- FDM 3D Printed Pagoda of Fogong Temple Scaled-down Model

- Mold Casting Polyurethane Tapered Drain Plug

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

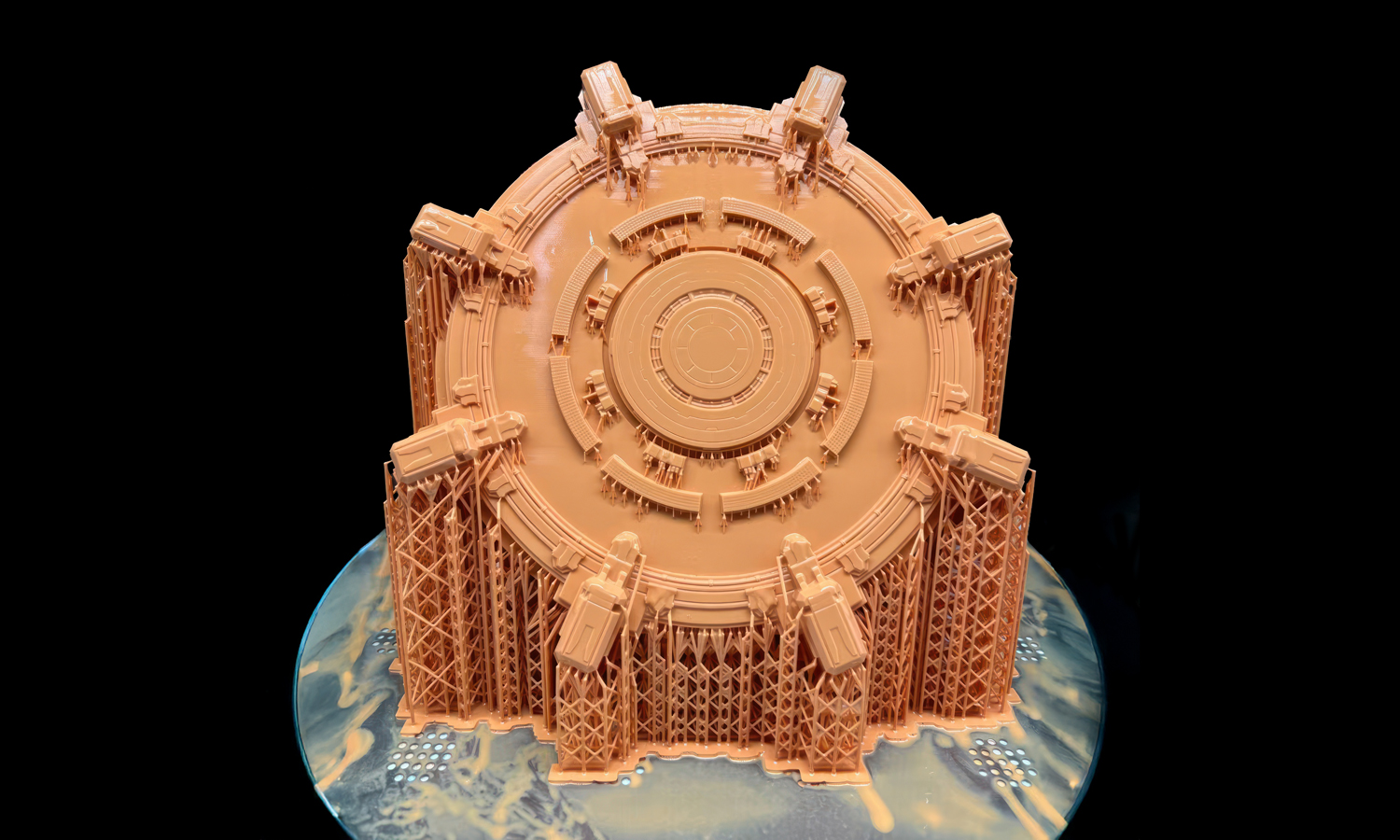

Get ready to elevate your sci-fi dioramas and model displays with our latest creation: the LCD 3D Printed Resin Round Missile Silo Terrain Space Model. This meticulously crafted piece brings the futuristic and mechanical elegance of a high-tech missile silo right to your desktop.

