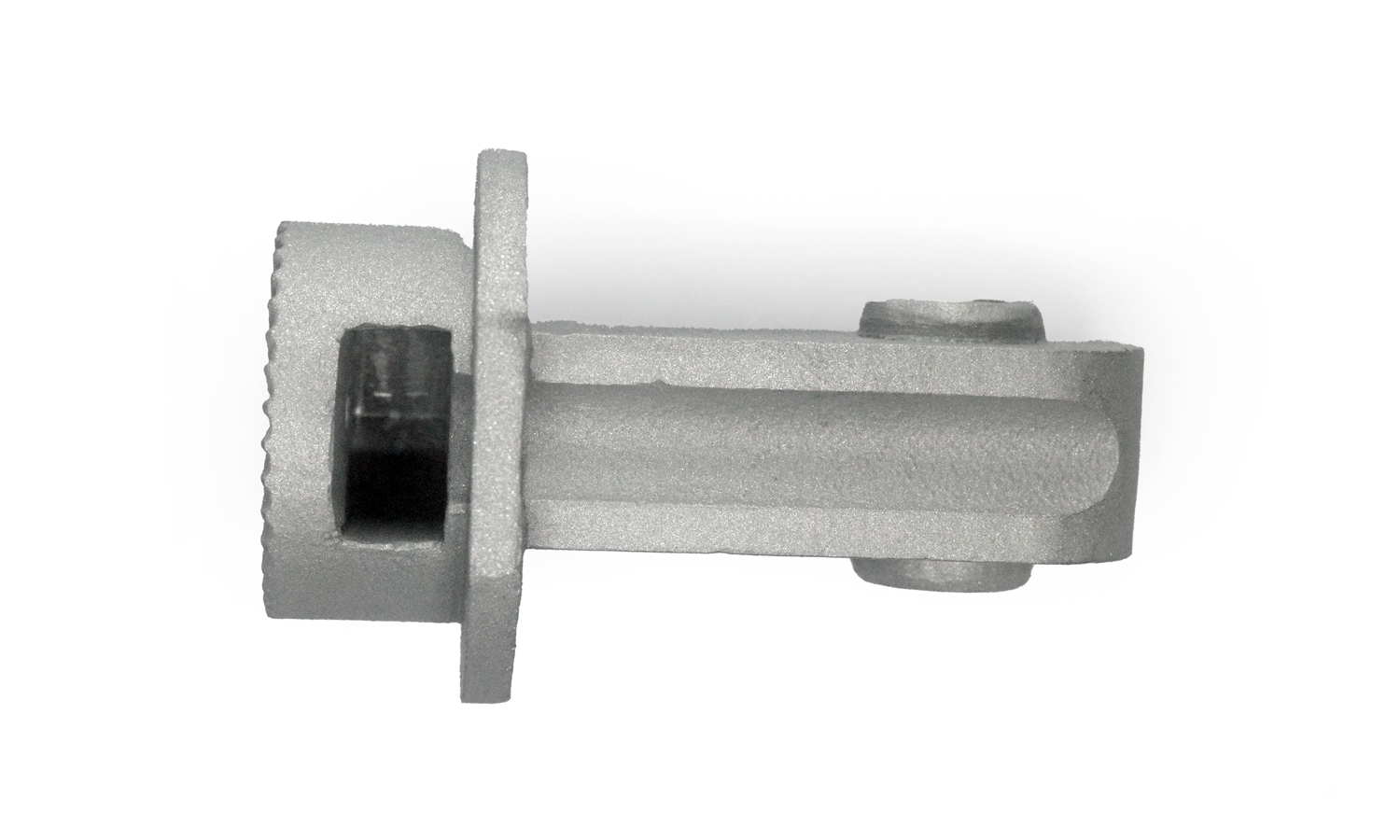

Material Metal

Quantity 1 pcs

Price Range $100-1,000

Lead Time 2 workdays

Gallery

About Project

Traditional gate hinge brackets, often made from cast iron or steel, can be heavy, prone to rust, and limited in design flexibility. But what if there was a better way? Enter SLM 3D printing and aluminum alloys!

SLM (Selective Laser Melting) 3D printing is an advanced manufacturing process that uses a high-powered laser to precisely melt and fuse powdered aluminum alloy, layer by layer, building complex shapes directly from a digital design. This technology unlocks a whole new world of possibilities for gate hinge brackets:

- Lightweight Strength: Aluminum alloys offer an excellent strength-to-weight ratio, making the brackets strong and durable without the unnecessary bulk. This is particularly beneficial for large gates or those requiring frequent operation.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that resists corrosion, ensuring the brackets remain functional and aesthetically pleasing for years to come, even in harsh environments.

