- WJP 3D Printed Full-color Figurine Generated by ChatGPT

- SLS 3D Printed Nylon Threaded Two Hole Pins Set for Pipe Fitting

Material Metal

Quantity 2 pcs

Price Range $1-100

Lead Time 3 workdays

Gallery

About Project

3D printing, especially Selective Laser Melting (SLM), has revolutionized manufacturing, allowing for complex geometries and rapid prototyping. However, a common characteristic of SLM 3D printed metal parts is their relatively rough surface finish, a direct result of the layer-by-layer additive process. This often necessitates post-processing to achieve desired surface qualities for functional or aesthetic purposes.

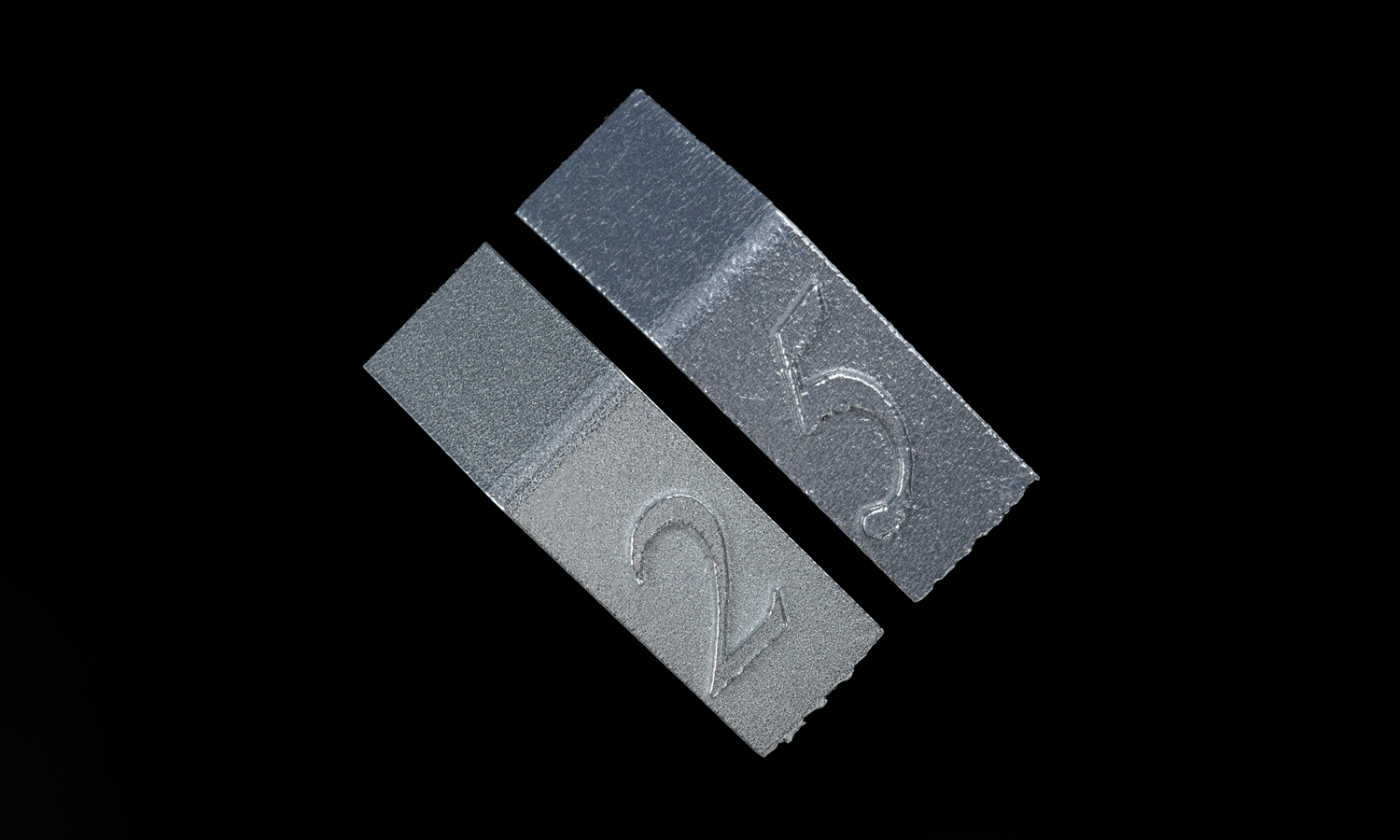

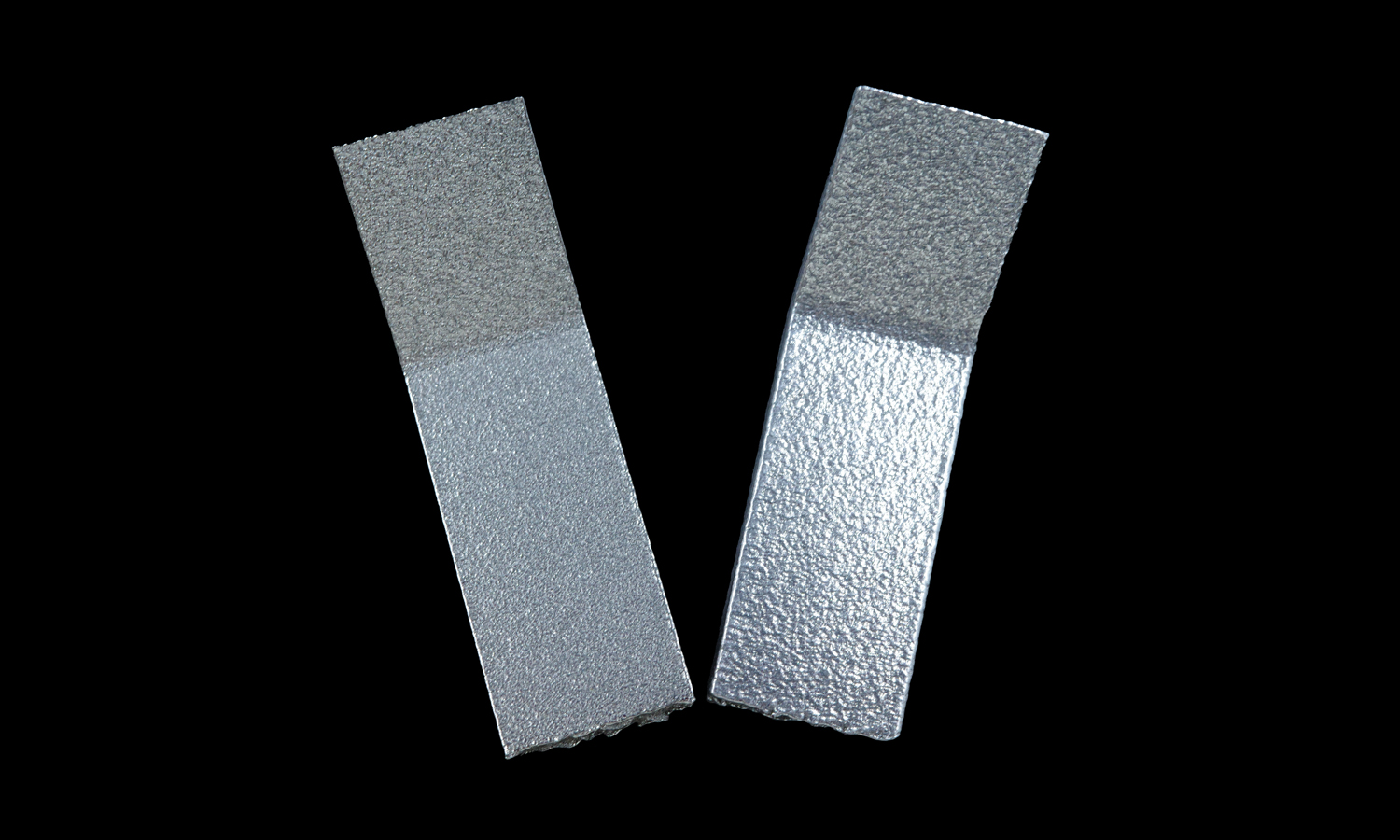

We recently conducted a test on two SLM 3D printed metal parts using a Magnetic Abrasive Finishing (MAF) method. The two samples, shown above, demonstrate the results of this technique. The sample marked “5” was printed using AlSi10Mg, a common aluminum alloy for additive manufacturing, while the sample marked “2” was printed with SS316L (Stainless Steel 316L), known for its corrosion resistance and strength.

Understanding Magnetic Abrasive Finishing

Magnetic Abrasive Finishing is a non-traditional finishing process that utilizes a magnetic field to control abrasive particles. These particles, typically a mixture of magnetic and non-magnetic abrasives, form a flexible “magnetic abrasive brush” that conforms to the part’s contours. As the magnetic field moves or the part rotates, the abrasive particles rub against the surface, removing material and reducing surface roughness. This method is particularly adept at reaching intricate geometries and internal features that are challenging for conventional polishing techniques.

