- LPBF 3D Printed SS316L 3mm Medical Forceps Tip

- SLA 3D Printed Large Grid Structure with Interlocking Bars

Gallery

About Project

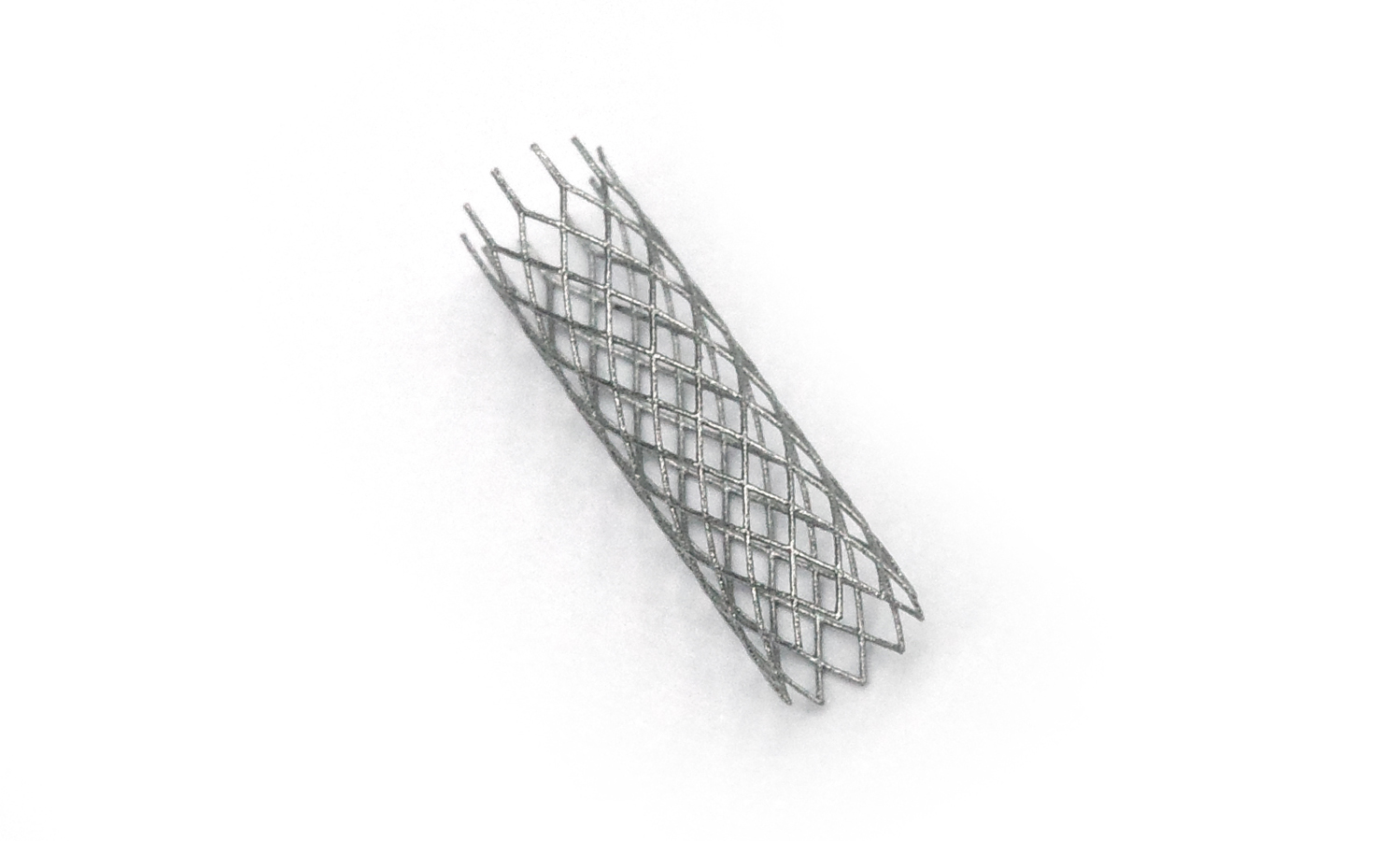

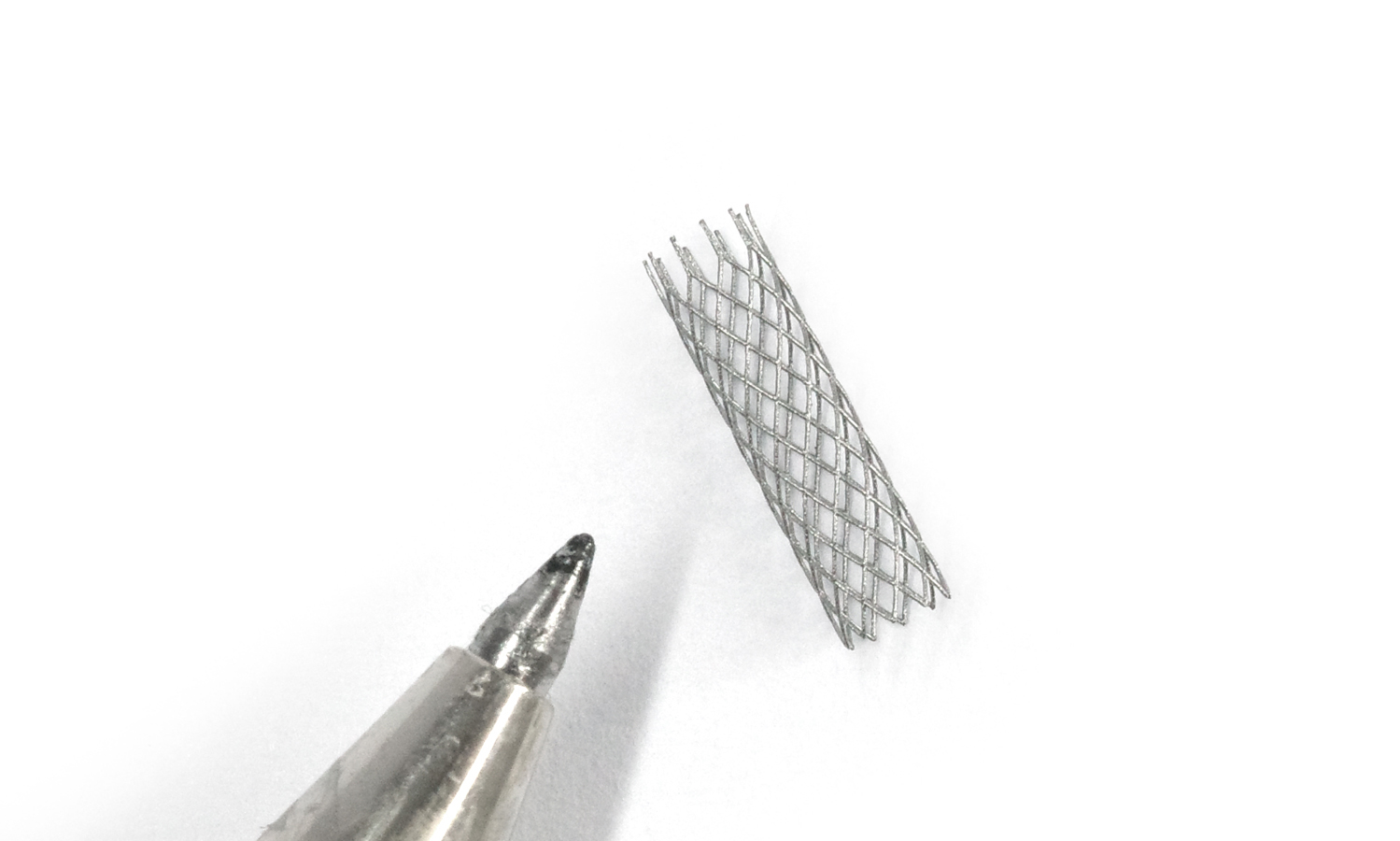

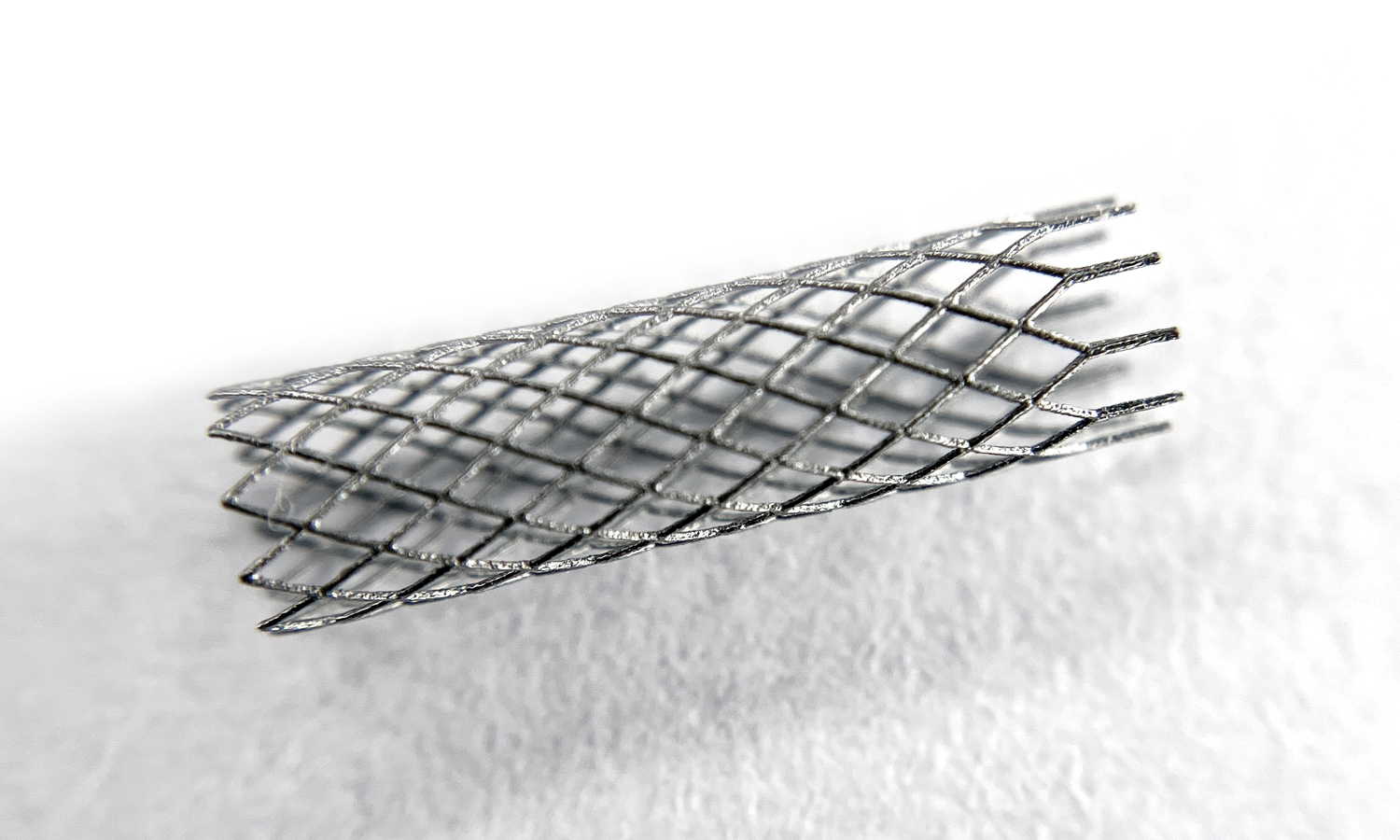

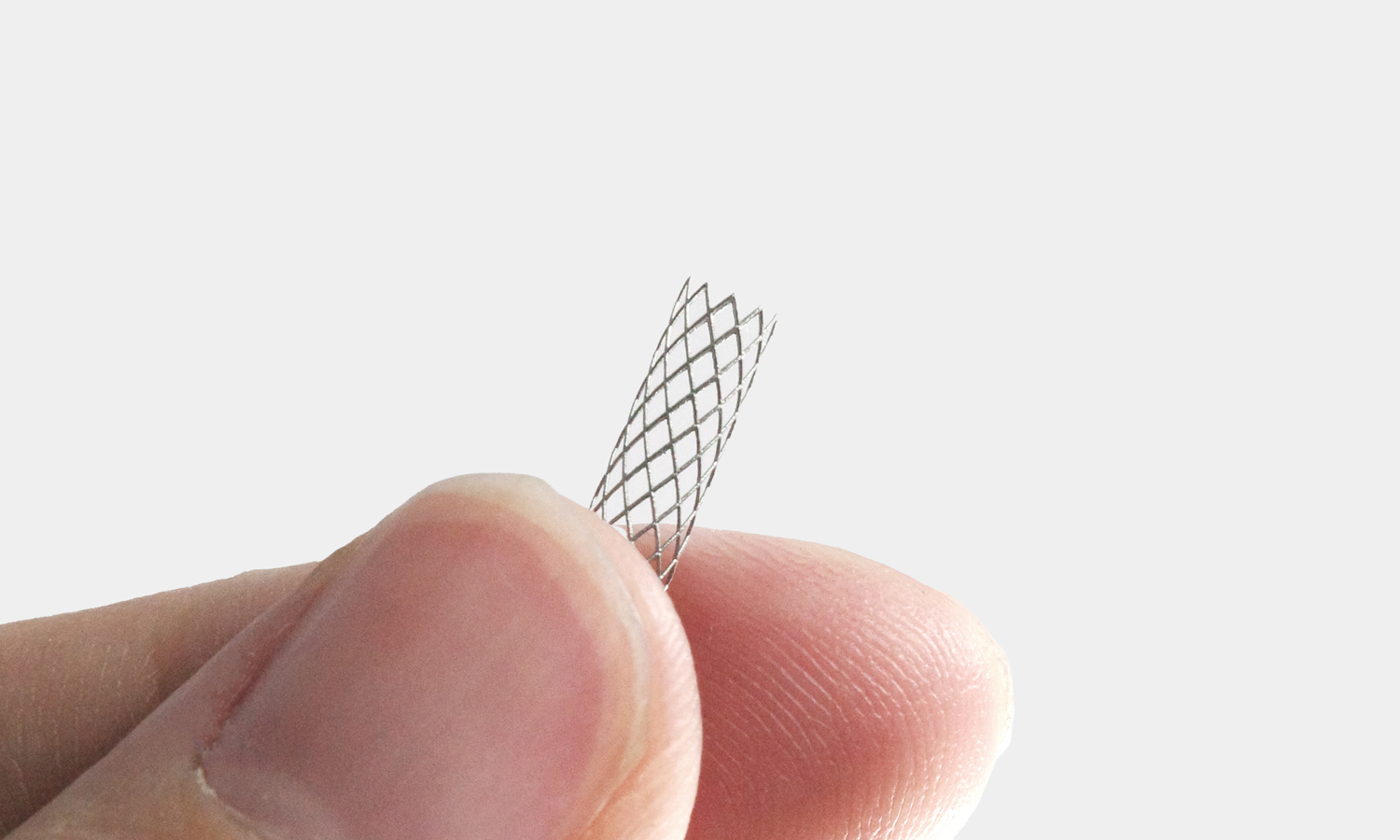

We are excited to announce the successful development of a 3D-printed 12mm SS316L coronary stent using Laser Powder Bed Fusion (LPBF) technology. This innovative medical device holds immense potential in improving patient outcomes and revolutionizing cardiovascular care.

