Gallery

About Project

In this case, our client was a custom manufacturer of machines for auto parts manufacturing machines. They specialized in auto parts manufacturing machines, machinery for making truck and bus mufflers, automated auto machine tools, fixtures and testing equipment for automotive exhaust systems, automotive chassis component manufacturers, and auto parts manufacturing. Based in China, their design and auto parts manufacturing machines provide complete end-to-end customer solutions from concept development through after-sales service including training, maintenance, and re-tooling.

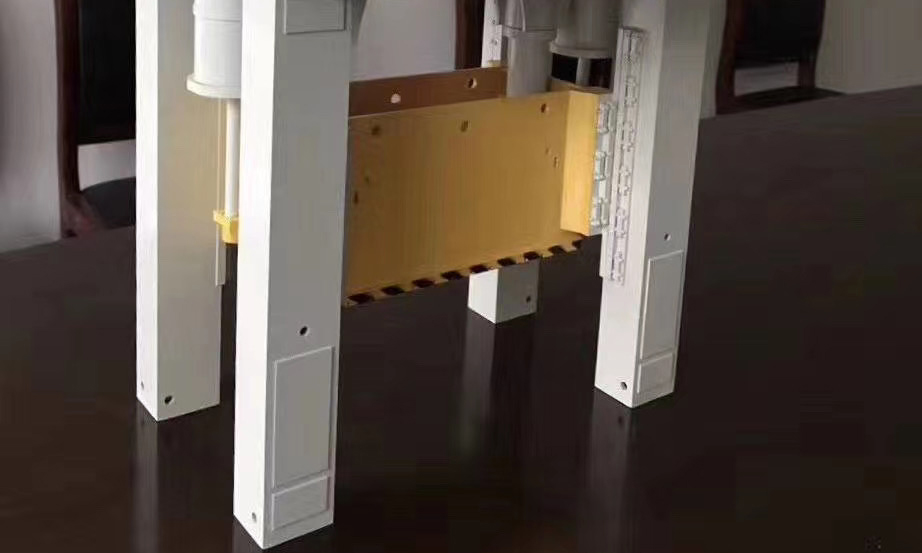

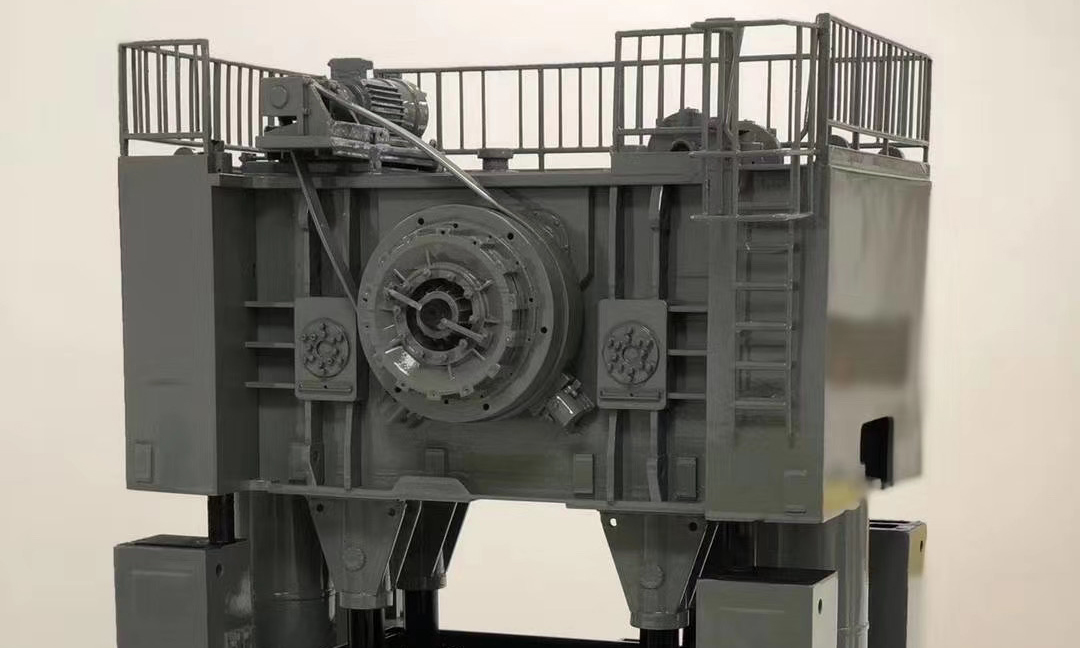

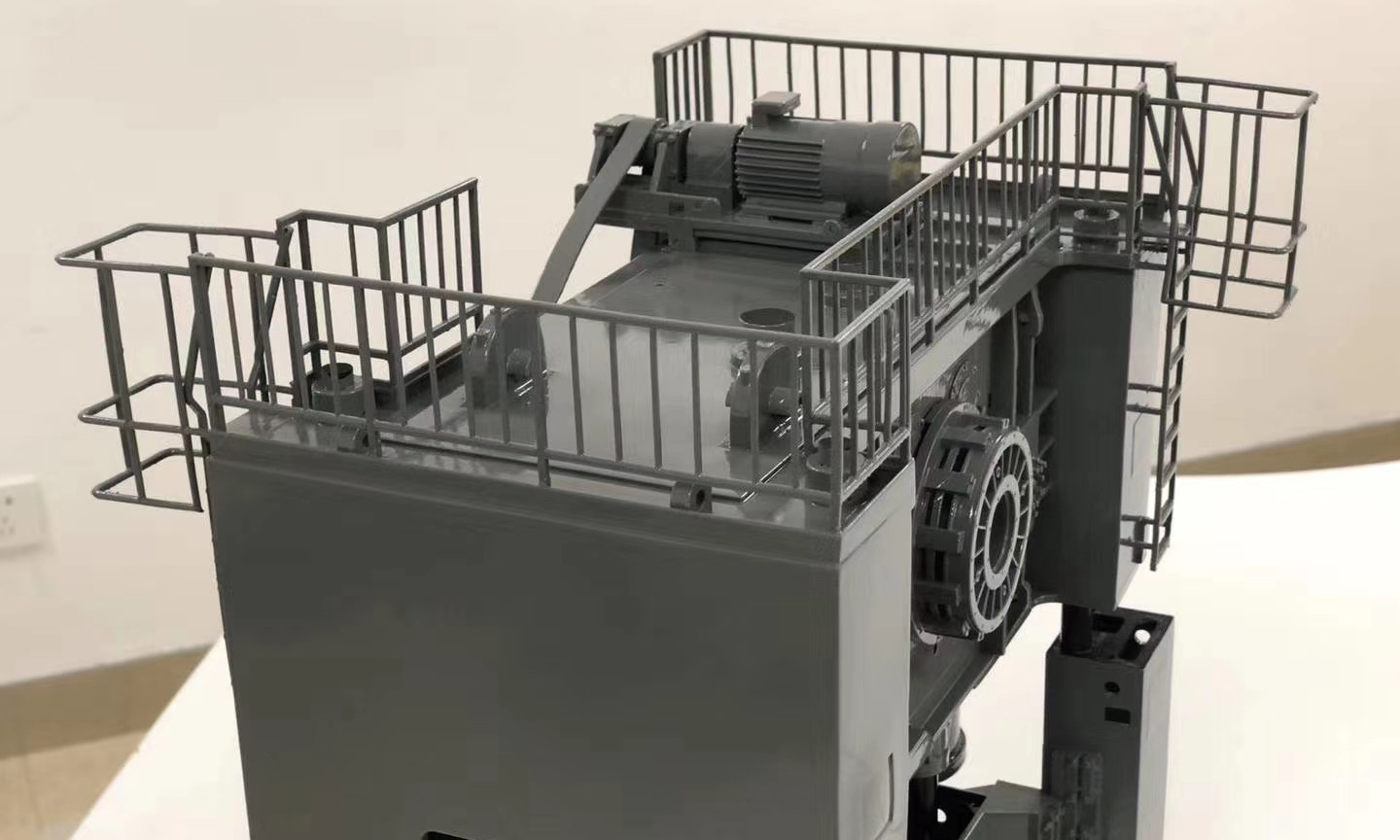

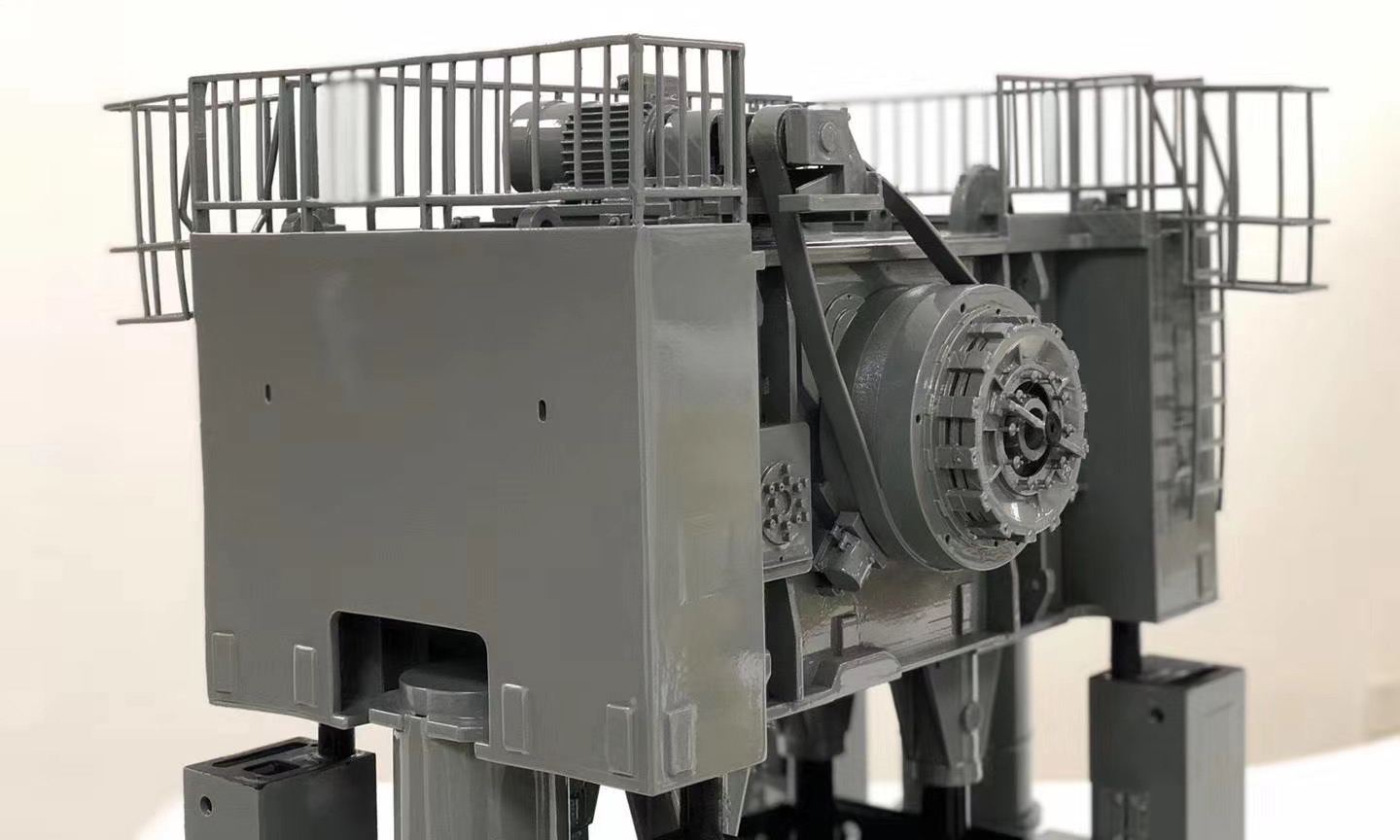

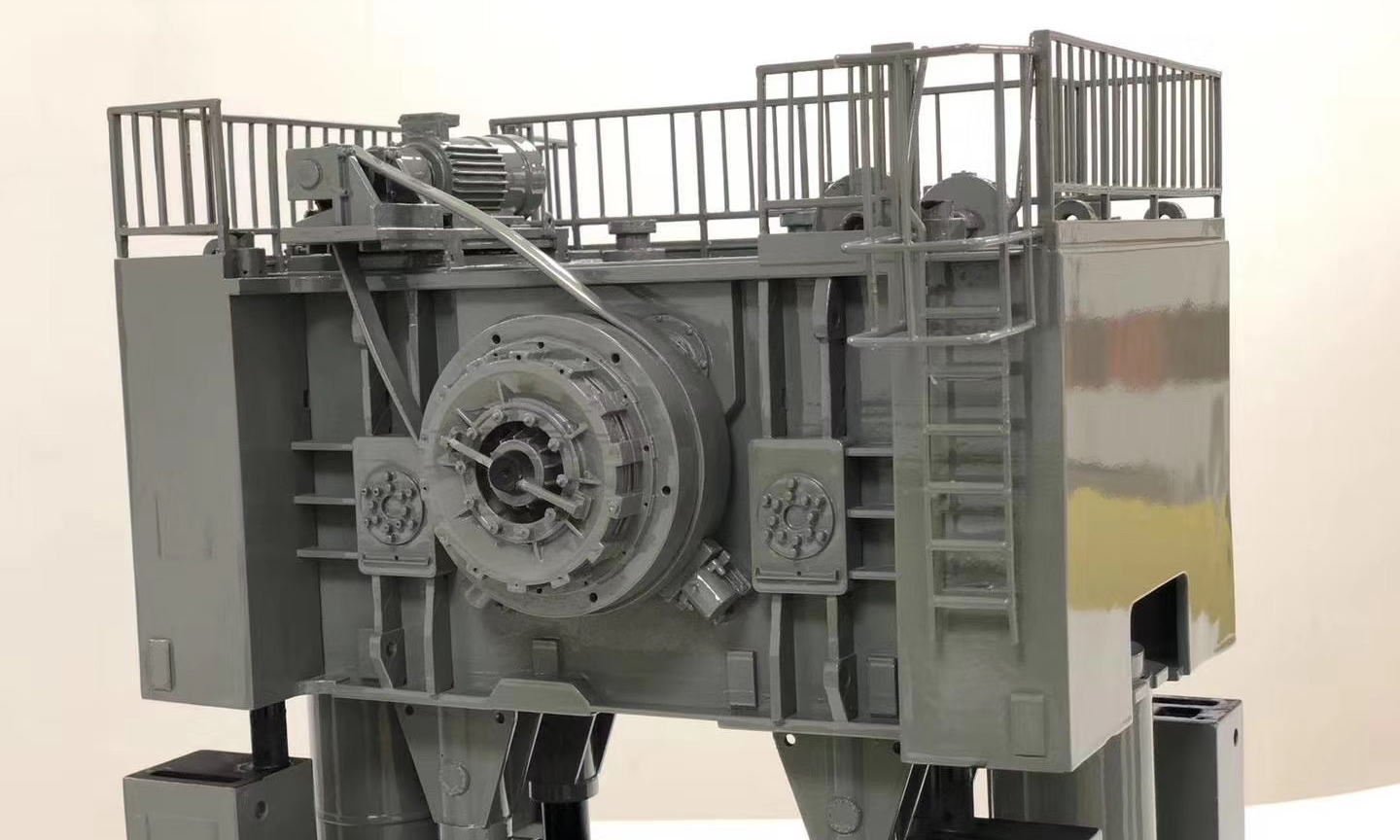

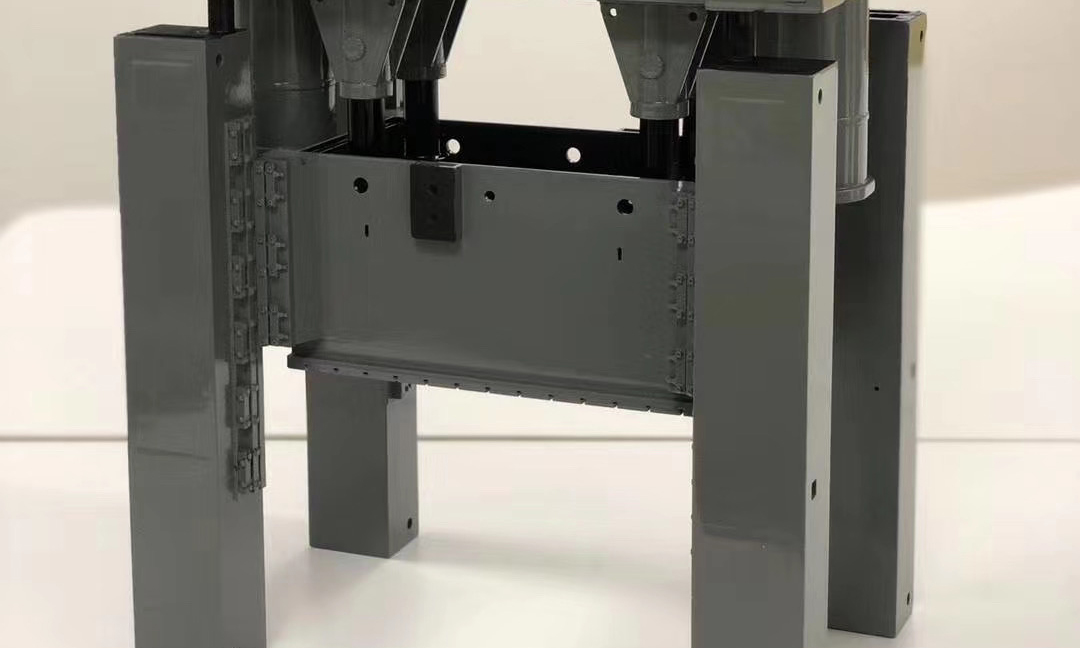

An auto parts company just ordered a giant machine from our client. After both sides were consent with the blueprint of the customized machine, we were committed to print the prototype for appearance verification. The machine was a bit complicated so we recommended using SLA 3D printing technology. As required by our client, the model was printed in one piece and then painted with different colors manually.

Solution

- Step 1: Double-check the CAD model to find if there any improper design would cause mistakes during 3D printing.

- Step 2: Add the supporting structure, slice the model with software, and then import it into the SLA 3D printer.

- Step 3: 3D print the model in one piece with SLA Black Tough Resin.

- Step 4: Remove excess material, wash the model to clean away the supports, and then post-cure it with UV.

- Step 5: Spray with grey paint for the convenience of checking all the uneven parts.

- Step 6: Use scraper, sandblaster, and putties to make the surface smooth and even.

- Step 7: Paint the model as requests by hand.