- SLA 3D Printed Frank from The Return of the Living Dead

- 3D Printed Stormtrooper Helmet with SLA Castable Resin

Material Metal

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

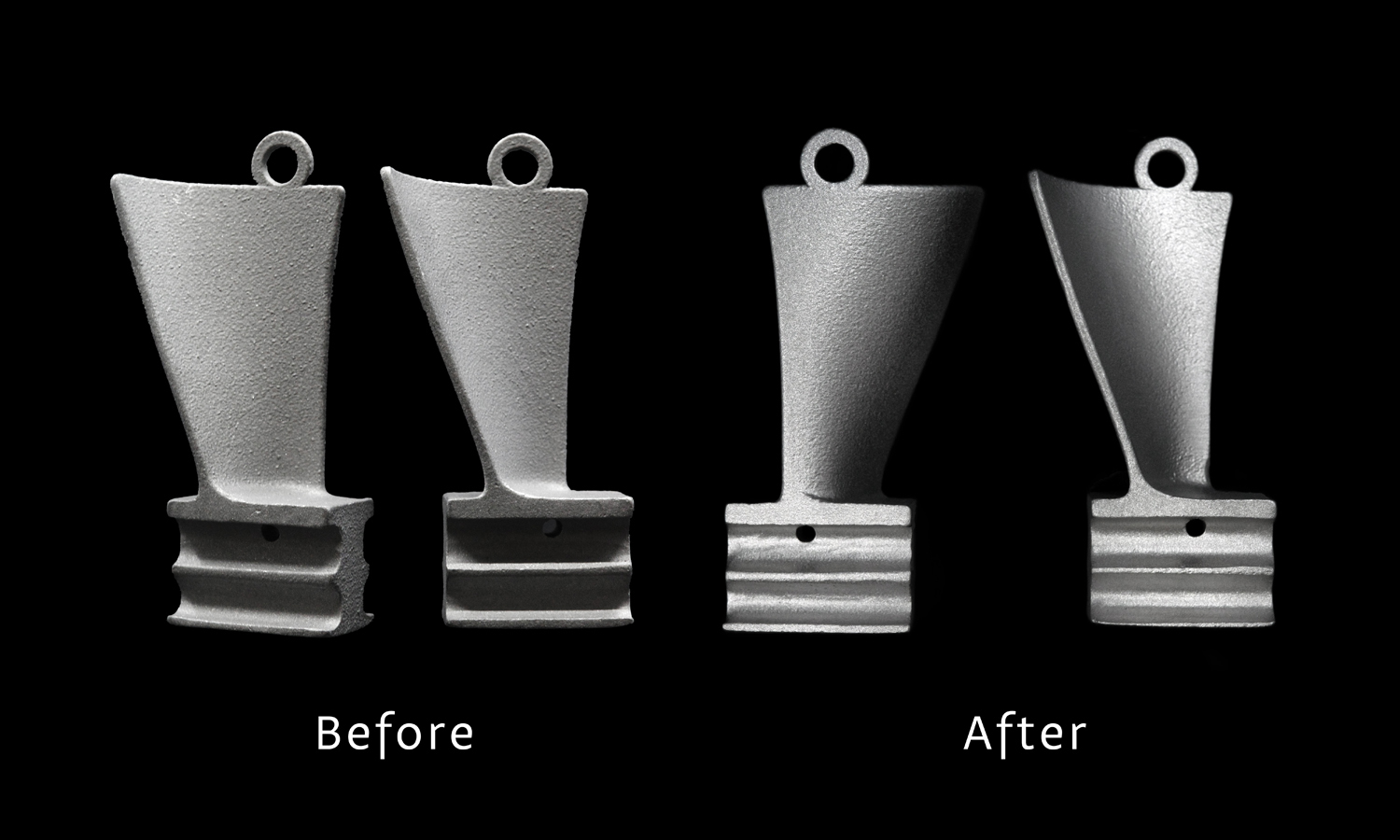

These custom corporate gifts, printed using Selective Laser Melting (SLM), provide a clear look at the transition from “raw” metal printing to a finished state. The sandblasting process has been applied to bridge the gap between industrial production and a gift-quality aesthetic.