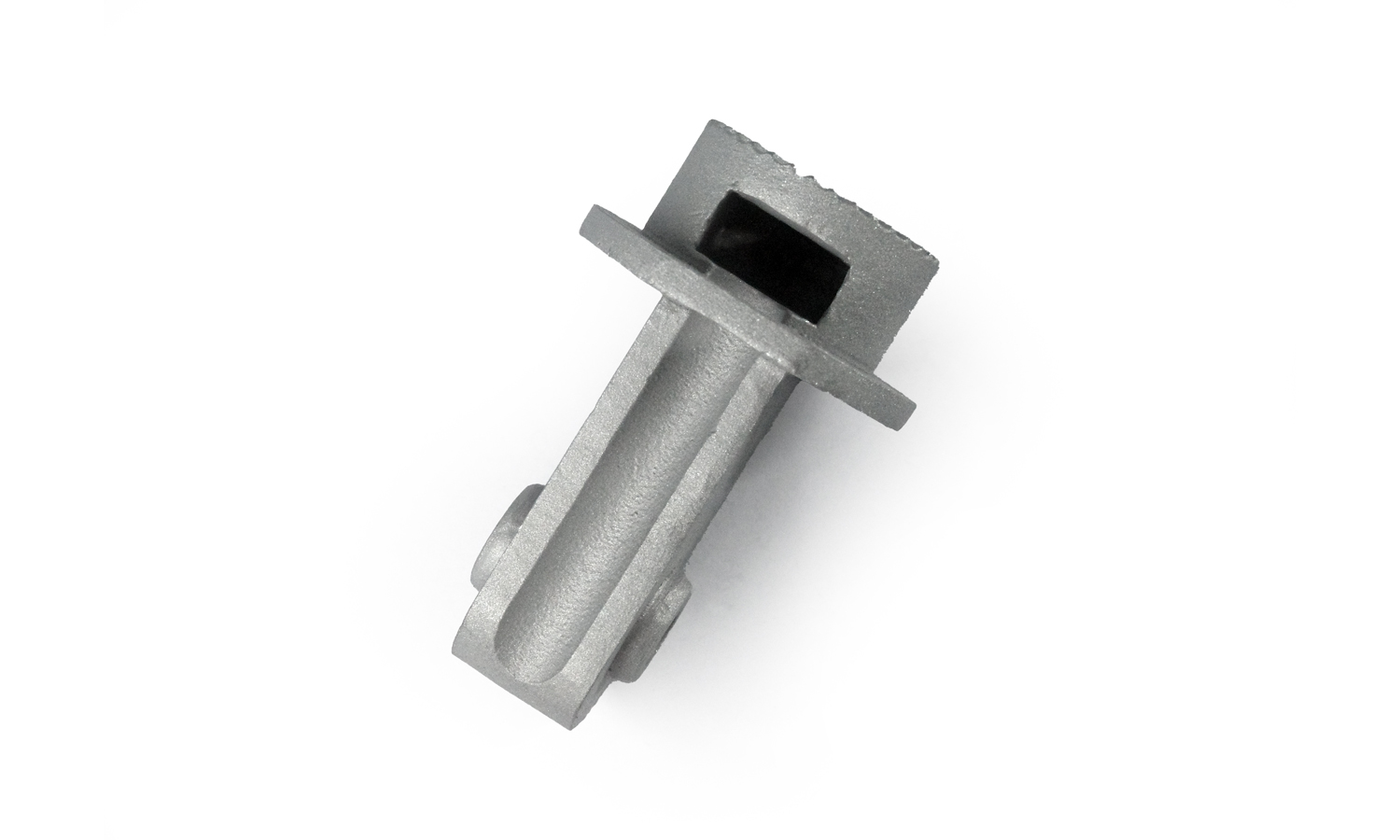

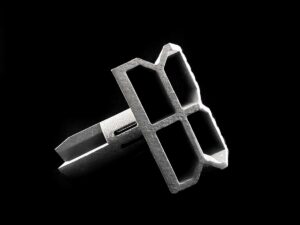

- Design Freedom: SLM 3D printing allows for intricate designs and complex geometries that would be impossible to achieve with traditional manufacturing methods. This enables the creation of customized brackets with optimized load-bearing capabilities and unique aesthetics.

- Reduced Lead Times: 3D printing eliminates the need for tooling and molds, significantly reducing lead times and enabling rapid prototyping and production.

Imagine a gate hinge bracket that is not only strong and durable but also lightweight, corrosion-resistant, and beautifully designed. SLM 3D printed aluminum alloy brackets can deliver all of this and more.

Looking to upgrade your gate hardware with cutting-edge technology?

FacFox offers high-quality aluminum 3D printing services with a wide range of aluminum alloys and expert design support. Our SLM 3D printing capabilities can produce gate hinge brackets that meet your exact specifications, delivering superior performance and aesthetics. Contact us today to learn more about how FacFox can help you create innovative and reliable gate hardware solutions.

Solution

- Step 1: CAD Design. A 3D model of the gate hinge bracket was designed using CAD software, incorporating specific requirements for functionality and aesthetics.

- Step 2: File Preparation. The CAD file was converted to an STL format and optimized for SLM 3D printing, including parameters like layer thickness and build orientation.

- Step 3: Powder Preparation. Fine aluminum alloy powder was selected based on desired material properties and carefully sieved and dried to ensure optimal quality and flowability.

- Step 4: Build Platform Setup. The SLM 3D printer’s build platform was prepared and preheated to the appropriate temperature for the chosen aluminum alloy.

- Step 5: Powder Deposition. A thin layer of aluminum alloy powder was evenly spread across the build platform by a recoater blade.

- Step 6: Selective Laser Melting. A high-powered laser was precisely directed across the powder bed, selectively melting and fusing the powder particles according to the design’s cross-sectional layer.

- Step 7: Layer Repetition. Steps 5 and 6 were repeated, layer by layer, building the gate hinge bracket additively until the entire 3D structure was complete.

- Step 8: Cooling and Removal. The finished part was allowed to cool down within the build chamber before being carefully removed from the build platform.

- Step 9: Support Removal. Any support structures used during the printing process were detached with EDM technique.

- Step 10: Post-Processing. The bracket was subjected to post-processing techniques as needed, such as heat treatment to enhance mechanical properties, machining for precise tolerances, or surface finishing for aesthetics.

- Step 11: Quality Inspection. The final product was inspected for dimensional accuracy, structural integrity, and surface quality to ensure it met the required specifications.