- SLA 3D Printed Frosted Clear Resin Avalokitesvara Buddha

- SLA 3D Printed White Blade-like Resin Boards

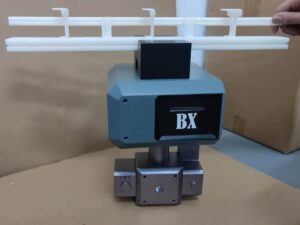

Material Metal

Quantity 4 pcs

Price Range $1,000-5,000

Lead Time 4 workdays

Gallery

About Project

Looking for high-performance, custom propeller hubs for your machines? FacFox 3D printing has you covered! We specialize in Selective Laser Melting (SLM), a cutting-edge technology that produces incredibly strong and durable metal parts.

SLM: Perfect for Complex, Geometrically Intricate Parts

Our SLM process is perfect for creating complex, geometrically intricate parts like SS316L blade propeller hubs. These hubs offer several advantages over traditional manufacturing methods:

- Design Freedom: SLM allows for intricate designs that would be impossible with traditional techniques like casting or machining. This opens doors for optimizing propeller performance and efficiency.

- Lightweight Strength: SS316L stainless steel is known for its exceptional strength-to-weight ratio. SLM 3D printing allows for the creation of lightweight hubs that can handle demanding applications.

- Corrosion Resistance: SS316L offers superior corrosion resistance, making it ideal for use in marine environments or applications exposed to harsh chemicals.

Beyond Propeller Hubs: FacFox SLM 3D Printing for All Your Machine Components

SLM 3D printing isn’t limited to just propeller hubs. FacFox can handle a wide range of machine components, including:

- Cylindrical Metal Parts with Flanges: Think custom pipe reducers with flanges for easy attachment. SLM printing ensures perfect dimensions and a strong, leak-proof connection.

- Clamps and Fasteners: Need heavy-duty clamps or fasteners for your machinery? We can 3D print them in SS316L for superior strength and durability.

Why Choose FacFox 3D Printing for Your Machine Components?

- Quality and Precision: Our SLM printers deliver exceptional dimensional accuracy and part quality, ensuring perfect fit and function for your machine components.

- Fast Turnaround Times: FacFox understands the importance of keeping your machines running. We offer fast turnaround times to get you the parts you need quickly.

- Design for Manufacturability (DFM) Expertise: Our team can help you optimize your designs for SLM printing, ensuring efficient production and cost-effectiveness.

Ready to Take Your Machines to the Next Level?

Contact FacFox today to discuss your 3D printing needs for machine components. We’ll work with you to design and produce high-performance, custom parts that meet your exact specifications. Let FacFox help you take your machines to the next level!

Solution

- Step 1: Design Creation. A digital 3D model of the propeller hub was first created. This model captured the complex geometry and incorporated features that would be impossible with traditional manufacturing methods.

- Step 2: Material Selection. SS316L stainless steel powder, known for its exceptional strength-to-weight ratio and corrosion resistance, was chosen for the printing process.

- Step 3: Printing Process. The 3D printer meticulously laid down thin layers of the SS316L powder across the build platform. A high-powered laser beam then selectively sintered, or melted, each layer together, following the digital blueprint. This process was repeated layer by layer until the entire propeller hub was built.

- Step 4: Support Removal. Once printing was complete, any support structures used during the printing process were carefully removed from the finished hub with wire cut EBM technique.

- Step 5: Post-Processing. The propeller hub may have undergone additional post-processing steps such as heat treatment or surface finishing to achieve the desired final properties.

- Step 6: Quality Control. Finally, the completed SS316L blade propeller hub underwent rigorous quality control checks to ensure it met all dimensional and performance specifications.