How Sandblasting Improved the Quality

The “After” version shows a clear step up from the raw state in several key areas:

-

Reduced Metallic Glare: The raw SLM parts often have inconsistent “glitter” or hot spots where the laser fully melted the powder. Sandblasting creates a diffuse, matte surface that looks more intentional and professional.

-

Texture Uniformity: It has successfully blended the minor surface variations and “fuzziness” typical of the SLM powder-bed process, giving the aluminum a more cohesive, solid feel.

-

Highlighting Geometry: By creating a uniform matte finish, the light catches the curves of the blade more elegantly, making the aerodynamic design “pop” more than it does in the raw, grainy version.

Honest Evaluation: Remaining Imperfections

While the sandblasting has improved the parts, they are not “flawless.” An honest inspection reveals the limitations of a blast-only finish on metal prints:

-

Persistent Layer Evidence: Upon close inspection, the stair-stepping (layer lines) from the 3D printing process are still visible, especially on the curved transitions and the neck of the blade. Sandblasting hides these, but it does not erase them.

-

Surface Graininess: The finish still retains a “sand-cast” texture. It lacks the buttery-smooth refinement of a CNC-machined or hand-polished part.

-

Micro-Pits: Small pits or “pores” inherent to the SLM process remain visible on the surface. These are a natural characteristic of metal 3D printing that a standard sandblasting cycle cannot fully fill or smooth out.

Realistic Solutions with FacFox

At FacFox, we don’t over-promise; we provide the right solution for your specific budget and quality requirements. We see these parts as a great “Standard Grade” finish, but we offer more for those who need “Premium.”

Looking for a better finish than the one shown? If the sandblasted version still feels too “raw” for your project, FacFox offers advanced post-processing paths:

-

Vibratory Tumbling: To physically level the layer lines before the final blast.

-

Manual Sanding: Targeted smoothing of the “blade” faces to achieve a high-end consumer look.

-

Chemical Etching: To clean up the deep grooves in the “fir-tree” base where blasting media might not reach consistently.

Solution

- Step 1: Digital Modeling and Slicing. The 3D CAD models of the stylized turbine blades were designed and then processed through slicing software. During this stage, the geometry was divided into thin horizontal layers, and the laser scanning paths were calculated.

- Step 2: Selective Laser Melting (SLM). The parts were fabricated using SLM technology. A thin layer of aluminum alloy powder was spread across the build platform, and a high-powered fiber laser was used to selectively melt and fuse the powder according to the cross-section of the model. This process was repeated layer by layer until the full height of the parts was reached.

- Step 3: Cooling and Powder Removal. After the printing cycle was completed, the build chamber was allowed to cool in an inert gas environment to prevent oxidation. The parts were then extracted from the powder bed, and the excess un-fused aluminum powder was removed using brushes and compressed air.

- Step 4: Support Structure Removal. The sacrificial support structures, which were required to anchor the overhanging edges of the blades and the eyelets, were mechanically removed. The connection points were then roughly ground down to match the surrounding profile.