Surface Quality Assessment

Following the magnetic abrasive finishing, both the AlSi10Mg and SS316L samples showed a clear improvement in surface quality compared to their as-printed state. The characteristic layered texture, prominent in raw SLM parts, was visibly reduced, resulting in a more uniform and refined appearance. The samples exhibited a smoother feel, and the reflectivity increased slightly, indicative of a finer finish.

However, it’s important to set realistic expectations. While magnetic abrasive finishing significantly enhances the surface, the inherent roughness of 3D printed metal parts means the ultimate smoothness achievable is limited. The finished outcome, though improved, cannot rival the mirror-like finish or precision typically achieved with traditional subtractive manufacturing methods like CNC machining. This is due to the fundamental differences in material removal mechanisms and the initial surface topography. MAF is an excellent method for improving 3D printed surfaces, but it’s not a magic bullet for achieving ultra-high precision finishes on inherently rough substrates.

Unlock the Potential of Your Designs with FacFox

At FacFox, we understand the nuances of 3D printing and post-processing. We offer comprehensive metal 3D printing services utilizing advanced SLM technology with a wide range of materials, including AlSi10Mg and SS316L. Beyond printing, our expertise extends to various post-processing techniques like Magnetic Abrasive Finishing, designed to optimize your parts for their intended application. For clients seeking even higher levels of surface finish, we also offer a range of additional post-processing options, including precision CNC machining, sandblasting, and meticulous hand polishing. Whether you need functional prototypes, complex components, or aesthetically pleasing parts, FacFox provides end-to-end solutions, delivering high-quality metal prints with the right finish for your needs. Explore the possibilities with FacFox and bring your designs to life!

Solution

- Step 1: The selected metal powder (AlSi10Mg or SS316L) was carefully loaded into the powder bed of the Selective Laser Melting (SLM) 3D printer.

- Step 2: The parts were printed layer by layer. A high-powered laser selectively melted and fused the metal powder particles according to the digital CAD model, building the geometry from the bottom up.

- Step 3: Once the printing process was complete and the build chamber cooled, the printed parts, along with any necessary support structures, were carefully removed from the build platform.

- Step 4: Post-printing, all temporary support structures, which prevented deformation during the printing process, were meticulously detached from the main printed components.

- Step 5: Magnetic abrasive finishing was then applied. The parts were exposed to a rotating magnetic field which manipulated a mixture of magnetic and abrasive particles. These particles gently abraded the surfaces, improving roughness and finish.

- Step 6: Finally, the finished parts were thoroughly inspected for surface quality, dimensional accuracy, and overall integrity to ensure they met the required specifications.