- Full-Color 3D Printed Board Game Miniatures and Terrain Models

- SLA 3D Printed 1.6m Resin Tree Sculpture

Material Plastic, Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 3 workdays

Gallery

About Project

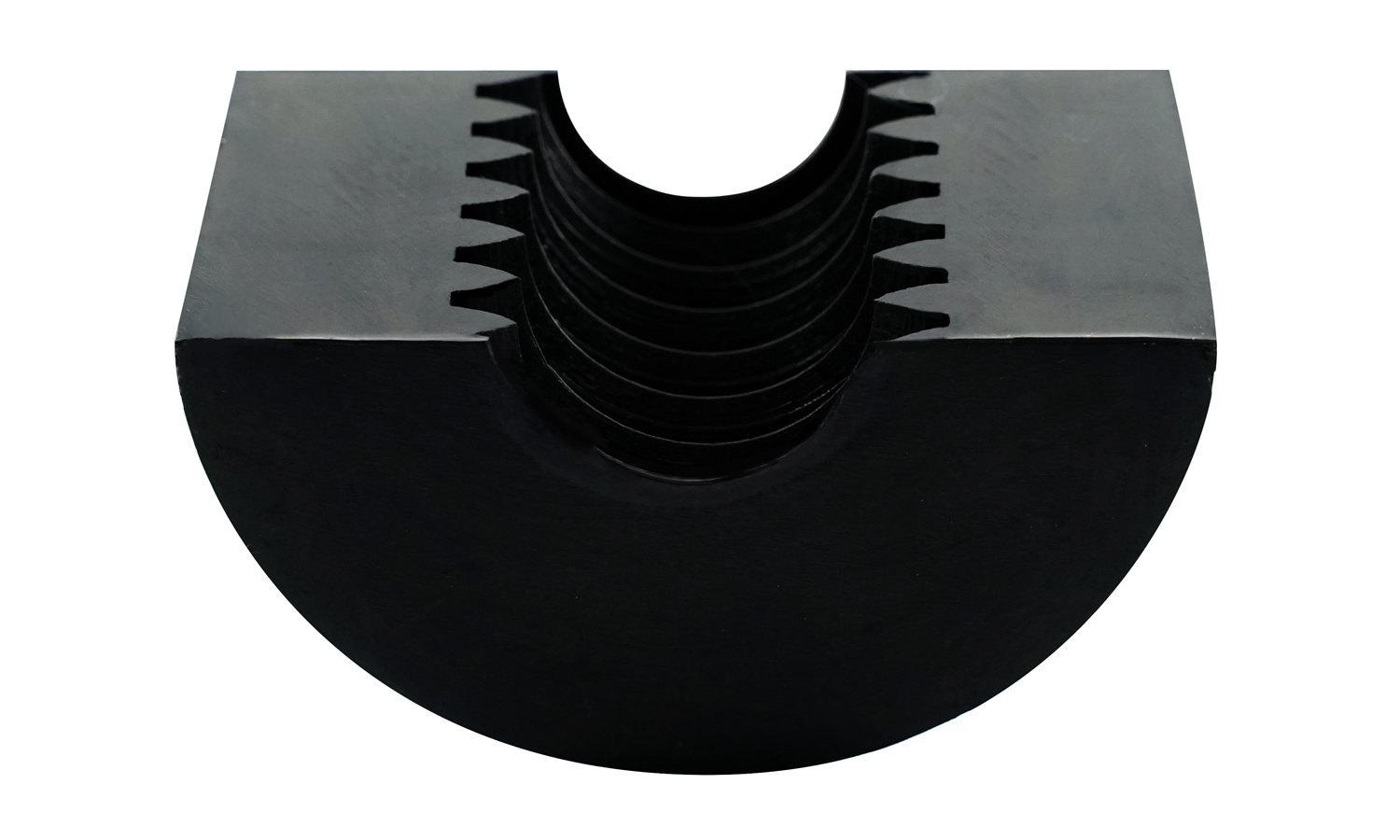

This polyurethane (PU) component was intentionally molded as a half-section to showcase the precision achievable through vacuum casting. Instead of being cut open from a full cylinder, the part was designed with a flat mold boundary, allowing the internal thread geometry to be exposed immediately after demolding. The result is a clean, perfectly symmetrical cross-section that reveals every detail of the replicated thread profile.

Though it appears metallic at first glance, the part is made entirely of rigid black PU resin. The material’s excellent flow and curing properties allow it to reproduce deep threads and sharp edges with remarkable fidelity. Each ridge and valley of the thread is clearly defined, demonstrating how polyurethane casting can capture even the most intricate mechanical features with near-injection-molding accuracy.

Such half-section samples are often used for quality inspection, mold validation, and educational display, as they allow engineers to observe how well the resin fills fine geometries and to assess surface finish and dimensional consistency. The technique also provides valuable insights during prototype development, ensuring that thread details, tolerances, and wall thicknesses meet design expectations before moving into full production.

FacFox specializes in professional PU casting for prototypes and short-run production, delivering highly accurate reproductions of complex geometries like this threaded half-section. With our advanced vacuum casting process, clients can expect reliable, production-grade results – perfect for functional testing, display, or validation of intricate design details.

Solution

- Step 1: The half-section threaded sample was modeled in CAD with a flat longitudinal parting plane so that the internal thread profile would be exposed after demolding.

- Step 2: A high-resolution master of the half-section was produced (via SLA/DLP or CNC) to ensure crisp thread fidelity, then critical surfaces were cleaned and lightly polished.

- Step 3: The master was mounted on a base with the flat face oriented as the future open mold boundary, and gates/vents/keys were planned and added to facilitate flow and registration.

- Step 4: The master and tooling features were encapsulated in RTV silicone to create a single-cavity mold; a rigid mother mold (jacket) was formed to maintain dimensional stability.

- Step 5: After cure, the silicone mold was split and opened, the master was removed, and the cavity representing the half-thread geometry was inspected for defects and air traps.

- Step 6: The mold cavity was prepared with release agent, the mold halves were indexed and clamped, and the pouring path and vents were kept clear.

- Step 7: Two-part polyurethane resin (black-pigmented, rigid grade) was metered, mixed, and degassed under vacuum to minimize entrapped air.

- Step 8: The resin was poured under vacuum into the silicone cavity until fully filled; the assembly was then cured (vacuum/pressure and oven, per resin specification) to achieve dimensional stability.

- Step 9: After curing, the casting was demolded, gates/flash were trimmed, and the flat boundary face was lightly dressed to present a clean, exhibition-grade cross-section.