- PolyJet 3D Printed Rubber Prototypes for Medical and Industrial Use

- Cheers to 10 years! Recharging our creative engines on a team trip to Xinjiang from July 16-24.

Gallery

About Project

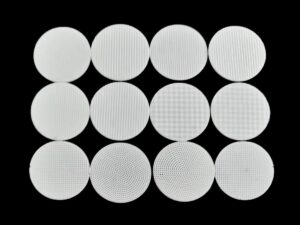

Nylon (PA12) is one of the most versatile materials used in 3D printing, known for its exceptional strength, toughness, and wear resistance. In the images above, we showcase a range of nylon 3D prints that highlight the material’s capability to produce highly functional, end-use components.

The first image displays a large precision gear ring accompanied by two fluid-handling fittings. These parts are likely used in mechanical assemblies or fluid systems, where durability and chemical resistance are critical. Nylon’s natural lubricity and low friction coefficient make it ideal for these applications.

The second image features a basket-like rotor component, possibly used in filtration, centrifuge systems, or as part of a water or chemical separation device. The dense perforation pattern and structural ribs demonstrate how nylon can be used for high-stress rotating equipment.

In the third image, we see a perforated cylindrical container that may serve as a filter basket or insert for liquid or air flow systems. The uniformity and fine detailing of the holes show the accuracy that nylon 3D printing can achieve, even with complex geometries.

All of these parts benefit from the outstanding mechanical properties of nylon, including high tensile strength, impact resistance, and thermal stability, making them perfect for prototyping and low-volume manufacturing of industrial parts.

Why Choose FacFox for Nylon 3D Printing?

At FacFox, we specialize in high-performance nylon 3D printing using technologies like SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion). Our services deliver parts with excellent mechanical performance, smooth surface finishes, and consistent dimensional accuracy. Whether you’re creating functional prototypes or ready-for-use mechanical components, FacFox provides cost-effective, scalable solutions with rapid turnaround times. Try our nylon 3D printing service today and experience professional-grade manufacturing at your fingertips.

Solution

- Step 1: 3D Models Were PreparedThe digital 3D models of the gear ring, fittings, rotor basket, and perforated container were created using CAD software. The models were optimized for SLS printing, ensuring proper wall thickness, resolution, and orientation.

- Step 2: Models Were Sliced and ArrangedThe finalized CAD files were sliced into layers and imported into the SLS printer software. The parts were then strategically arranged within the build chamber to maximize space utilization and minimize post-processing efforts.

- Step 3: Nylon Powder Was PreheatedA bed of PA12 nylon powder was preheated to just below its melting point to reduce thermal distortion during laser sintering.

- Step 4: Layers Were Selectively SinteredA high-powered laser was directed onto the powder bed, where it selectively sintered each cross-section of the parts layer by layer. The laser fused the powder particles together in precise areas according to the 3D model design.

- Step 5: Build Chamber Was CooledAfter printing, the entire build chamber was allowed to cool down gradually inside the printer to avoid warping or internal stress within the parts.

- Step 6: Parts Were Removed and CleanedThe printed parts were carefully removed from the powder cake and excess nylon powder was brushed or blasted off using compressed air or a media blaster.

- Step 7: Post-Processing Was PerformedThe parts were inspected for accuracy and cleaned thoroughly. If necessary, additional surface finishing, drilling, or dyeing was performed depending on the end-use requirements.

- Step 8: Final Parts Were DeliveredThe completed parts were packaged and delivered, ready for mechanical assembly or real-world industrial use.