The Importance of Coronary Stents

Coronary stents are essential tools in interventional cardiology. They are used to keep coronary arteries open after they have been widened through angioplasty, ensuring adequate blood flow to the heart. Traditional stents are often limited in their design and customization options.

The Advantages of 3D Printed Stents

Our 3D-printed coronary stent offers several key advantages:

- Complex Geometries: LPBF allows for the creation of intricate and customized stent designs that can better address specific patient needs and anatomical variations.

- Improved Biocompatibility: The use of biocompatible materials like SS316L ensures minimal tissue response and reduces the risk of adverse events.

- Excellent precision and resolution:┬ĀThe minimum wall thickness is 30 ╬╝m and the overhang structure is 50 ╬╝m-long.

- Enhanced Strength and Durability: 3D-printed stents can be designed with optimized mechanical properties to provide long-lasting support to the artery walls.

- Reduced Manufacturing Time: Additive manufacturing eliminates the need for traditional tooling and assembly processes, leading to faster production times and reduced costs.

Expanding Our Capabilities

Beyond SS316L, we are also capable of printing coronary stents using other biocompatible metals such as cobalt-chromium alloy, Ni-base alloy, and Ti-base alloy. These materials offer varying properties and can be selected based on specific clinical requirements.

FacFox: Your Partner in Additive Manufacturing

At FacFox, we are committed to providing cutting-edge 3D printing solutions for the medical and healthcare industries. Our LPBF technology enables us to produce high-quality, precision-engineered stents with exceptional accuracy and surface finish.

If you are interested in learning more about our 3D printing services or exploring the possibilities of customized coronary stents, please contact us today. We are dedicated to partnering with healthcare professionals to improve patient outcomes and advance medical technology.

Solution

- Step 1: Design Creation.┬ĀThe design of the stent was created using computer-aided design (CAD) software. The intricate mesh structure was carefully modeled to ensure it could expand and support the artery walls.

- Step 2: File Preparation.┬ĀThe CAD file was converted into a format suitable for 3D printing, typically an STL file. This file was then sliced into thin layers to generate the G-code, which directed the 3D printer.

- Step 3: Powder Preparation.┬ĀStainless steel 316L (SS316L) powder was prepared and loaded into the LPBF 3D printer. The powder was chosen for its biocompatibility and mechanical properties.

- Step 4: Build Plate Setup.┬ĀThe build plate was cleaned and coated with a thin layer of the SS316L powder. This ensured proper adhesion of the first layer of the stent.

- Step 5: Laser Scanning.┬ĀThe laser beam was directed onto the powder bed, selectively melting the powder according to the design. This process was repeated layer by layer, with each layer being fused to the previous one.

- Step 6: Layer Recoating.┬ĀAfter each layer was fused, the build plate was lowered, and a new layer of powder was spread over the previous layer. This process continued until the entire stent was built.

- Step 7: Cooling.┬ĀOnce the printing was completed, the build chamber was allowed to cool down to prevent thermal stresses and warping of the stent.

- Step 8: Post-Processing.┬ĀThe stent was removed from the build plate and underwent post-processing steps, including heat treatment to relieve residual stresses and improve mechanical properties.

- Step 9: Surface Finishing.┬ĀThe stent was polished and cleaned to remove any loose powder and achieve the desired surface finish. This step ensured the stent’s biocompatibility and smoothness.

- Step 10: Quality Inspection.┬ĀThe stent was inspected for dimensional accuracy and structural integrity using techniques such as microscopy and non-destructive testing. Any defects were identified and corrected.

- Step 11: Sterilization.┬ĀThe final stent was sterilized to ensure it was safe for medical use. Common sterilization methods included autoclaving or gamma irradiation.

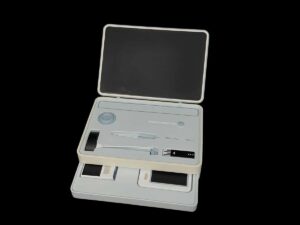

- Step 12: Packaging.┬ĀThe sterilized stent was packaged in a sterile environment to maintain its cleanliness and readiness for surgical procedures.