- Compression Molded Polyurethane Pizza Oven Door L Hinge Assembly

- Open Cast Molded Polyurethane Purple Spider for Jaw Couplings

Gallery

About Project

Are you looking for high-quality aluminum miniature belt pulleys for your project? If so, you might be interested in FacFoxŌĆÖs miniature CNC turning services.

FacFox is a leading online platform that provides fast and reliable CNC machining services for various industries. They have a team of experienced engineers and machinists who can handle any design challenge and deliver your parts with high precision and accuracy.

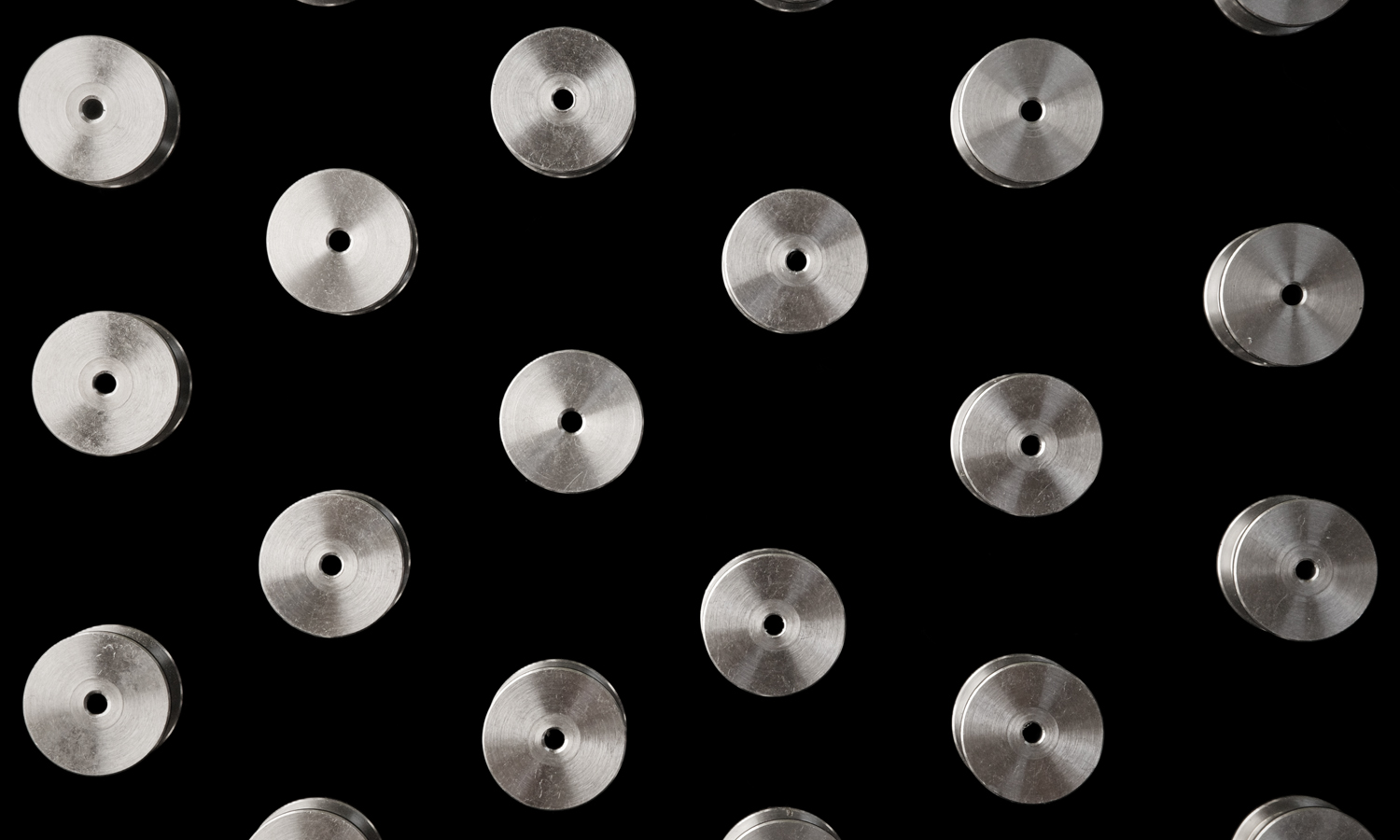

One of their recent projects was to produce a batch of CNC-turned aluminum miniature belt pulleys for a client. These pulleys are very small, measuring about only 12 mm in diameter and 8 mm in height. They are used as end-use parts for a belt drive system that requires high performance and durability.

The pulleys were machined from 6061 aluminum alloy, which is a strong and lightweight material that can withstand wear and tear. The pulleys have a smooth surface finish with visible machining marks, as no post-processing was required by the client. The pulleys also have a central bore and two set screws to secure them to the shaft.

FacFox was able to produce┬Ā500┬Āpieces of these pulleys in just┬Ā7┬Ādays, thanks to their advanced CNC turning machines and efficient workflow. The client was very satisfied with the quality and speed of the service, and praised FacFox for their professionalism and communication.

If you need CNC-turned aluminum miniature belt pulleys or any other CNC-machined parts, you can trust FacFox to deliver them with excellence and affordability. You can upload your 3D model on their website and get an instant quote within minutes. You can also choose from a variety of materials, finishes, and quantities to suit your needs.

FacFox is your one-stop shop for all your CNC machining needs. Contact them today and get started on your project!

Solution

- Step 1: The 3D model of the pulley was uploaded by the client on FacFoxŌĆÖs website and an instant quote was generated.

- Step 2: The order was confirmed by the client and the payment was made.

- Step 3: The 3D model was converted into a CNC program by FacFoxŌĆÖs engineers using CAM software.

- Step 4: The CNC program was transferred to the CNC turning machine and the 6061 aluminum alloy material was loaded into the machine.

- Step 5: The CNC turner was started and the pulley was machined from the material using a rotating cutting tool.

- Step 6: The pulley was inspected for quality and accuracy using a coordinate measuring machine (CMM).

- Step 7: The pulley was cleaned and packaged for shipping. The tracking number was sent to the client.