- SLM 3D Printed Aluminum 6061 Smart One-Hand Bottle Opener

- DMLS 3D Printed Titanium Alloy Ice Cream Top

Material Metal

Quantity 1 pcs

Price Range $100-1,000

Lead Time 2 workdays

Gallery

About Project

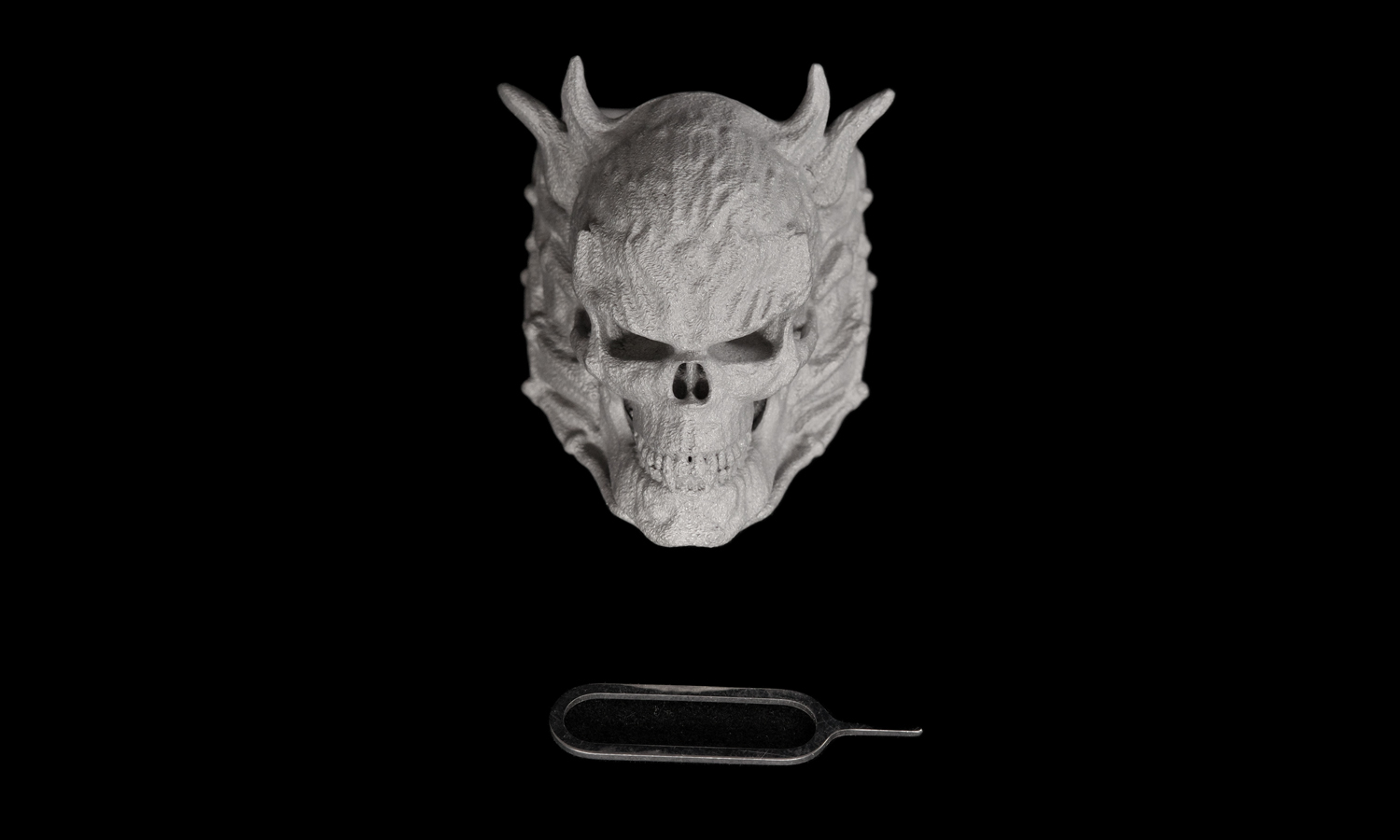

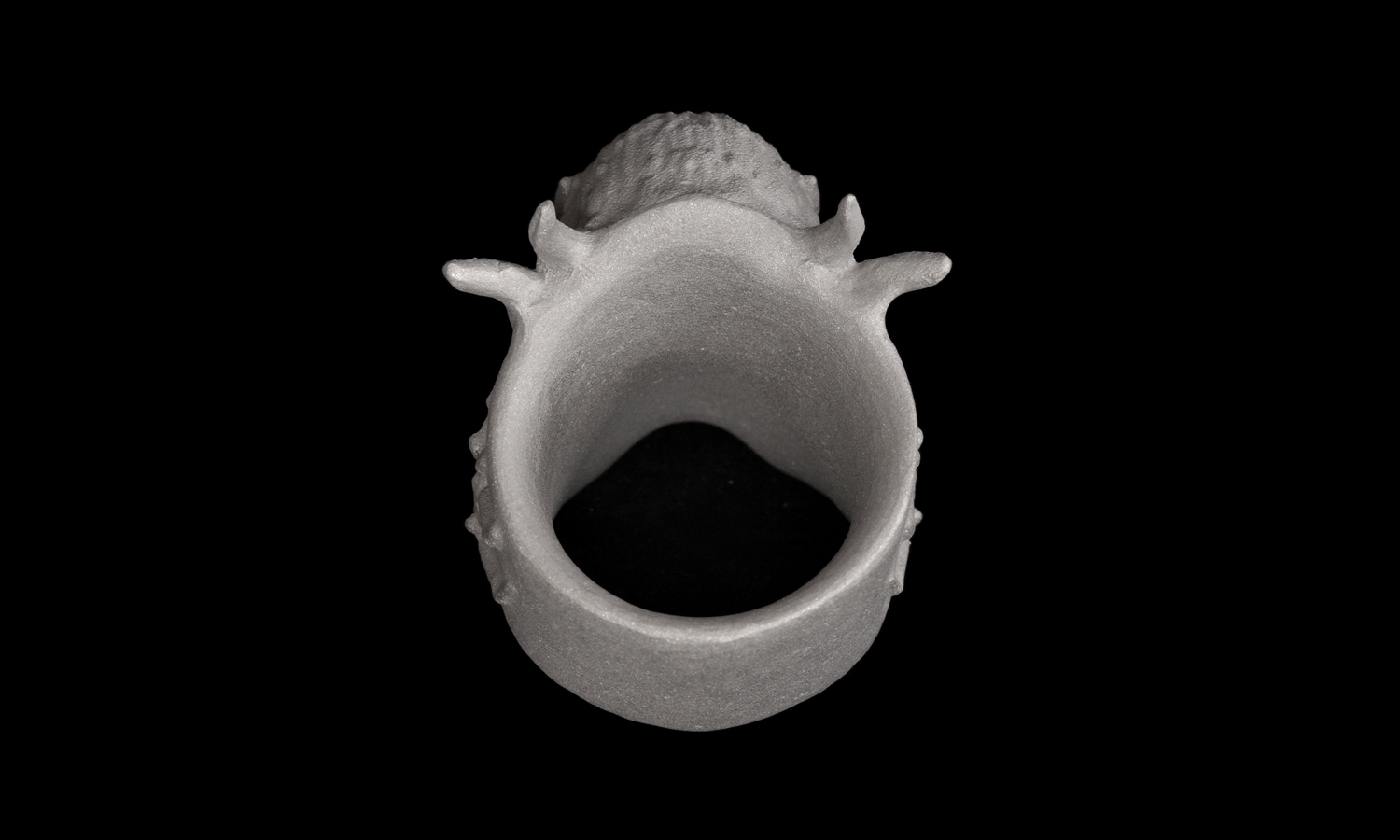

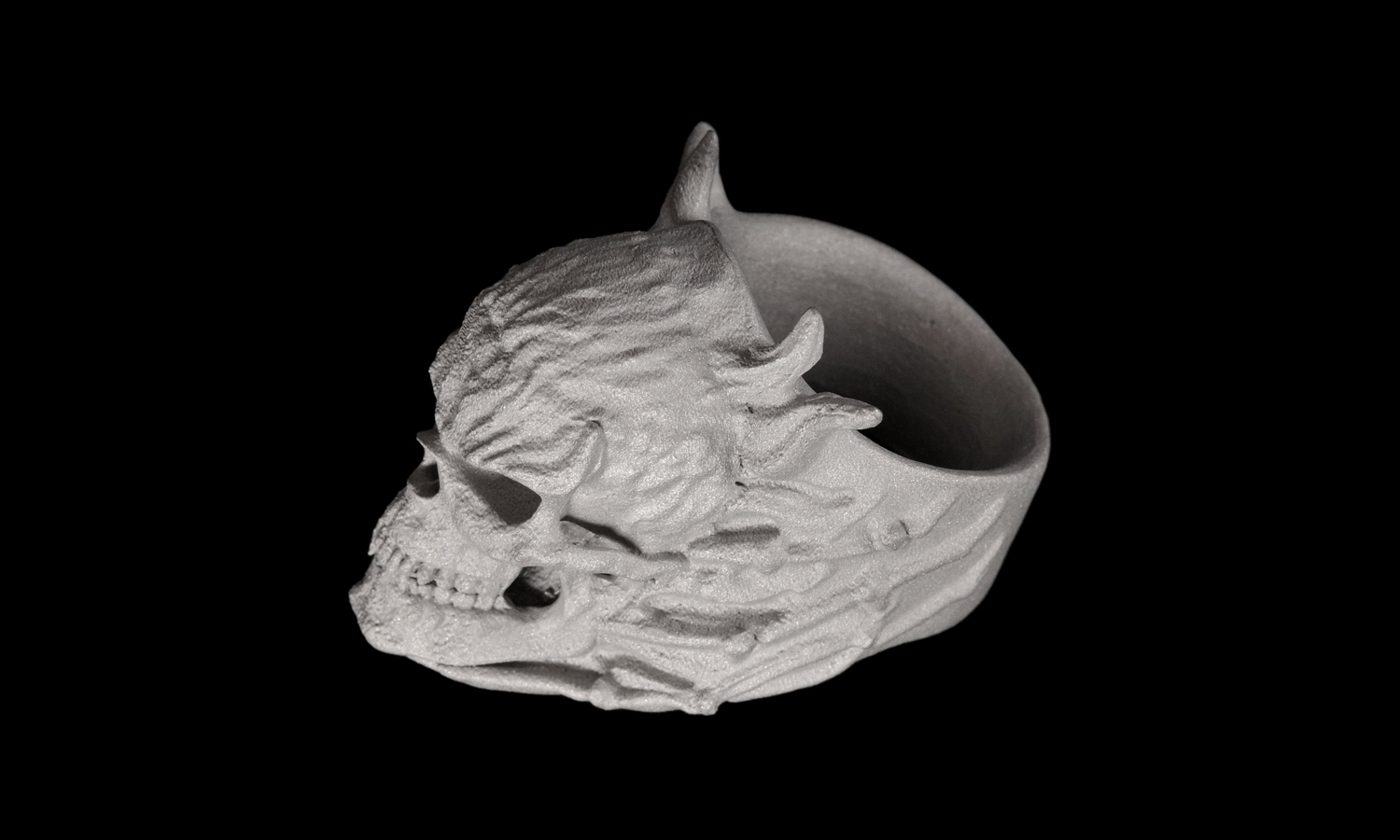

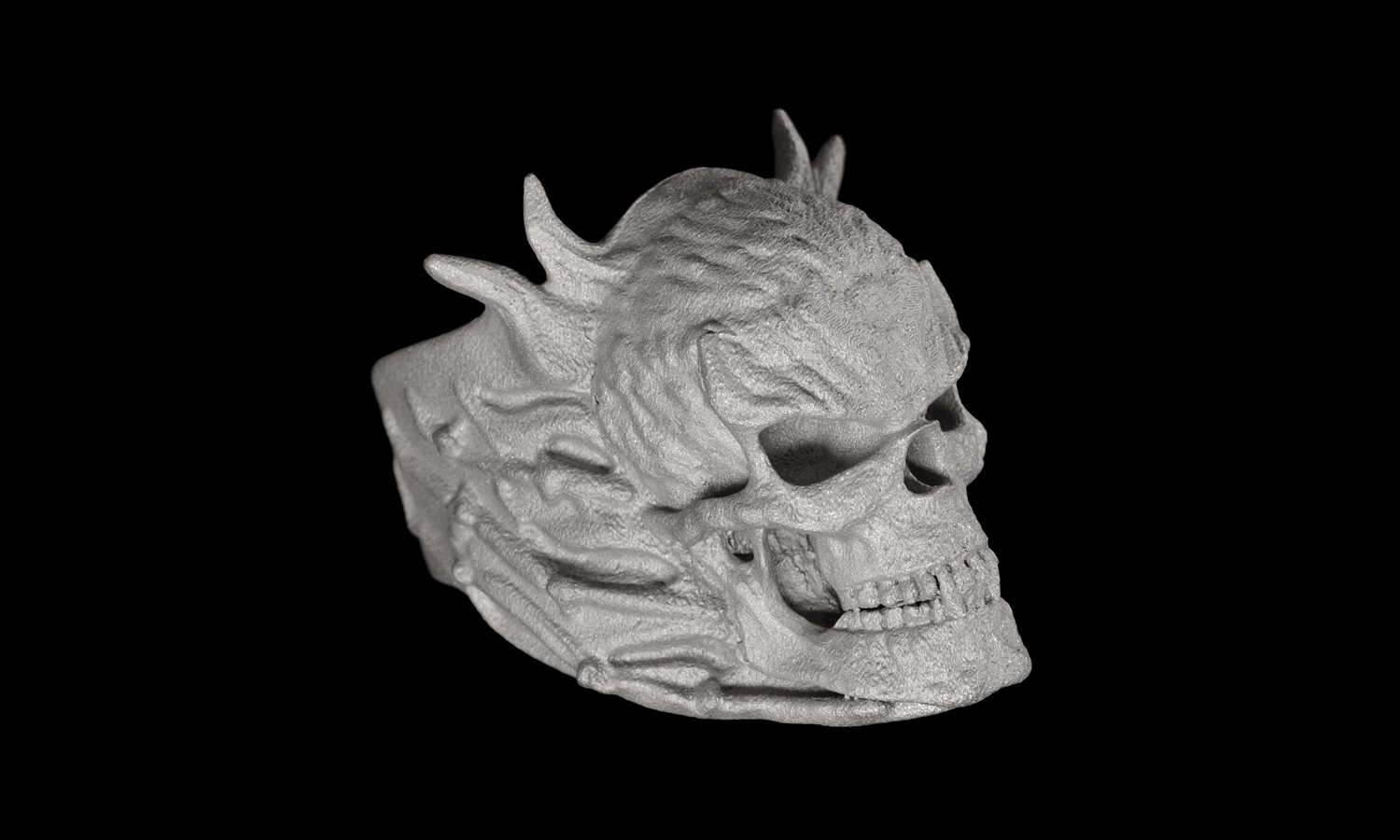

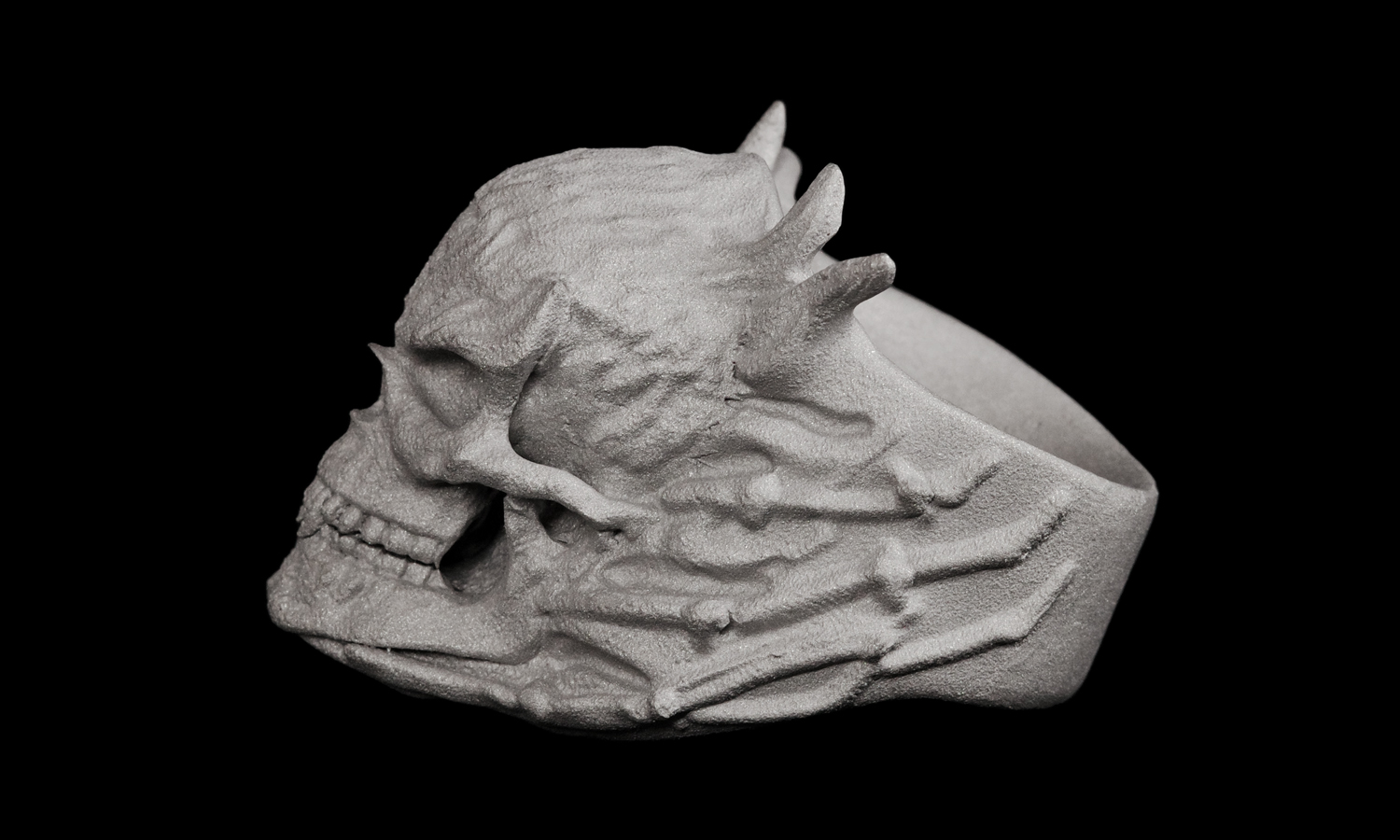

If youŌĆÖre looking for a unique and eye-catching accessory to show off your style, you might want to check out this SLM 3D printed SS316L evil skull ring. This ring is not for the faint of heart, as it features a detailed and realistic skull design that looks like it came straight out of a horror movie.

