At Formnext 2022, in addition to an already impressive setup, Nexa3D released multiple company updates – which included an expansion of the company’s resin portfolio with the release of ceramic, flexible, and clear materials, and partnerships with both Xometry and Quickparts, as well as DyeMansion.

Three new resins

The three new photopolymer resins, tailored to address the growing demand for Nexa3D’s ultrafast industrial and desktop 3D printers, are available now. The new resins include xCERAMIC3280 (created in collaboration with material experts at BASF), a fast printing, rigid material with high heat deflection temperature and excellent tensile modulus, xMODEL17-Clear (created in collaboration with material experts at Henkel), a rigid and durable modeling material with enhanced clarity, perfect for prototyping applications that require fine feature details and high-quality translucent or transparent surface finishes, and xFLEX402, a flexible material with firmer shore 76A durometer, high elongation at break, and excellent tensile strength.

“Our expanding range of printers and materials presents a significant upgrade for traditional stereolithography and DLP users with its ultrafast printing speed, high volume precision, and broad range of performance materials that come at the most economical cost of ownership available on the market today,” said Kevin McAlea, Chief Operating Officer at Nexa3D.

Xometry partnership

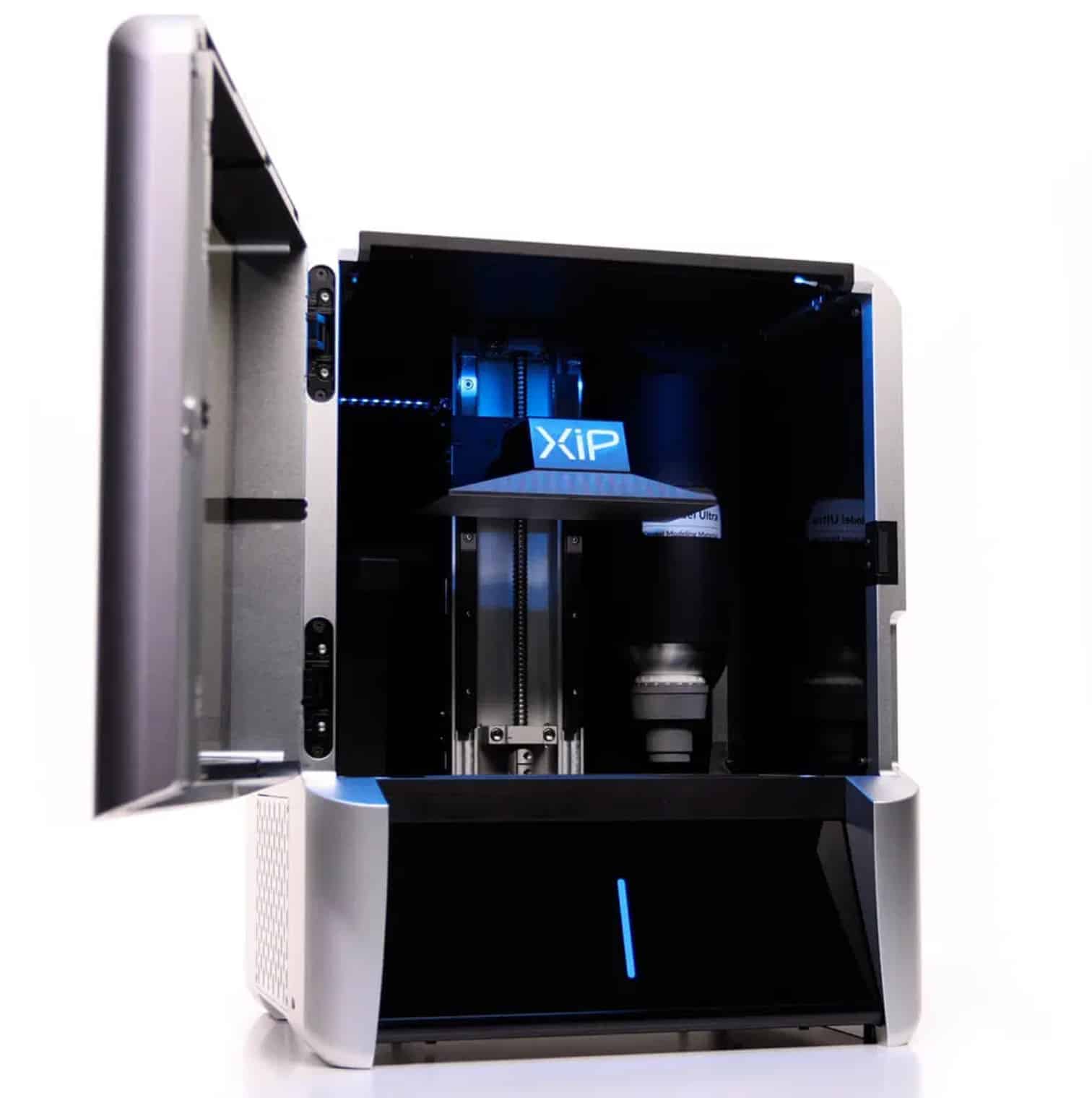

Nexa3D has made its patented Lubricant Sublayer Photo-curing (LSPc) 3D printing technology available through Xometry’s global digital marketplace, which connects enterprise buyers with manufacturing suppliers. The 3D printing service will be offered through Xometry’s global network of vetted suppliers that utilize both the industrial NXE-series and XiP desktop 3D printers.

“With over 400 Nexa3D printers currently in use worldwide, it’s great to know that our technology is going to reach an even wider audience through Xometry’s on-demand manufacturing network,” said Avi Reichental, Co-founder, and Chief Executive Officer of Nexa3D.

Quickparts partnership

Global on-demand manufacturing provider, Quickparts has added Nexa3D’s LSPc technology to its Express Service Offering, through the acquisition of the NXE-series and XiP desktop 3D printers, in addition to the previously-acquired QLS 820 powder bed production.

Manufacturing on Demand

Quickparts invested in Nexa3D’s thermoplastic serial production solution, the QLS 820, earlier this year, signing on as a foundational manufacturing partner in September 2022.

