Material Metal

Quantity 1 pcs

Price Range $100-1,000

Lead Time 2 workdays

Gallery

About Project

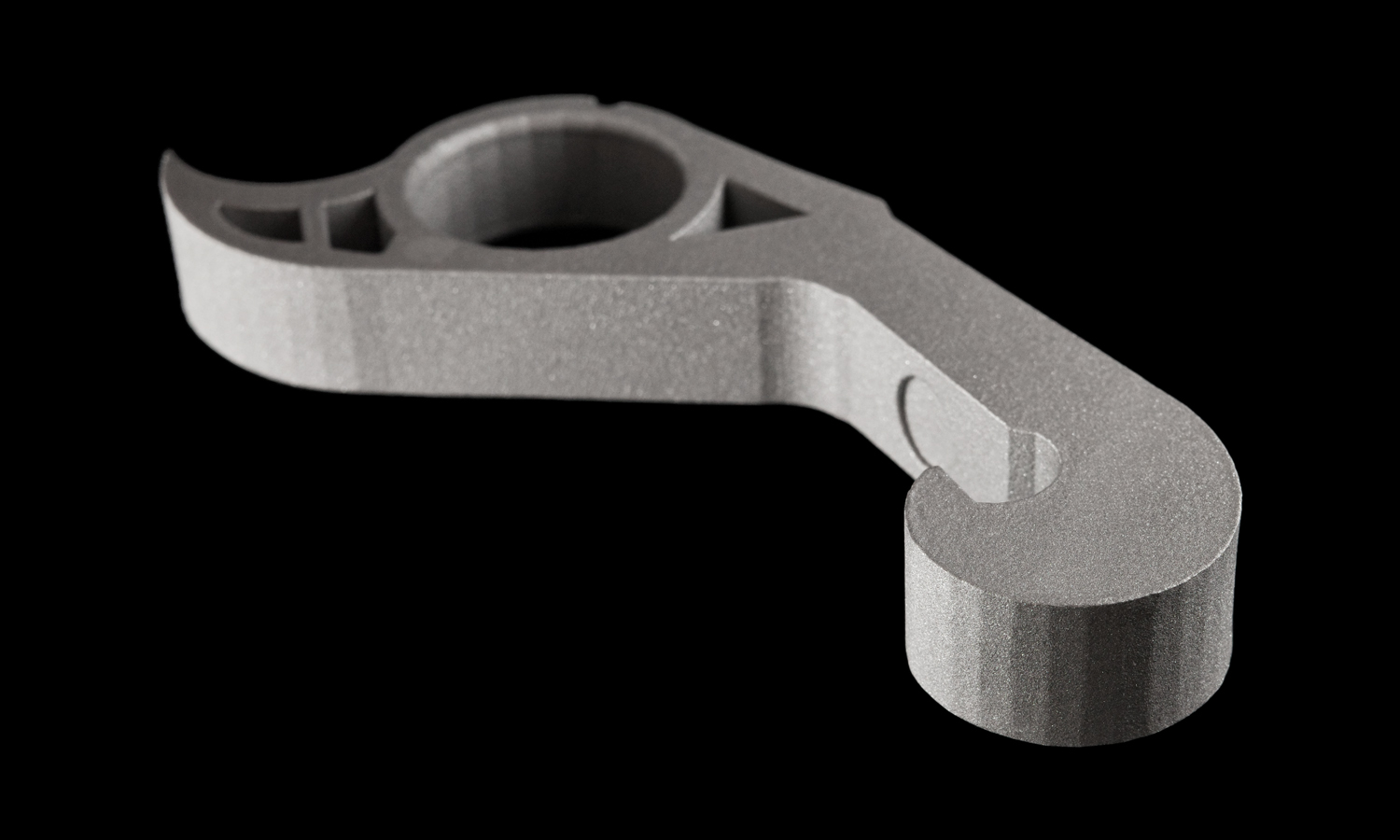

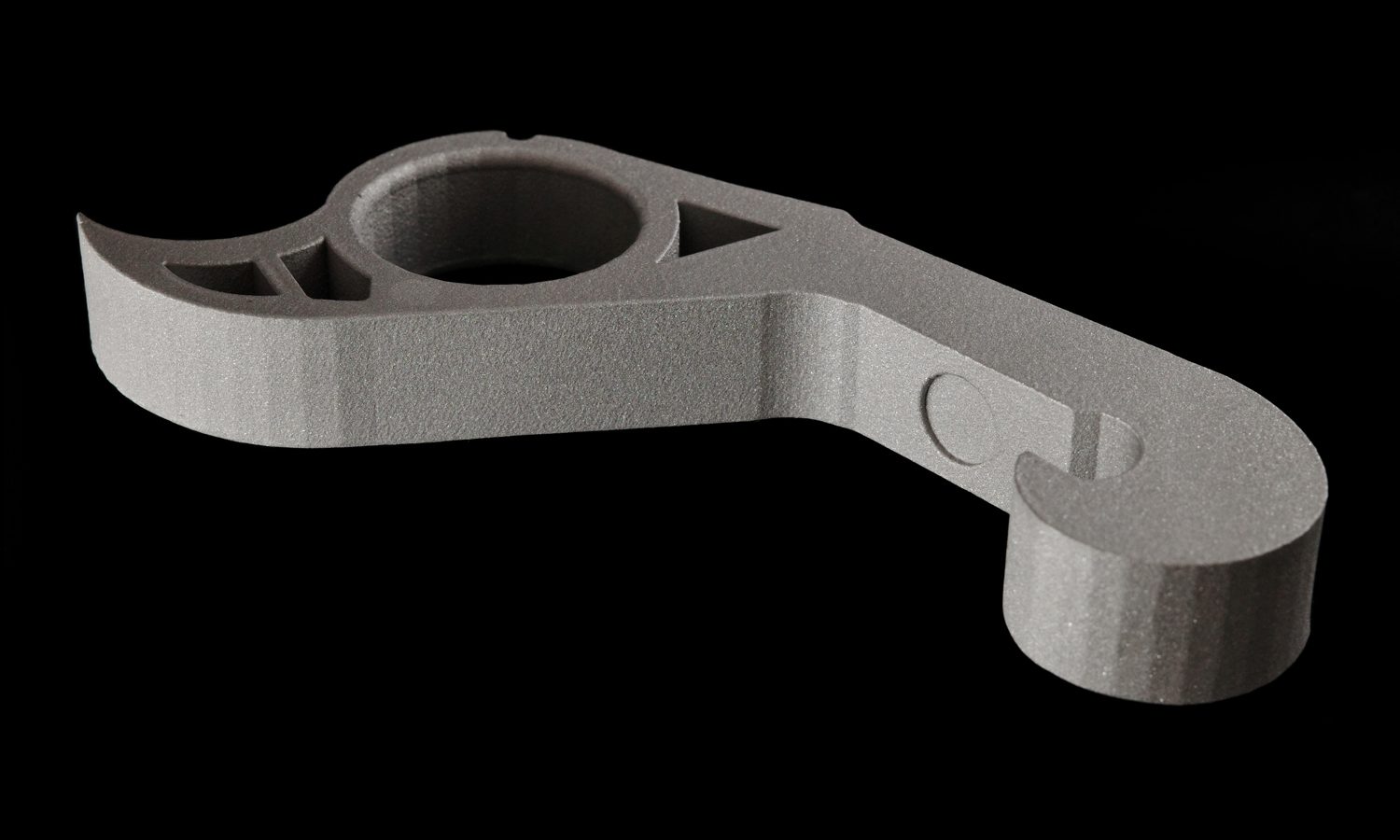

Have you ever wanted to open a beer bottle with just one hand? Well, now you can, thanks to this smart one-hand bottle opener that was 3D printed in aluminum 6061 using direct metal laser sintering (DMLS) technology.

This bottle opener is not only sleek and stylish, but also strong and durable. It was designed by Mark Manger, an Applied Artist from Denver, Colorado. Inspired by the stick & screw openers Mark encountered in Africa in the 1990‚Ä≤s, the GrOpener uses the same leverage principle, but in a form that allows a bottle to be opened through the act of grabbing it.¬Ý

The bottle opener is made of aluminum 6061, a popular alloy that combines high strength, low weight, and excellent corrosion resistance. Aluminum 6061 is widely used in aerospace, automotive, and biomedical industries, as well as for prototyping and manufacturing purposes.

To print this bottle opener, we used DMLS, a 3D printing process that uses a high-powered laser to fuse metal powder particles layer by layer. DMLS produces high-quality metal parts with complex geometries and fine details. DMLS also allows for greater design freedom and customization than traditional manufacturing methods.

You simply need to hold the bottle with your thumb, no name finger, and pinky finger. Then place one end of the opener under the cap, insert your index finger through the hole of the opener, and place your middle finger on the tail. Then, by using your middle finger to press the opener, the cap could be pried off with leverage.

This bottle opener is not only a handy tool, but also a great conversation starter. You can impress your friends with your one-hand skills and show them how cool 3D printing in aluminum 6061 is.

