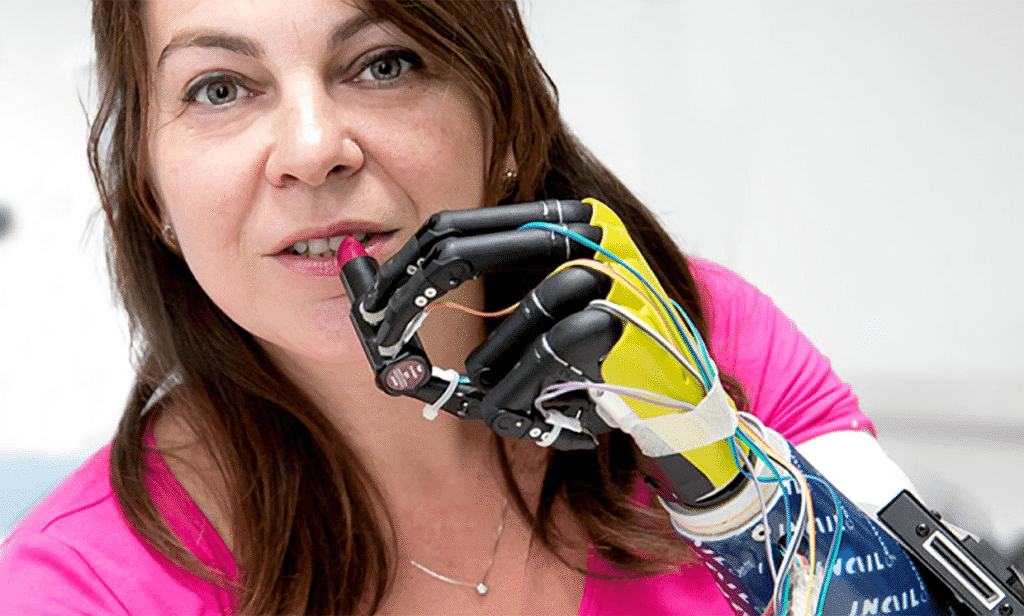

Ireland-based medical device manufacturer Medtronic has announced its intention to acquire France-based Medicrea, a company specializing in the production of patient-specific spinal implants using artificial intelligence and predictive modeling. The companies have entered into a tender offer agreement for Medtronic to purchase all outstanding Medicrea shares (at a price of €7 per share). The deal seems to be moving ahead without issue, as the Boards of Directors of both sides have approved.Once the acquisition of Medicrea goes through, Medtronic will be better positioned to offer its customers state-of-the-art spinal surgery solutions, complementing its own offering of spinal implants, robotics and 3D imaging technology with Medicrea’s AI-driven, custom implants. Medicrea also has an advanced manufacturing facility in Lyon, France dedicated to the development and production of 3D printed titanium patient-specific implants.