“We are excited to bring our customers the speed and quality they need to meet today’s market demands,” said Ziad Abou, CEO of Quickparts. “We’ve been working closely with Nexa3D and have validated its industrial and desktop 3D printers, both utilizing the ultrafast LSPc 3D printing technology to help meet our customers’ needs for quicker turn-times and uncompromised part quality.”

DyeMansion partnership

Finally, Nexa3D and DyeMansion have entered a strategic partnership to automate the end-to-end additive manufacturing workflow with the integration of the QLS 820 powder bed fusion platform (which has a throughput of 8 liters per hour at 20% packing density), with DyeMansion’s Print-to-Product workflow – an automated 3-step post-processing solution for complete end-to-end serial manufacturing workflow.

The partnership will also leverage Siemens PLC integration, and NexaX software, to further automate and integrate high-throughput production for true lights-out manufacturing.

This strategic partnership will help users access best-in-class automation capabilities to reduce manufacturing costs and deliver accessibility and transparency at every stage of the process so they can easily manage productivity and product quality. Users will be able to integrate DyeMansion’s suite of post-processing equipment with NexaX and the QLS Command Center for insight into real-time job monitoring as well as long-term performance of their equipment all from one dashboard.

“Nexa3D is driving innovation to digitize the supply chain sustainably by making the world’s fastest polymer 3D printers affordable for professionals and businesses of all sizes,” said Kevin McAlea, Chief Operating Officer, Nexa3D. “It’s only natural that we would partner with DyeMansion, a leading provider of automated post-processing solutions for powder bed fusion, to ensure that our industrial customers can leverage high-throughput manufacturing capabilities from end-to-end as well as reduce their total cost of operation.”

You might also like:

Gelomics and Rousselot partner on 3D cell culture kits: GelMA is a well-known biomaterial with tuneability and bioactivity that is used in a wide range of tissue engineering, 3D bioprinting and 3D cell culture applications. Rousselot’s X-Pure GelMA is ultra-pure (<10 Endotoxin Units (EU)/g), and the first GelMA to be produced under GMP conditions. The new LunaGel X-Pure gelatin product series will be available as ready-to-use kits in low and high-stiffness formulations, providing the world’s first premium, ultra-pure GelMA in an easy-to-use format.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment