Wire EDM Cut and Electroplated 3mm-thick Stainless Steel Earrings

- SLA 3D Printed Big Red Crab Models for a Restaurant

- A Designer Turned Her Daughter’s Doodles into Toy Bags with SLA 3D Printing

Posted on 2021-07-30 in Jewelry ┬Ę ńÅĀÕ«Ø

Process Laser Cutting, Polish, Electroplate

Material Metal

Quantity 20 pcs

Price Range $100-1,000

Lead Time 15 workdays

Material Metal

Quantity 20 pcs

Price Range $100-1,000

Lead Time 15 workdays

Gallery

About Project

The stainless steel earrings are made for a student designer. She cared about the environment and asked about waste disposal. This is also what FacFox concerns about. Although the resin we use cannot be recycled after being cured, 70% of the nylon powder can be reused, and all the metal scraps are collected and recycled by professional companies.

Solution

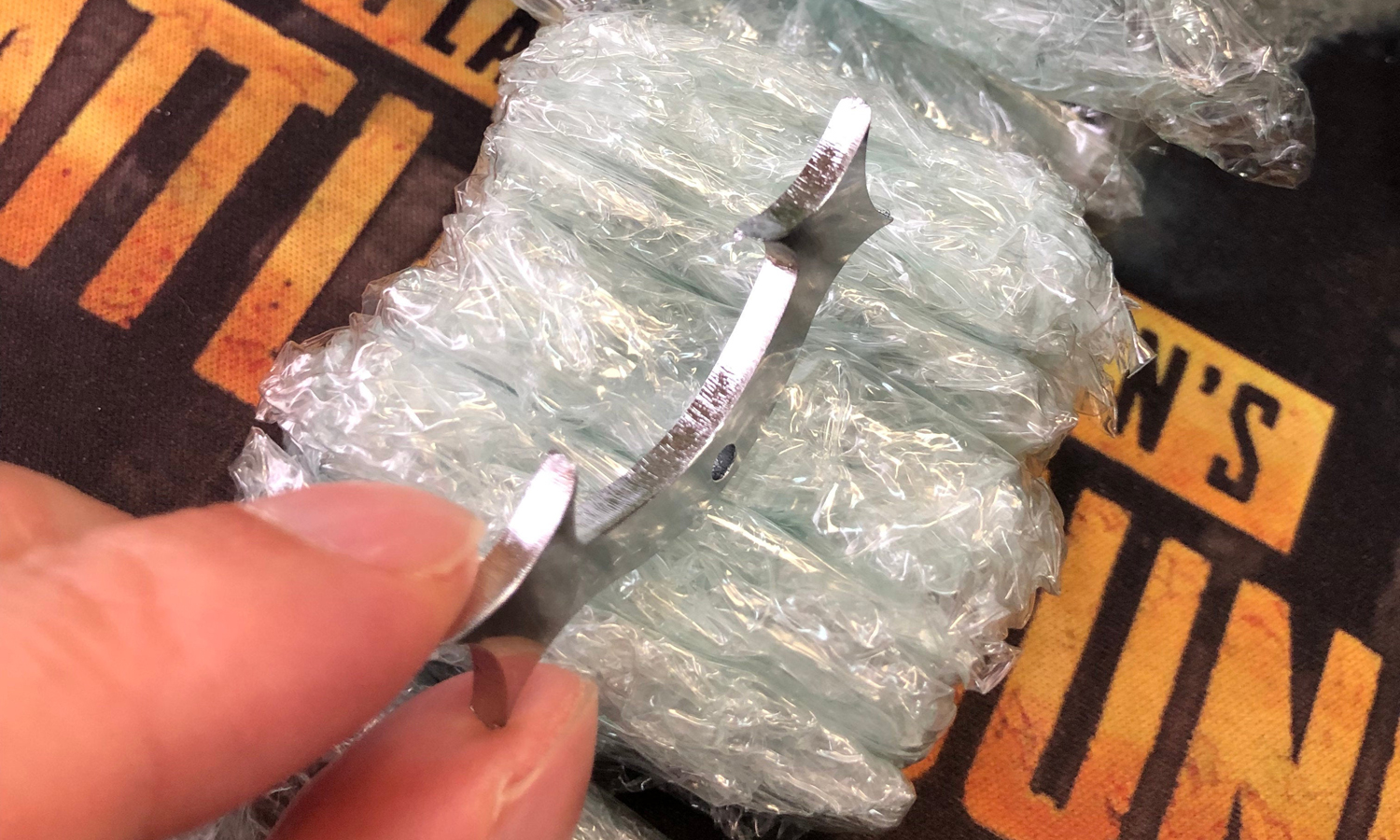

- Step 1: The client first intends to make 3.5mm thick earrings with the laser cutting technique, but we only have 3mm and 4mm thick stainless steel sheets. And the wire cutting technique can work better with such thick sheets than laser cutting. The laser may not be able to cut out the holes. After our engineer gives the quote of 3mm and 4mm earrings, the client accepts the plan of 3mm thick wire-cut earrings.

- Step 2: The client asks about the surface of wire cut parts. We show her some sample photos, the surface is smooth while there are also visible scratches. To ensure a glossy and good-looking surface, the client orders the electroplating service.

- Step 3: During the EDM process, the stainless steel sheet is placed into dielectric fluid, and a wire is fed through the submerged metal component. An electric current is sent through the part to create the sparks that will ultimately help form the desired shape of the component. Then we polish the parts and electroplate them with nickel.