- SLA 3D Printed and Painted Handheld Gaming Console Prototype

- LCD 3D Printed Lifelike Grey Resin Bear Models

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

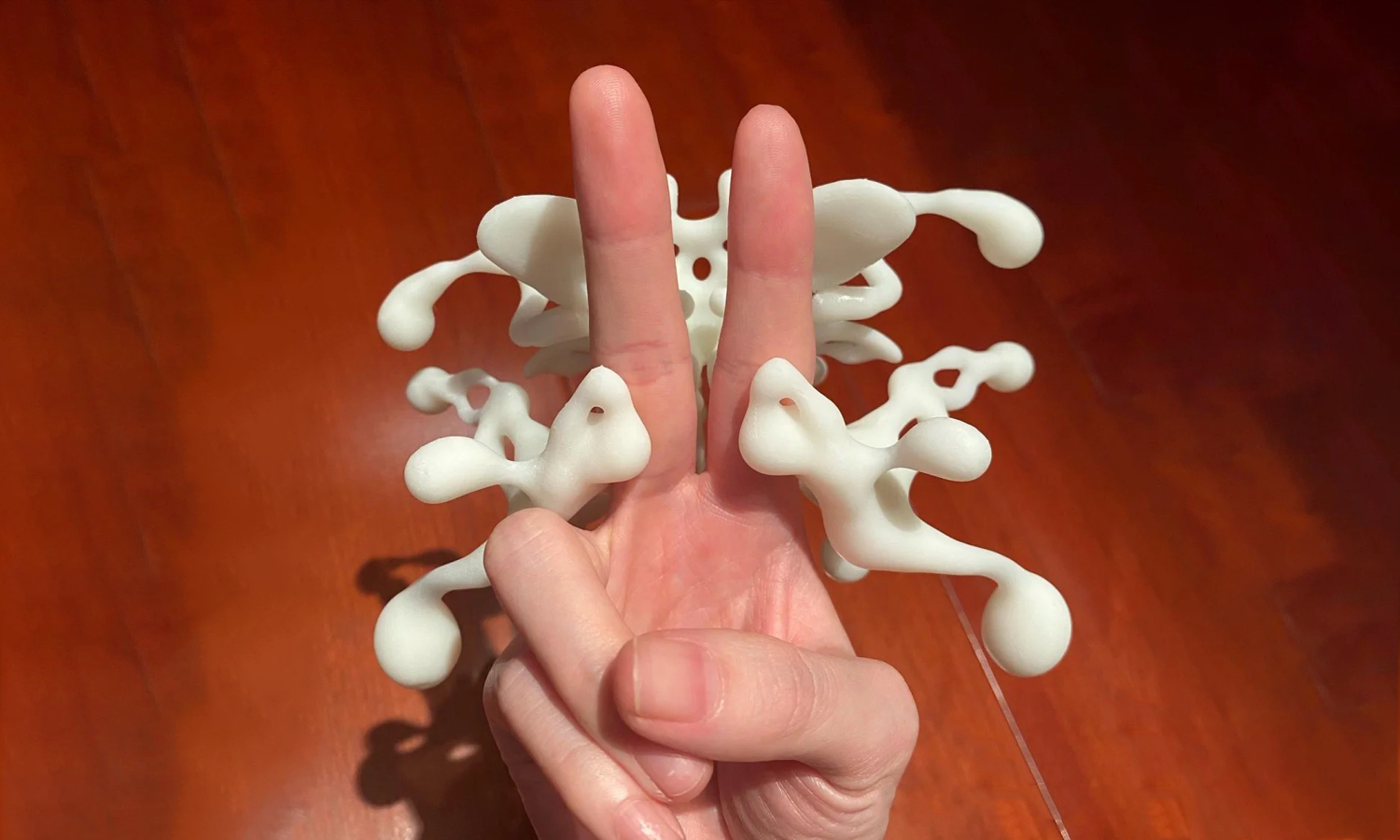

Are you looking for a unique and creative way to express yourself? Do you want to stand out from the crowd with a stunning accessory that showcases your personality and style? If so, you might be interested in the 3D-printed double-finger ring prototype!

This ring is not your ordinary jewelry. It is a masterpiece of 3D printing, made with Stereolithography (SLA) technology, which uses a laser to cure liquid resin into solid layers of intricate shapes and details. The result is a high-quality, durable, and smooth ring that looks like a melting wax insect monster. The ring is larger than your hand, so it will definitely catch everyone’s attention and spark conversations.

The ring was designed and printed by FacFox, a leading online 3D printing service provider in China. FacFox offers a wide range of 3D printing materials, technologies, and solutions for prototyping and manufacturing. Whether you need plastic, metal, rubber, or even color 3D printing, FacFox can handle it with fast turnaround and low cost.

FacFox is especially suitable for students who want to unleash their creativity and bring their ideas to life. FacFox has a user-friendly online platform where you can upload your 3D model, get instant quotes, order 3D printed parts, and receive them in just a few days. You can also browse our case studies and material guides to get inspired and learn more about 3D printing.

Solution

- Step 1: The 3D model of the ring was designed by a professional jewelry designer using a 3D modeling software. The ring had a hollow and curved shape, with many holes on the surface. The ring was larger than a hand, so it was very noticeable and impressive.

- Step 2: The 3D model of the ring was uploaded to FacFox’s online platform, where the material, technology, and quantity were selected. The material chosen for the ring was SLA Generic Resin, which is a high-quality, durable, and smooth resin that can produce fine features and details. The technology chosen was SLA 3D printing, which is the most common resin 3D printing process that uses a laser to cure liquid resin into solid layers of intricate shapes and details. The quantity chosen was one, as this was a prototype.

- Step 3: The 3D model of the ring was sliced into thin layers, and the optimal orientation, support structures, and raft were added. The support structures and raft were necessary to prevent the ring from collapsing or warping during the printing process.

- Step 4: The SLA 3D printer was prepared by filling the resin tank with SLA Generic Resin and leveling the build platform. The build platform was positioned in the tank of liquid resin, at a distance of one layer height from the surface of the liquid.

- Step 5: The SLA 3D printing process was started by exposing the first layer of resin to a UV laser, which selectively cured and solidified the resin according to the 3D model. The build platform was then lifted up by one layer height, and the resin tank was tilted to allow fresh resin to flow over the cured layer. The process was repeated until the entire ring was printed.

- Step 6: The printed ring was removed from the build platform and washed with isopropyl alcohol to remove any excess resin. The support structures and raft were then broken away from the ring using pliers or a cutter. The ring was then placed in a UV curing chamber to further solidify and strengthen the resin.

- Step 7: The final ring was inspected for any defects or flaws, and polished or painted if needed. The ring was then ready to be worn or displayed as a unique and creative accessory.