- SLA 3D Printed High-temp Resin-220°C Gear Test Unit

- SLA High-temp Resin-220°C Mascot Fox Miniature

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

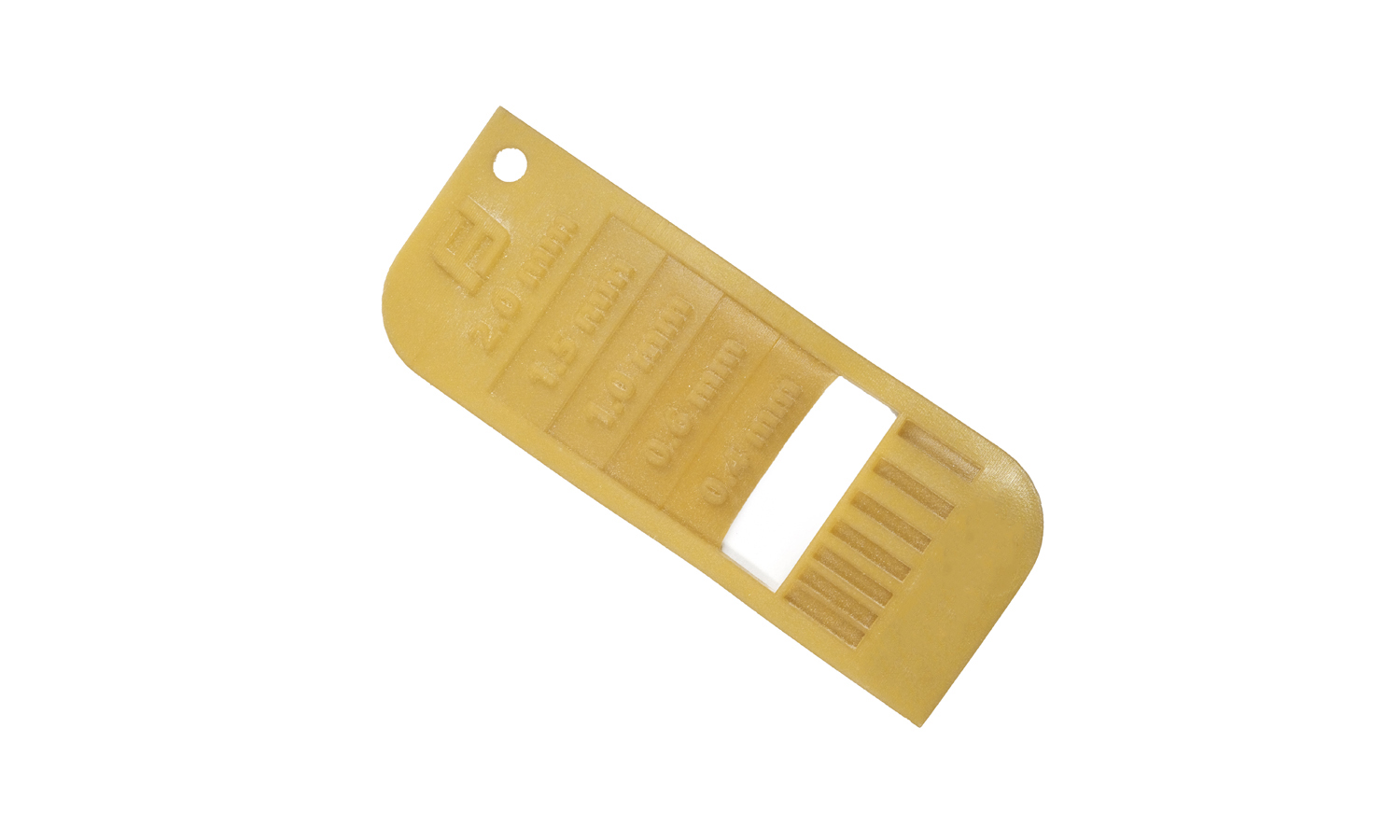

Introducing the SLA High-Temp Resin-220°C 3D Printed Thin Wall Tester, a remarkable example of precision engineering and advanced materials. This test unit is designed to evaluate the fine details and capabilities of high-temperature-resistant SLA printing.

The Thin Wall Tester is a critical tool for assessing the precision and quality of 3D prints, especially for components requiring fine, thin walls. With varying thicknesses, this test unit helps identify the limits and strengths of the printing process, ensuring optimal performance for intricate designs.

Printed with SLA High-temp Resin-220¬∞C (Temp R220), this tester exemplifies the material’s outstanding properties. Temp R220 boasts excellent temperature resistance, and after simple post-treatment, its heat deflection temperature can reach up to 227¬∞C. This makes it ideal for applications that demand high-temperature endurance, such as wind tunnels, impellers, motors, and rapid molds.

The 3D printed Thin Wall Tester showcases the exceptional accuracy and reliable surface quality of Temp R220. The ability to produce smooth, precise surfaces with minimal visible layer lines speaks to the high standards achieved with SLA technology and this advanced resin. However, the 0.2mm thickness failed to be printed, presenting challenges and highlighting the precision limits.

Additionally, the sunk vertical bars below the hollow part serve as an important test of vertical resolution, adhesion, and cooling efficiency, helping to further understand and optimize the printing process.

Why Choose FacFox for SLA High-Temp Resin Printing?

At FacFox, we specialize in delivering top-notch SLA 3D printing services using the best materials available. Our expertise with High-temp Resin-220°C ensures that your projects benefit from:

- Advanced SLA Technology: Achieve exceptional precision and detail with our state-of-the-art printers.

- High-Temp Resin Expertise: Optimal performance and high-quality results with Temp R220.

- Custom Solutions: Tailored 3D printing services to meet your specific requirements, whether it’s for prototypes, industrial parts, or intricate designs.

Experience the excellence of FacFox’s 3D printing services and discover how our expertise with High-temp Resin-220¬∞C can elevate your projects to new heights. Trust FacFox to bring your innovative ideas to life with unmatched quality and durability.

Solution

- Step 1: 3D Model Creation. A digital 3D model of the Thin Wall Tester was designed using specialized software.

- Step 2: SLA Printing Preparation. The 3D model was sliced into layers, and the SLA 3D printer was calibrated for the material.

- Step 3: Resin Dispensing. SLA High-temp Resin-220°C was dispensed layer by layer onto the build platform using a laser.

- Step 4: Layer Curing. A UV laser cured each layer of resin, solidifying it into the desired shape.

- Step 5: Build Platform Lowering. The build platform was lowered to allow for the dispensing of the next layer.

- Step 6: Post-Processing. The printed Thin Wall Tester was removed from the build platform and cleaned to remove any excess resin.

- Step 7: Curing. The tester was cured under UV light to ensure complete polymerization and optimal material properties.