Sakuú Corporation Raises $62M to Bring 3D Printed SSBs to Market

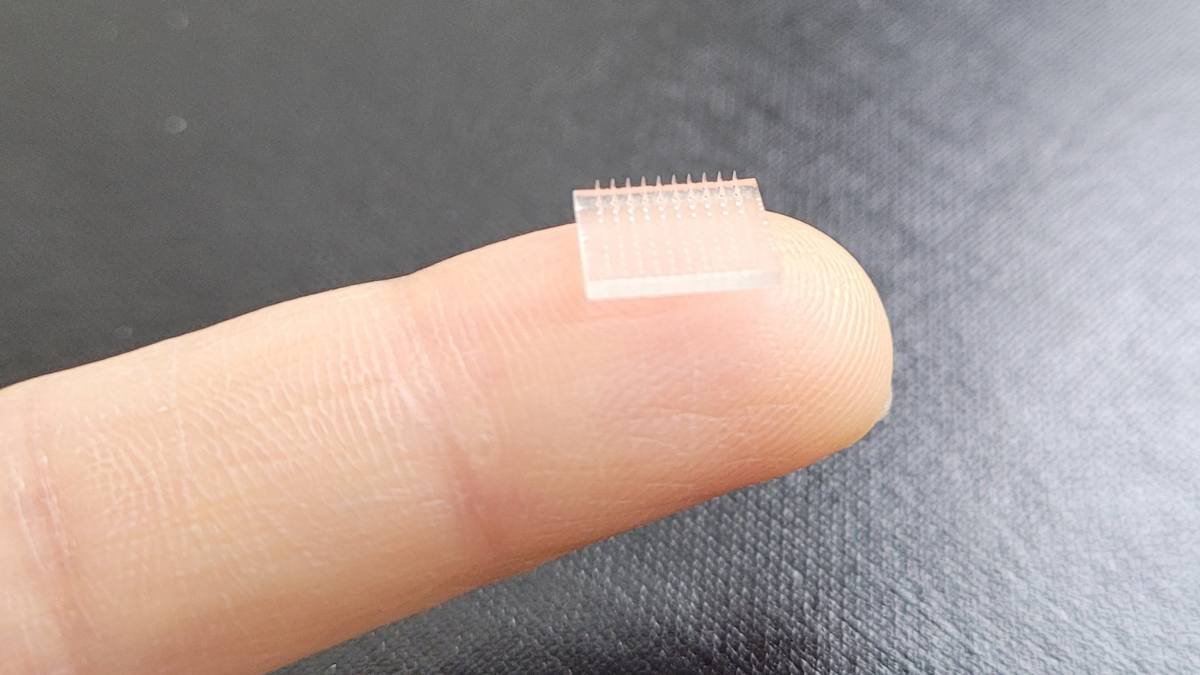

Sakuú Corporation, a company leading the development of an automated multi-material multi-process additive manufacturing to produce 3D printed SSBs (solid-state batteries), today closed a follow-on financing round bringing total funds raised to date to $62M. This funding bolsters the company’s ability to commercialize its first-generation solid-state batteries and bring to market the world’s first multi-material multi-process additive manufacturing platform that will 3D print its second-generation SSBs and other active devices.