- DLP 3D Printed Chameleon Model with Ultra-Detail

- Full-Color and SLA 3D Printed Board Game Miniatures Comparison

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 5 workdays

Gallery

About Project

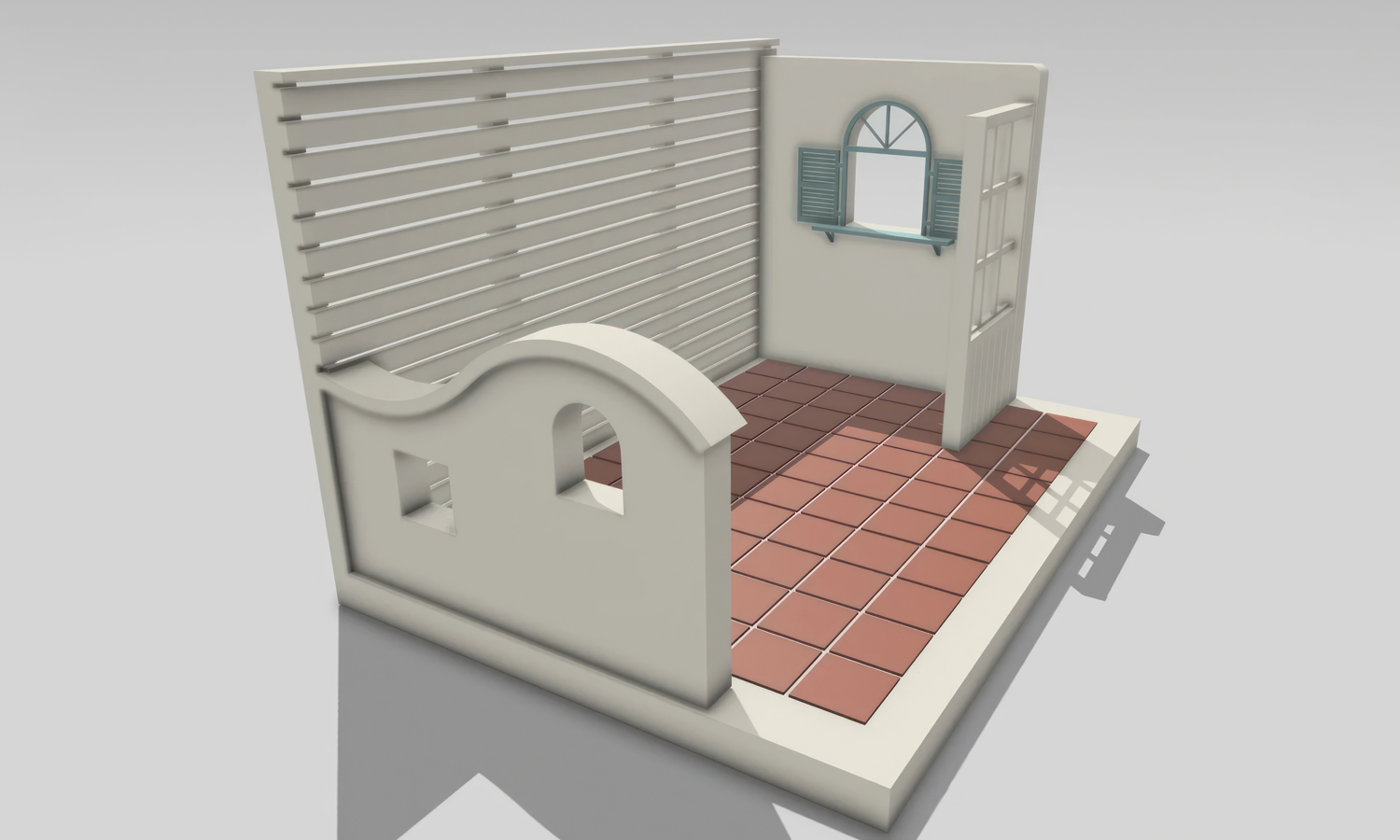

This charming Mediterranean-style miniature patio began as a digital concept, designed to capture the warmth of sunlit walls, rustic terracotta tiles, and the breeze through open shutters. The creator envisioned a cozy, seaside atmosphere-complete with a curved courtyard wall, grid-paned door, and wood-slatted backdrop reminiscent of Greek island cottages.