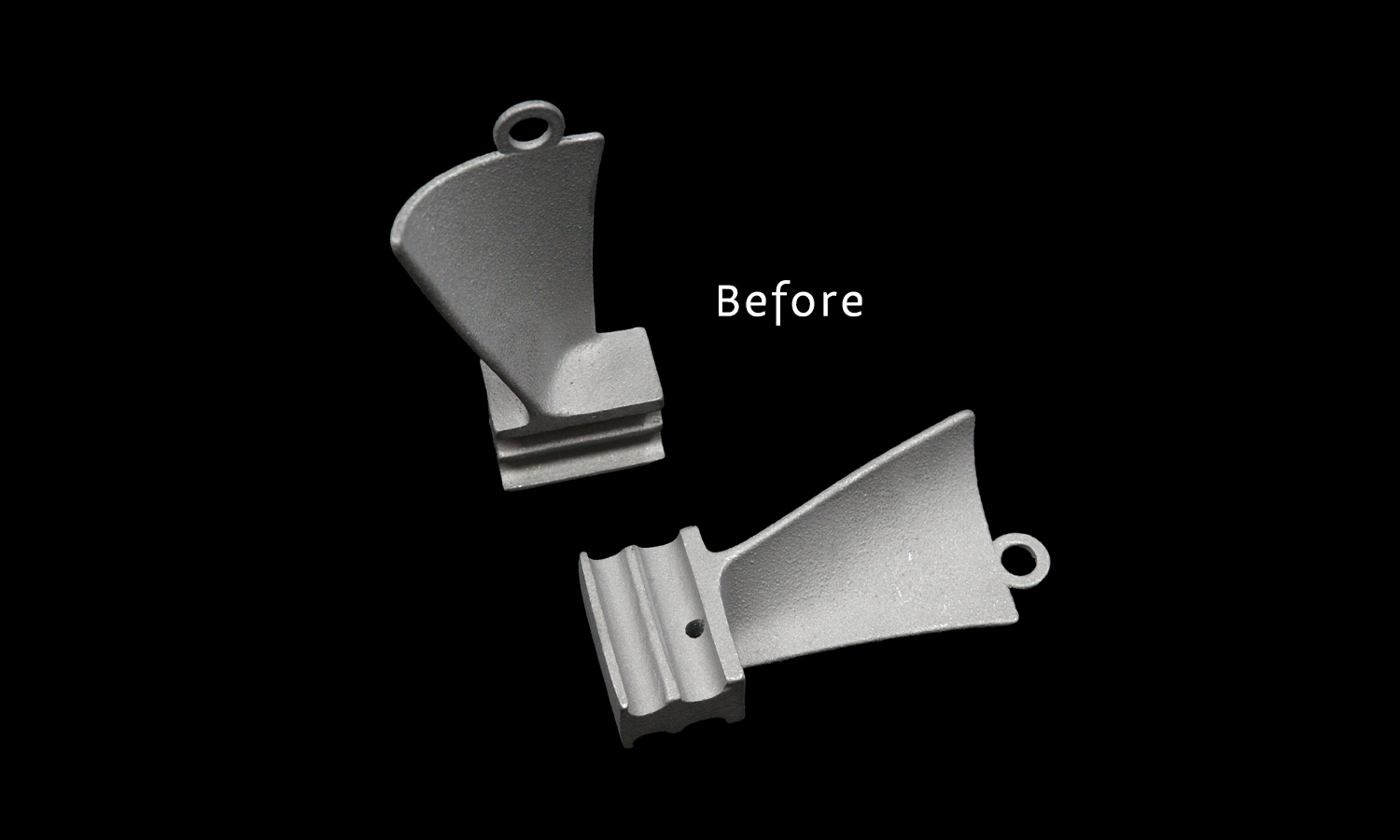

- Step 5: Initial Inspection (Raw State). An initial quality assessment was performed on the raw prints. As seen in the “Before” images, a grainy, porous texture was observed, and subtle stair-stepping effects from the layering process remained visible on the curved surfaces.

- Step 6: Sandblasting (Surface Treatment). The parts were subjected to a sandblasting process to improve the surface uniformity. Fine abrasive media was propelled against the aluminum surfaces at high pressure. This was done to “blend” the laser-melted tracks and create a more consistent matte finish.

- Step 7: Final Evaluation. The finished parts were evaluated against the original design. While the sandblasting successfully softened the industrial “raw” look and improved the tactile feel, certain imperfections, such as deep-seated layer lines and micro-porosity, were still found to be present upon close inspection.