Intricate Design and Details

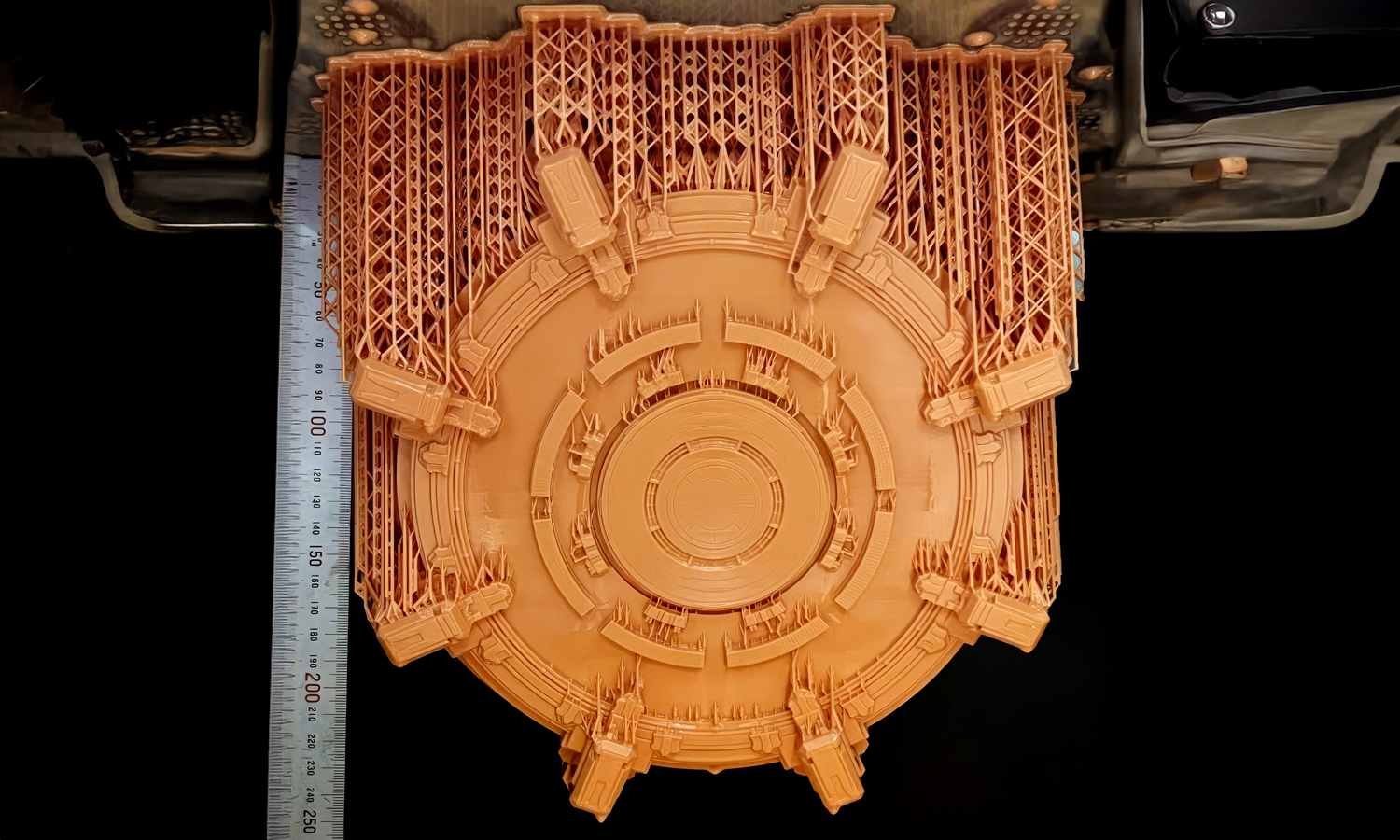

This model features a vibrant orange, circular design with a diameter of approximately 25 centimeters. The intricate engravings, symmetrical patterns, and detailed structures give it an authentic and realistic look, perfect for any sci-fi enthusiast. The central area is adorned with fine engravings, while the surrounding structures and protrusions add depth and a touch of futuristic architecture.

High-Quality Resin Material

Crafted using high-quality resin, this model offers durability and precision. The stepped design from the smaller diameter top section to the larger base highlights the model’s hierarchical structure, making it an excellent addition to any collection or diorama.

Why Choose LCD 3D Printing?

LCD 3D printing technology allows for incredibly detailed and delicate models. The precision of the process ensures that every fine line and pattern is accurately reproduced, resulting in a high-quality final product.

FacFox’s LCD 3D Printing Service

If you’re looking to create your own intricate and delicate models, we highly recommend FacFox’s LCD 3D printing service. FacFox specializes in delivering high-resolution prints with exceptional detail, making them the perfect choice for all your 3D printing needs. Their expertise and commitment to quality ensure that your models will come out perfectly every time.

Explore the possibilities with FacFox and bring your creative visions to life! ¤ī¤

Solution

- Step 1: Digital Model Design. A detailed 3D model of the missile silo terrain was designed using CAD (Computer-Aided Design) software.

- Step 2: File Preparation. The 3D model file was converted into a format suitable for LCD 3D printing, typically an STL or OBJ file. Necessary supports for overhanging structures were added virtually.

- Step 3: Resin Preparation. Liquid resin, chosen for its properties and color, was poured into the vat of the LCD 3D printer.

- Step 4: Printing Process. The prepared digital file was loaded into the printer. Layer by layer, the model was built by selectively curing the liquid resin with UV light projected from an LCD screen. The build platform was gradually moved upwards to create the 3D object.

- Step 5: Post-Processing. The printed model was removed from the build platform. Excess resin was carefully washed away using a suitable solvent. Support structures were detached from the model. The model was further cured under UV light to ensure complete hardening.

- Step 6: Finishing Touches (Optional). Depending on the desired finish, the model may have been sanded, primed, and painted.