If you are interested in getting your own 3D printed aluminum 6061 bottle opener or any other metal part, you should check out FacFox’s aluminum 3D printing services. FacFox is a leading online platform that offers fast, reliable, and affordable 3D printing solutions for various industries and applications. FacFox can print yor parts in aluminum 6061 or other aluminum alloys using DMLS or other advanced technologies. You can upload your design, get an instant quote, and place your order online. FacFox will take care of the rest and deliver your parts to your doorstep in no time.

So what are you waiting for? Get your own DMLS 3D printed aluminum 6061 smart one-hand bottle opener today and enjoy your beer like never before! Cheers! üçª

Solution

- Step 1: A digital model of the bottle opener was downloaded from Thingiverse¬Ýand exported into a 3D printable file format (an STL format).

- Step 2: The STL file was imported into a DMLS 3D printer software and sliced into thin layers. The software also generated support structures to prevent deformation and warping during printing.

- Step 3: A layer of aluminum 6061 powder was spread evenly over the build platform of the DMLS 3D printer. A high-powered laser beam was directed to selectively fuse the powder particles together according to the cross-section of the first layer of the bottle opener.

- Step 4: The build platform was lowered by one layer thickness and another layer of powder was spread over it. The laser beam was again used to fuse the powder particles together, bonding them with the previous layer. This process was repeated until the bottle opener was fully formed.

- Step 5: The build platform was raised and the bottle opener was removed from the powder bed. The excess powder was recycled for future use.

- Step 6: The support structures were cut off from the bottle opener using a wire cutter or a saw. The bottle opener was then cleaned and polished to remove any rough edges or surface defects.

- Step 7: The bottle opener was subjected to a stress relief application to reduce residual stresses and improve mechanical properties.

- Step 8: The bottle opener was ready to use or undergo further post-processing if desired, such as coating, painting, or engraving.