- MJF 3D Print HP Nylon Citizens’ Scaled-down Group Statues

- DLP 3D Printed Ultra-detail Game Console Buttons for Molding

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 5 workdays

Gallery

About Project

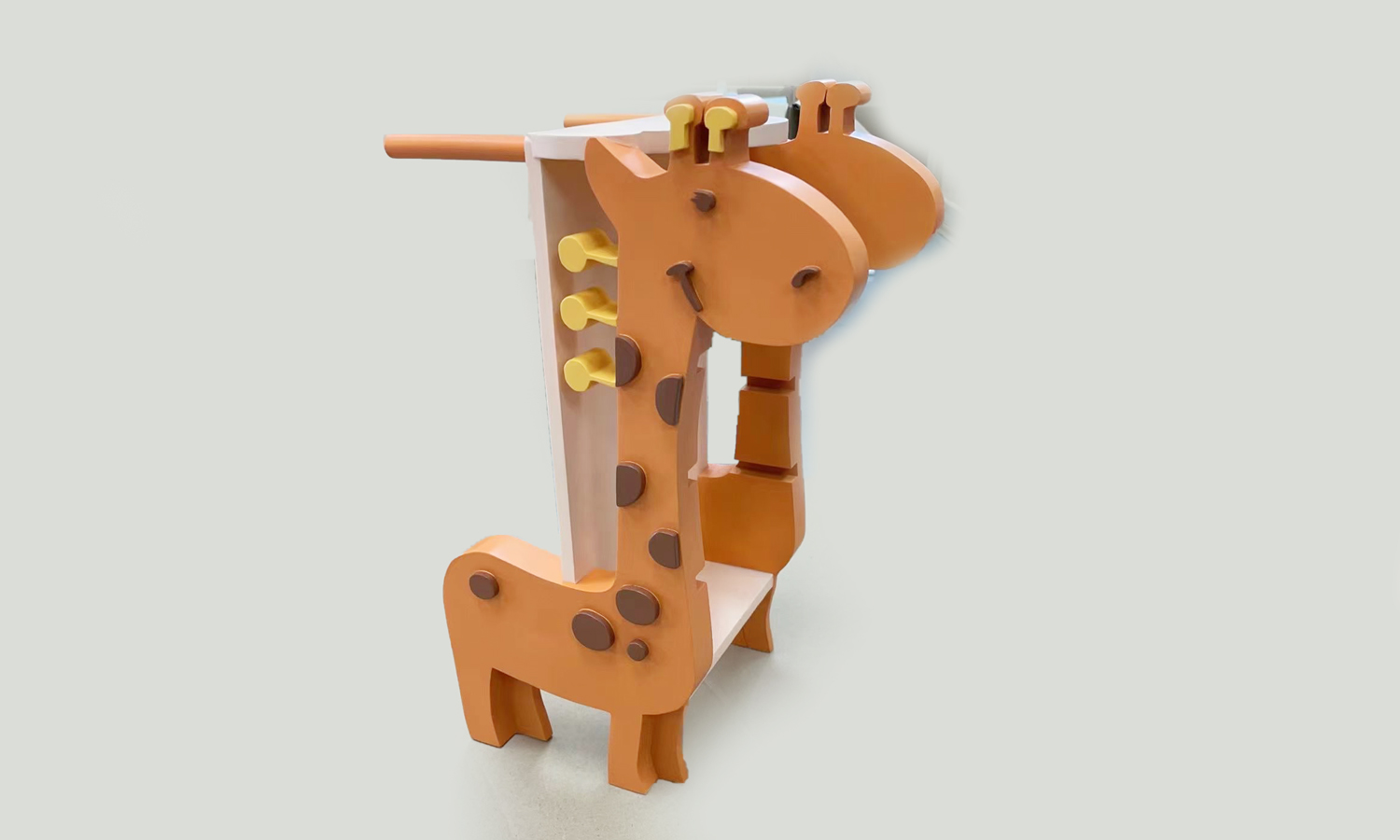

This adorable little guy is not only a great way to store your books, but he’s also a work of art. The giraffe is lovingly crafted from SLA Generic Resin and then hand-painted with vibrant colors. It has three shelves, perfect for your favorite books, toys, or knick-knacks. And to make sure it stays standing tall, he has two rods on his back that prop him up against the wall.

But the cutest part of all? This giraffe has some serious guitar swagger! Its neck is adorned with three tuning peg-like hairs, giving him a touch of rock and roll style.

Looking for a unique and eye-catching graduation project?

FacFox’s prototyping services are perfect for students who want to create something special. We can help you turn your wildest ideas into reality, using the latest 3D printing technology.

Here are just a few of the benefits of using FacFox for your graduation project:

- High-quality prints: We use only the best materials and equipment to ensure that your prints are flawless.

- Fast turnaround times: We know you’re on a deadline, so we’ll get your project to you quickly.

- Affordable prices: We offer competitive prices that won’t break the bank.

- Expert support: Our team of experts is here to help you every step of the way.

No matter what your needs are, FacFox has the prototyping solution for you.

Contact us today for a free quote!

Solution

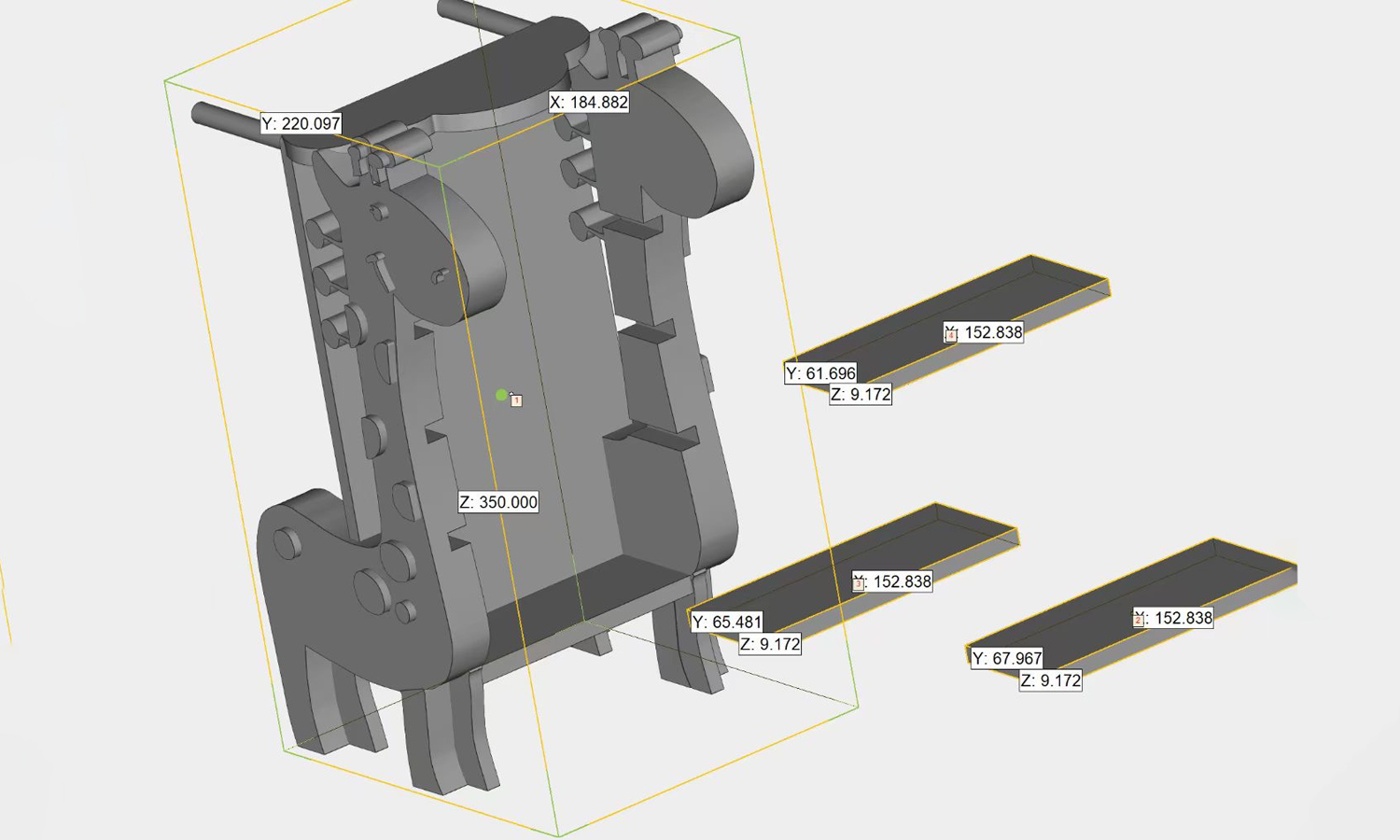

- Step 1: First, a digital sculptor, wielding the tools of 3D modeling software, breathed life into the giraffe’s whimsical form. Every curve, every guitar-inspired detail, was meticulously crafted in the virtual realm, laying the foundation for its physical manifestation.