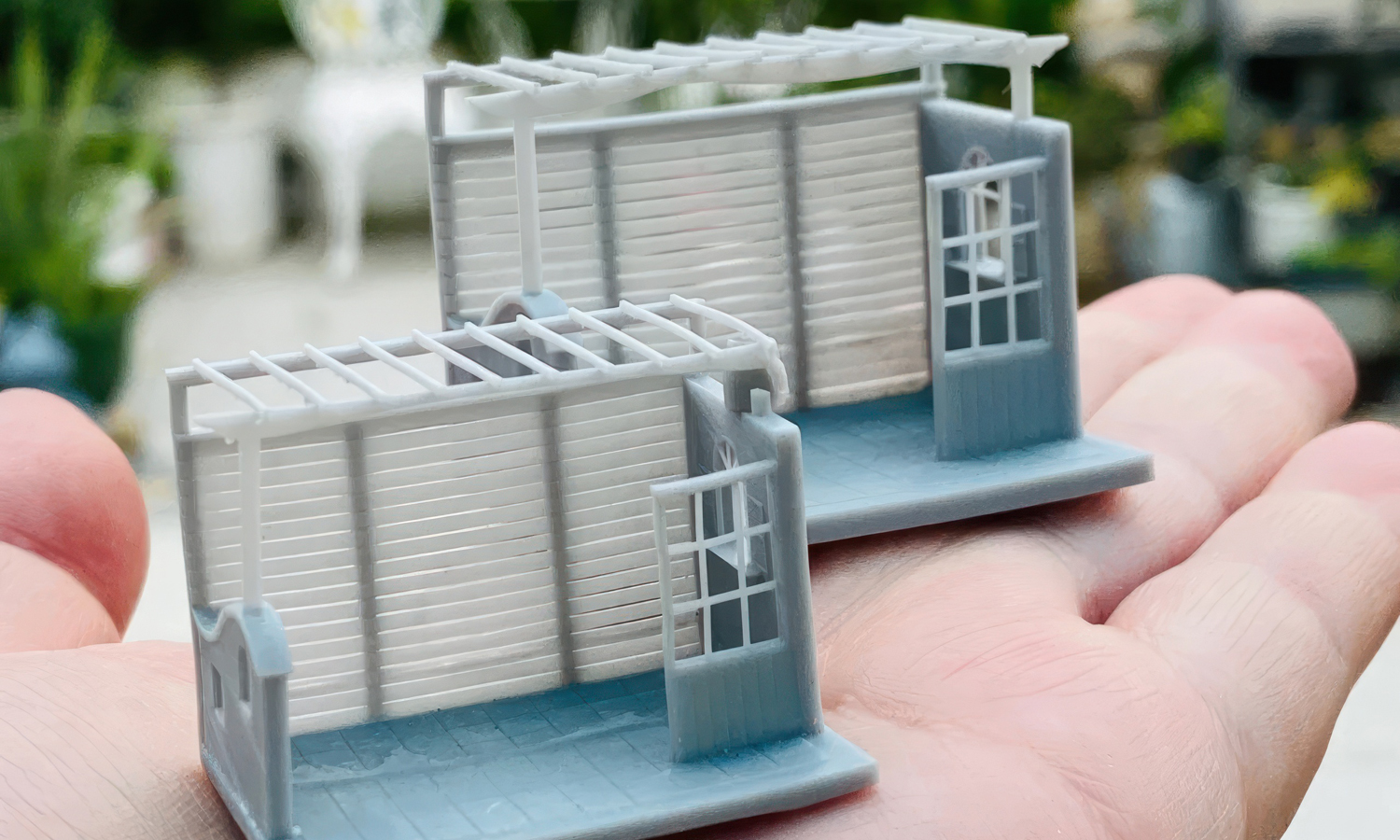

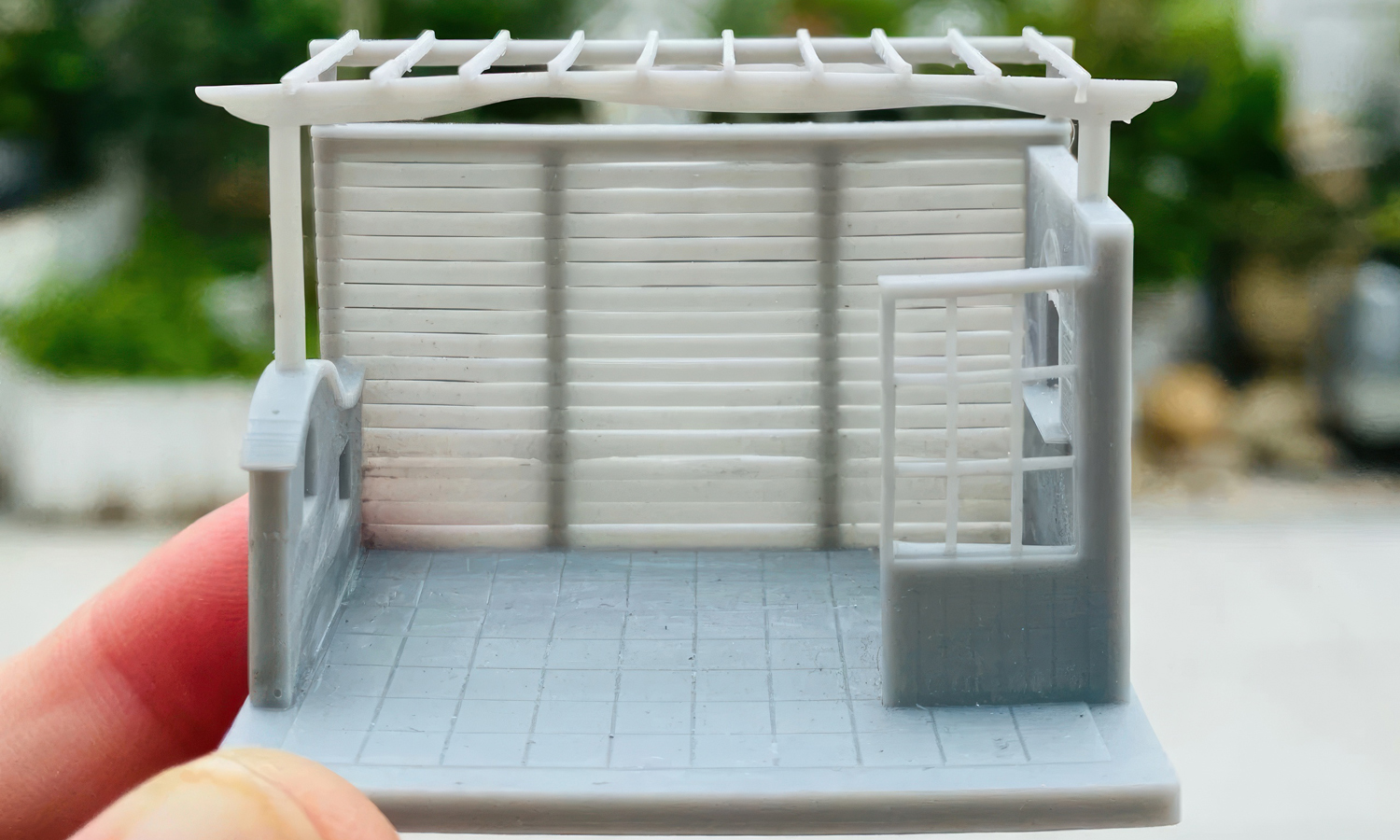

The model was first sculpted digitally in Shapr3D, then refined for printing. Once the design was finalized, it was transformed from a 3D render into a tangible scene through high-precision SLA resin printing. The printed model displayed crisp edges, smooth surfaces, and well-defined textures-perfect for miniature painting and surface treatment.

