- FDM 3D Printed Internal Combustion Engine Assembly Model

- SLA Clear High-temp Resin-100Ōäā 3D Printed Benchmark

Material Resin

Quantity 1 pcs

Price Range $1,000-5,000

Lead Time 12 workdays

Gallery

About Project

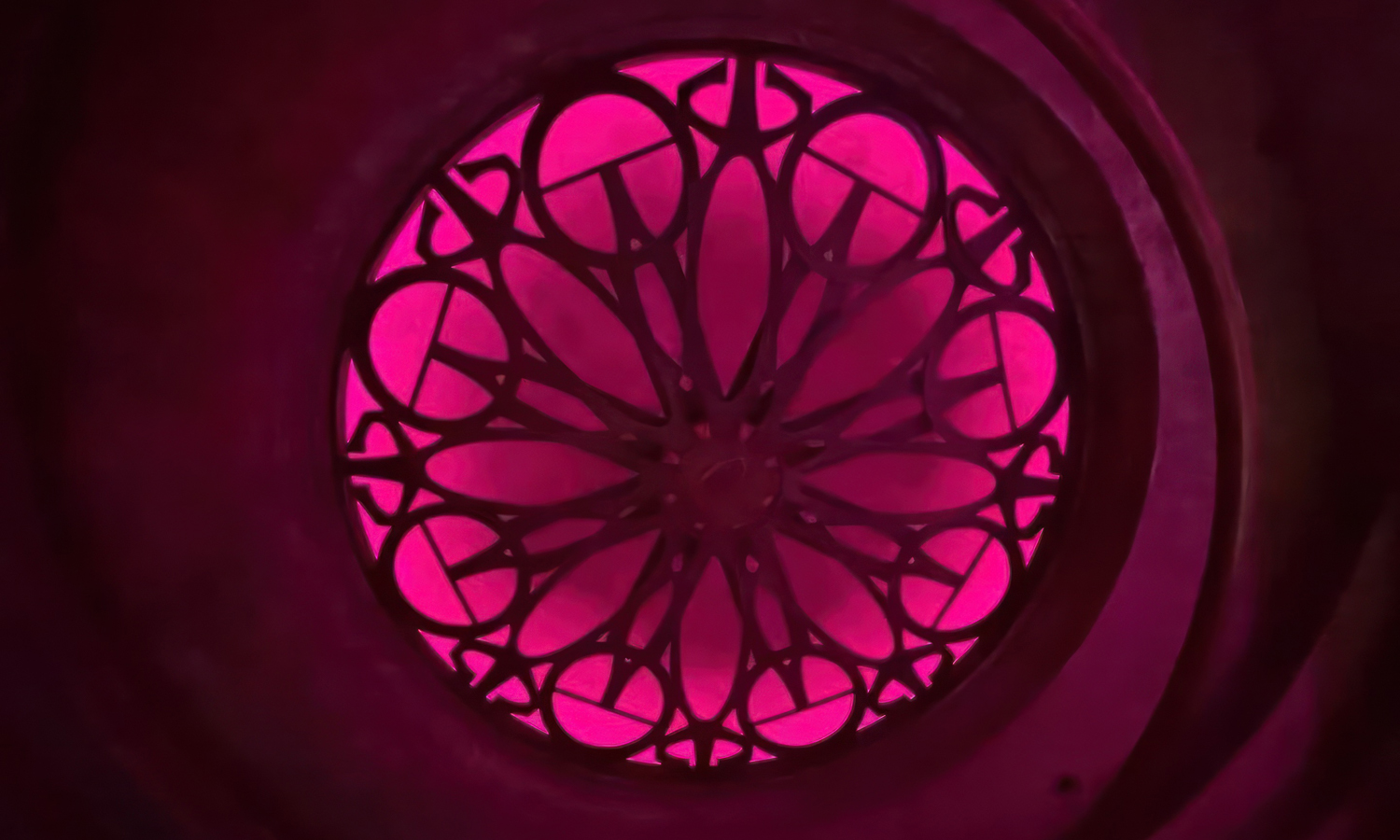

Behold the Celestial Wheel, a mesmerizing masterpiece that transforms any space into a realm of wonder. This stunning 3D-printed ceiling medallion, with its intricate geometric patterns and bold, bronze hue, is a testament to the power of additive manufacturing.

Inspired by the celestial bodies that dot the night sky, this circular design evokes a sense of wonder and mystery. Its intricate details, once the realm of skilled artisans, are now brought to life with the precision of 3D printing.

When illuminated, the Celestial Wheel comes alive, casting ethereal shadows and creating a captivating ambiance. The warm, inviting glow of the light source highlights the intricate details of the design, transforming it into a focal point that draws the eye and sparks conversation.

At a staggering 4.6 meters in diameter, this colossal piece required a unique approach. We divided the design into smaller sections, 3D printed each one, and then meticulously assembled them into a single, breathtaking work of art.

Pushing the Boundaries of 3D Printing

This Celestial Wheel is more than just a beautiful object; it’s a testament to the limitless potential of 3D printing. At FacFox, we specialize in large-format 3D printing, turning your wildest design dreams into tangible reality. From architectural marvels to artistic expressions, our advanced technology and expert team can bring your vision to life.

