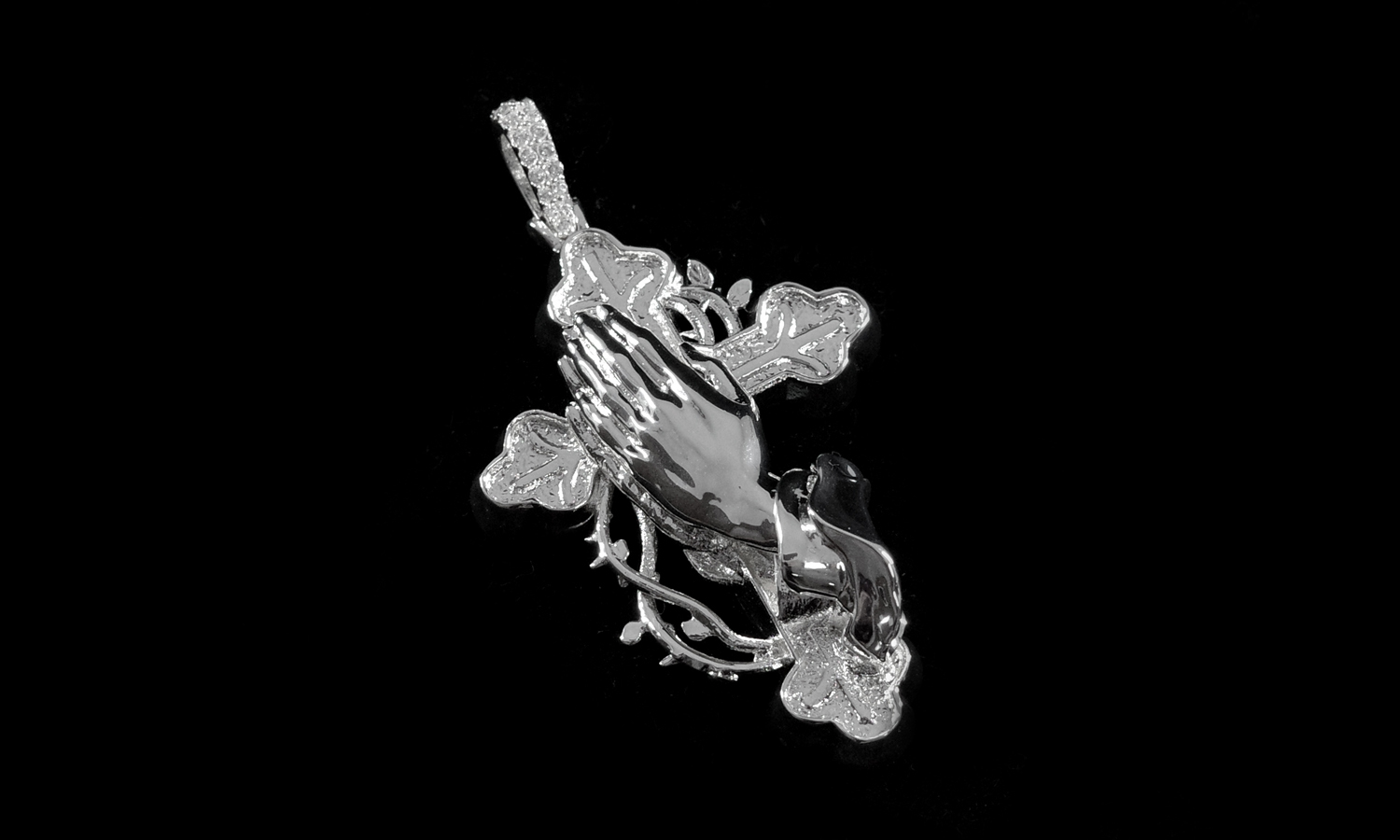

- Silver Angel of Death Necklace Pendant Cast from 3D Printed Pattern

- Rose Gold Plated Silver Jesus Pendant Cast from 3D Printed Wax Pattern

Material Resin, Metal

Quantity 10 pcs

Price Range $100-1,000

Lead Time 7 workdays

Gallery

About Project

Are you looking for a unique and meaningful gift for yourself or someone you love? Do you want to express your faith and devotion in a beautiful and elegant way? If so, you might be interested in our Silver 925 Cross with Praying Hand Pendant, cast from 3D printed pattern.

This pendant is a stunning piece of religious jewelry that features a cross, a pair of praying hands, and a ring of diamonds. The cross is designed to look like it has suffered hammer and chisel, symbolizing the suffering and sacrifice of Jesus Christ. The praying hands represent the power and comfort of prayer, as well as the gratitude and humility of the faithful. The ring of diamonds adds a touch of sparkle and luxury, enhancing the beauty and value of the pendant.

The pendant is made of high-quality silver 925, which is a durable and hypoallergenic metal that does not tarnish or corrode easily. The silver version is heavier and has a better texture than the clear resin version we made. The pendant is cast from a 3D-printed pattern, which ensures a high level of accuracy and detail.

We proudly offer this pendant as part of our manufacturing services for religious pieces of jewelry and decoration designer CGIChains. FacFox has a team of experienced and professional designers, engineers, and craftsmen who can help you turn your ideas into reality. Whether you need a single piece or a large batch, we can handle it with speed and quality.

For quoting, please upload your files or send to info@facfox.com, we will reply in one workday. Thank you for choosing FacFox, your trusted partner for 3D printing and manufacturing.

Solution

- Step 1: A 3D model of the pendant was created by @CGIChains, then converted into a 3D printable file format, such as STL. The file was then uploaded to our online platform and processed by our engineers.

- Step 2: The 3D printed pattern was made using a resin-based 3D printer. The resin was cured by a UV light source, forming a solid and detailed pattern of the pendant.

- Step 3: The 3D printed pattern was removed from the printer and cleaned of any excess resin. The pattern was polished and then inspected for any defects or errors, and corrected if needed.

- Step 4: The 3D printed pattern was used to make a mold for casting. The pattern was placed inside a metal flask and surrounded by a special material called investment. The investment was heated to a high temperature, causing the pattern to melt and burn out, leaving a hollow cavity in the shape of the pendant.

- Step 5: The mold was filled with molten silver 925, which was poured into the cavity through a sprue. The silver 925 was allowed to cool and solidify, forming the cast pendant.

- Step 6: The cast pendant was removed from the mold and separated from the sprue. The pendant was then polished and finished, removing any rough edges or imperfections.

- Step 7: The diamonds were attached to the top of the pendant. The diamonds were carefully aligned and secured, adding a touch of sparkle and luxury to the pendant. The pendant was then packaged and shipped to the customer.