But donŌĆÖt be scared, this ring is actually a masterpiece of 3D printing technology. It was created using Selective Laser Melting (SLM), which is a process that uses a high-powered laser to fuse metal powder layer by layer into solid parts. SLM can produce complex and intricate geometries that are impossible or impractical to make with traditional metal manufacturing methods.

This ring is made of SS316L, which is a type of stainless steel that has high corrosion resistance and durability. SS316L is also biocompatible, meaning it wonŌĆÖt cause allergic reactions or irritations when worn on the skin. SS316L is one of the many materials that can be used with SLM, along with titanium, aluminum, cobalt-chrome, nickel alloys, and more.

The digital model of this ring was downloaded from this page: https://www.cgtrader.com/free-3d-print-models/jewelry/rings/evil-skull-ring-01. It was designed by a talented 3D artist who goes by the name of 3dprintmodelstore. The model has over 10,000 downloads and 4.9 stars rating from the users who have tried it.

This ring is not for sale, as it was printed as a sample to showcase the amazing quality and precision of SLM 3D printing. If you want to get your own custom-made metal parts or products using SLM, you should contact FacFox, the leading online platform for 3D printing services.

FacFox has a team of experienced engineers and designers who can help you with your 3D printing projects from start to finish. They have access to the latest and most advanced SLM 3D printers in the market, which can produce high-quality metal parts with fine details and smooth surfaces.

Whether you need prototypes, functional parts, or artistic pieces, FacFox can handle any SLM 3D printing request with fast turnaround time and competitive prices. You can upload your 3D models on their website and get an instant quote for your order. You can also choose from various finishing options and shipping methods to suit your needs.

FacFox is your one-stop shop for all your SLM 3D printing needs. Visit their website facfox.com today and discover the endless possibilities of metal 3D printing with FacFox!

Solution

- Step 1: A CAD model of the ring was downloaded from cgtrader.com and exported into an STL file format.

- Step 2: The STL file was uploaded to a SLM 3D printer, which used a high-power laser beam to selectively fuse thin layers of SS316L metal powder together.

- Step 3: The process was repeated layer by layer until the desired shape of the ring was created.

- Step 4: The ring was removed from the printer and cleaned of any excess powder.

- Step 5: It was subjected to a stress relief treatment per the ASTM 3301 standard, which reduced the internal stresses caused by the rapid heating and cooling of the metal material during the SLM process.

- Step 6: The ring was inspected for quality and accuracy.