Ready to Reimagine Your Space?

Contact us today and let’s create something extraordinary together.

Solution

- Step 1: Initial Consultation. The designer approached FacFox with a concept for a large-scale, intricate ceiling medallion.

- Step 2: Material Recommendation and Quotation. FacFox provided recommendations for suitable 3D printing materials and a detailed quotation.

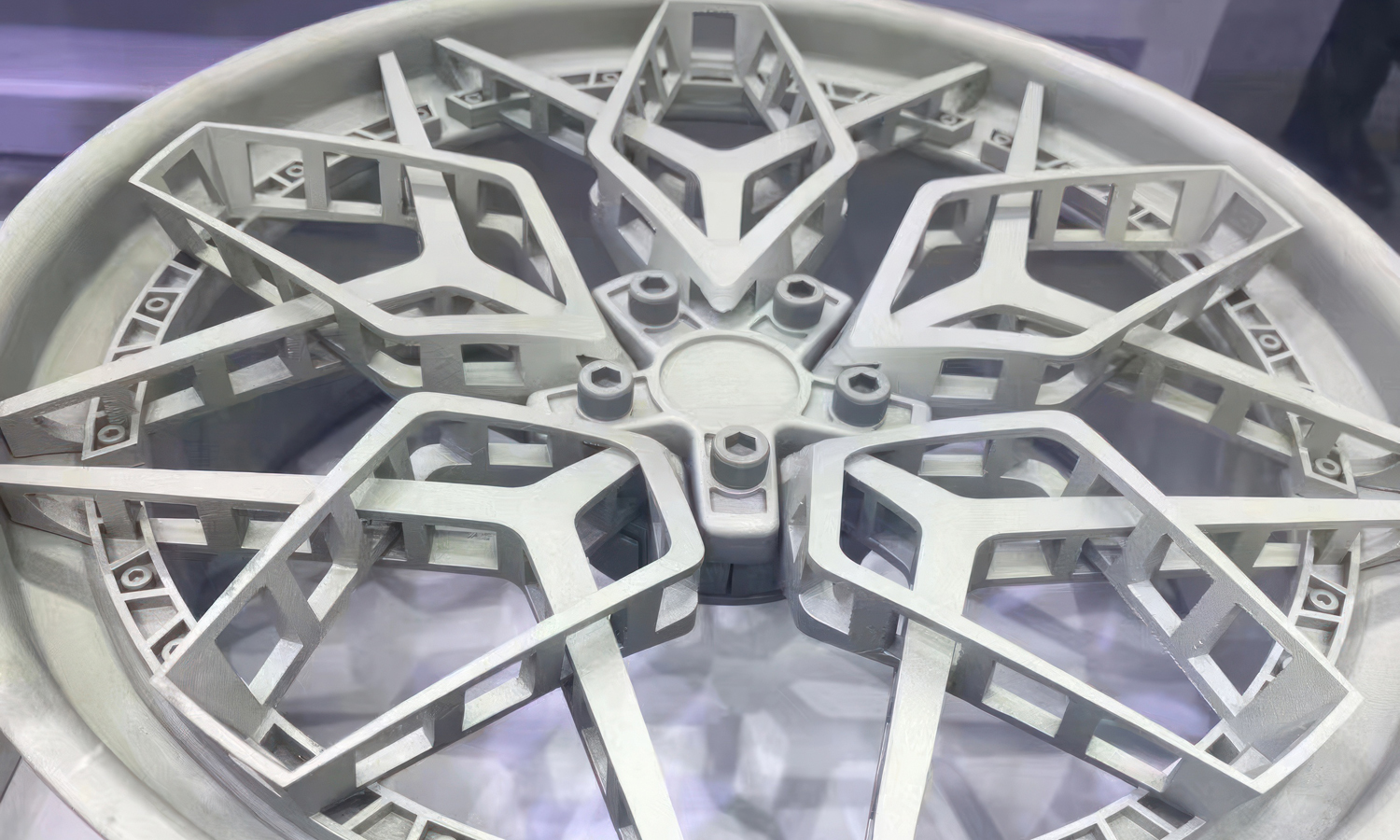

- Step 3: Design Analysis and Preparation. The 3D model was thoroughly examined and divided into smaller, more manageable sections to facilitate 3D printing.

- Step 4: 3D Printing. The individual sections were 3D printed using state-of-the-art technology.┬Ā SLA ABS-like Resin was chosen for its outstanding machinability, which allows tapping and threading.

- Step 5: Post-Processing. After printing, the parts underwent post-processing techniques such as cleaning, sanding, and surface finishing to achieve the desired aesthetic.

- Step 6: Assembly. The individual 3D-printed parts were carefully assembled to form the complete Celestial Wheel, and painted into appointed color.

- Step 7: Packaging and Shipping. The assembled medallion was securely packed in a wooden frame for safe transportation.

- Step 8: Installation. The interior decoration company installed the Celestial Wheel onto the ceiling, completing the final stage of the project.