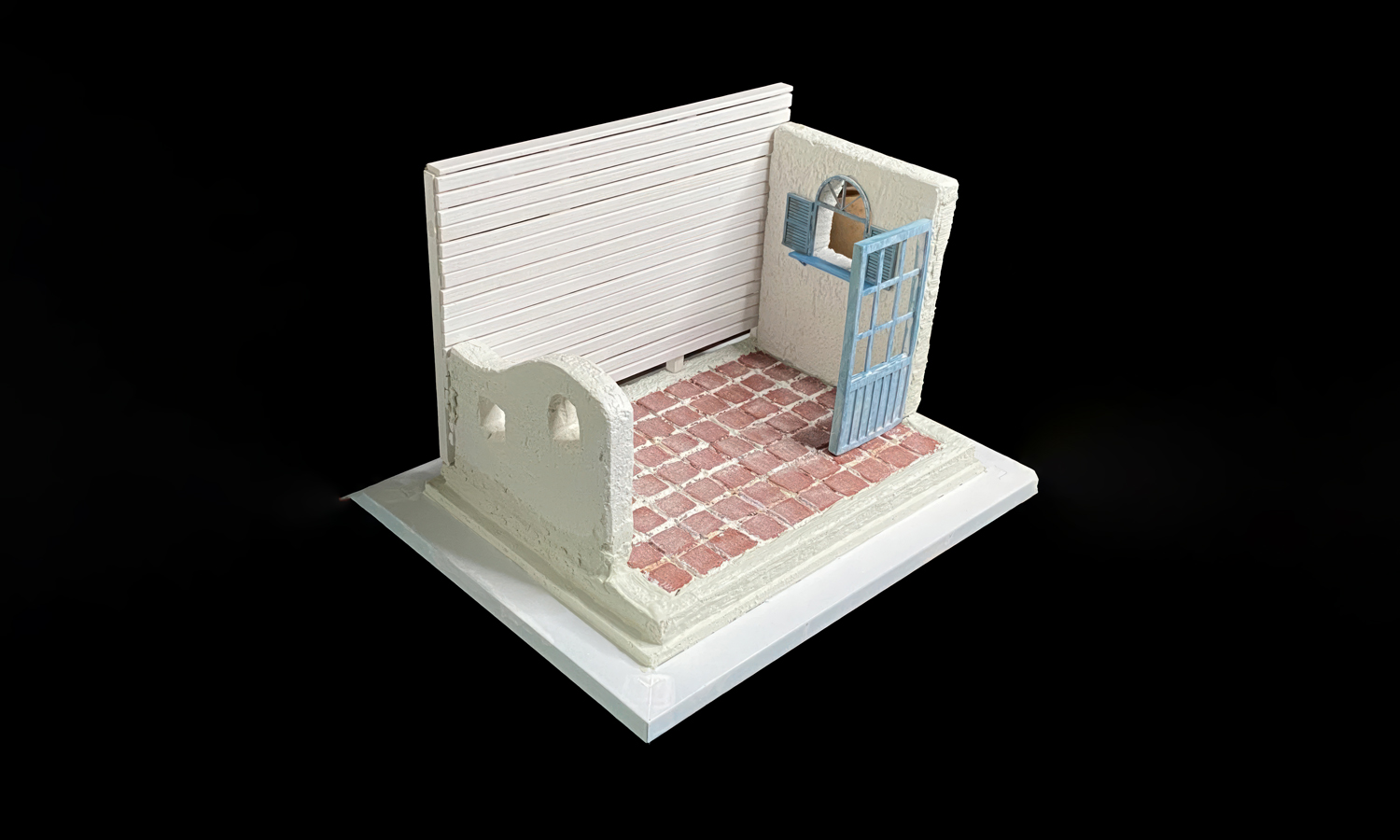

After printing, the model was carefully cleaned, assembled, and hand-finished with layered acrylic paints. The walls were textured to mimic stucco plaster, the shutters and door painted in light turquoise, and the floor tiles coated in terracotta tones to bring out a realistic aged feel. The final result bridges digital design and handcrafted detail, showing how 3D printing empowers creators to bring architectural dreams to life on a small scale.

FacFox offers the perfect platform for such creative transformations. With professional-grade full-color and resin 3D printing services, we help artists, designers, and miniature makers produce models that faithfully capture both structure and texture. Whether you’re visualizing a game environment, film set, or collectible diorama, FacFox can turn your virtual design into a display-ready masterpiece.

Solution

- Step 1: References were gathered. Architectural photos and proportions for a Mediterranean patio were collected and translated into a scale brief.

- Step 2: CAD geometry was modeled. The walls, slatted backdrop, tiled floor, curved parapet, window, and door were created and parametric dimensions were set in Shapr3D/Nomad.

- Step 3: Printability was prepared. Overhangs were checked, wall thicknesses were unified, and delicate slats were slightly thickened to meet minimum feature constraints.

- Step 4: Files were exported. Water-tight STLs were exported by component (base, door, window/shutters, wall set) to enable clean printing and painting.

- Step 5: Parts were oriented and supported. Each STL was oriented to minimize layer lines on show faces; light-to-medium tree supports were generated with denser tips on slats and muntins.

- Step 6: Slicing was completed. Layer height (Ōēł0.05-0.1 mm), anti-aliasing, lift speeds, and UV exposure were tuned; build files were saved in Chitu-compatible format.

- Step 7: SLA printing was performed. Grey photopolymer resin was used and parts were printed on an MSLA machine with a clean FEP and leveled build plate.

- Step 8: Parts were washed. Fresh IPA baths were used to remove uncured resin; compressed air and soft brushes were applied to clear the window grids and slat gaps.

- Step 9: Post-curing was carried out. Parts were UV-cured to full hardness while warpage was prevented with flat supports and intermittent cooling.

- Step 10: Supports were removed. Nippers and a scalpel were used to clip tips at contact points; remaining nubs were trimmed.

- Step 11: Surfaces were refined. Show faces were sanded from 600ŌåÆ1000 grit; tile edges were lightly chamfered; pinholes were filled with putty and re-sanded.

- Step 12: Assembly was conducted. The base, walls, and parapet were dry-fitted, then bonded with CA glue; the door and shutters were left separable for painting.

- Step 13: Priming and texture were applied. A neutral primer was sprayed; acrylic paste was stippled on the wall faces to simulate stucco; grout lines on the floor were defined.

- Step 14: Painting was completed. Terracotta tones were airbrushed on tiles; stucco was finished in warm off-white; the door and shutters were painted pastel turquoise with panel-line accents.

- Step 15: Weathering and sealing were finished. Dry-brushing and washes were applied for depth; a matte clear coat was sprayed for protection and a consistent scale sheen.