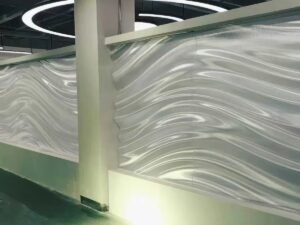

- Step 2: Once the digital model was complete, it was sliced into thin, horizontal layers by specialized software. These layers then served as the blueprint for the SLA 3D printer. A laser beam, guided by the digital blueprint, meticulously traced each layer onto a vat of liquid SLA Generic Resin, solidifying it into the giraffe’s charming form. Layer by layer, the bookcase emerged from the resin bath, a testament to the precision of additive manufacturing.

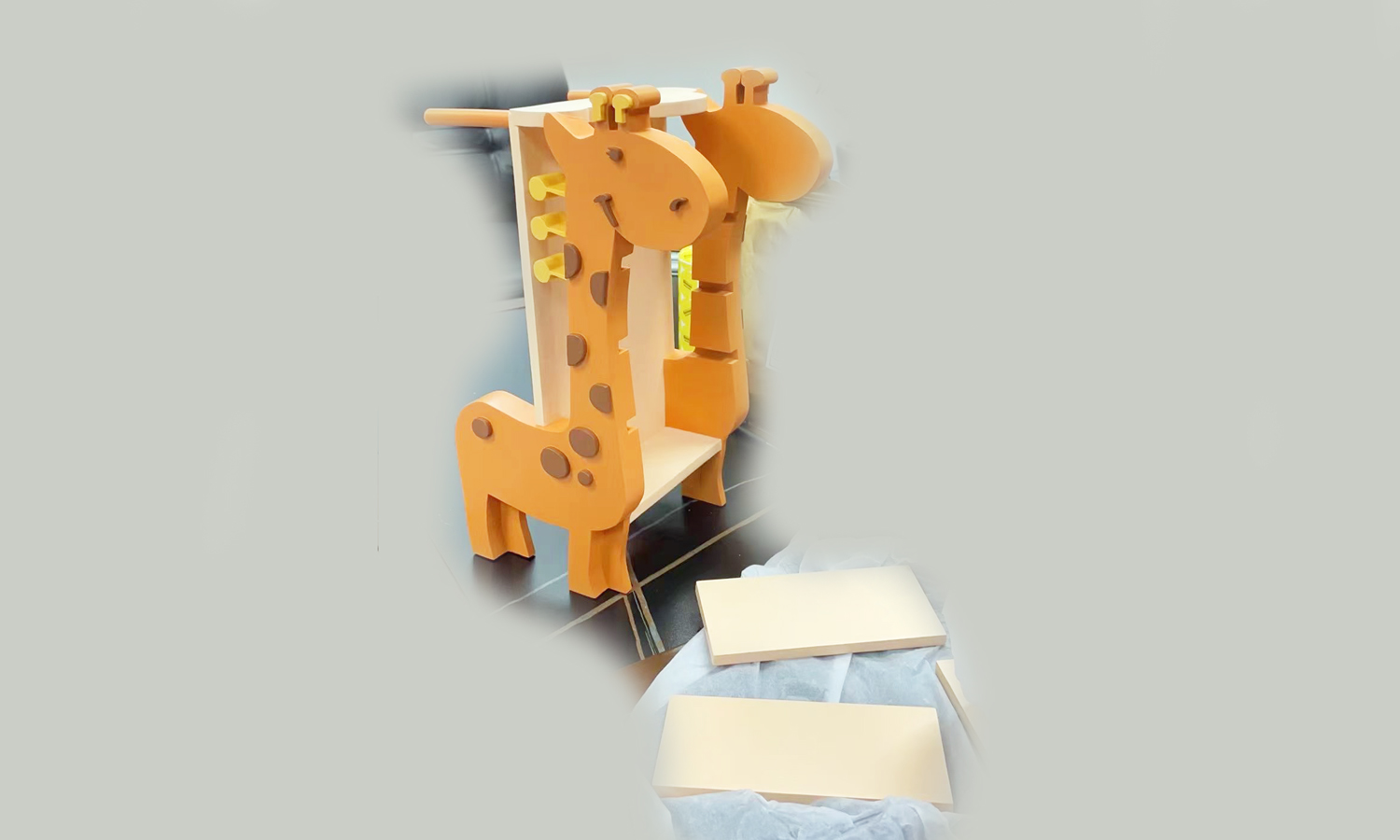

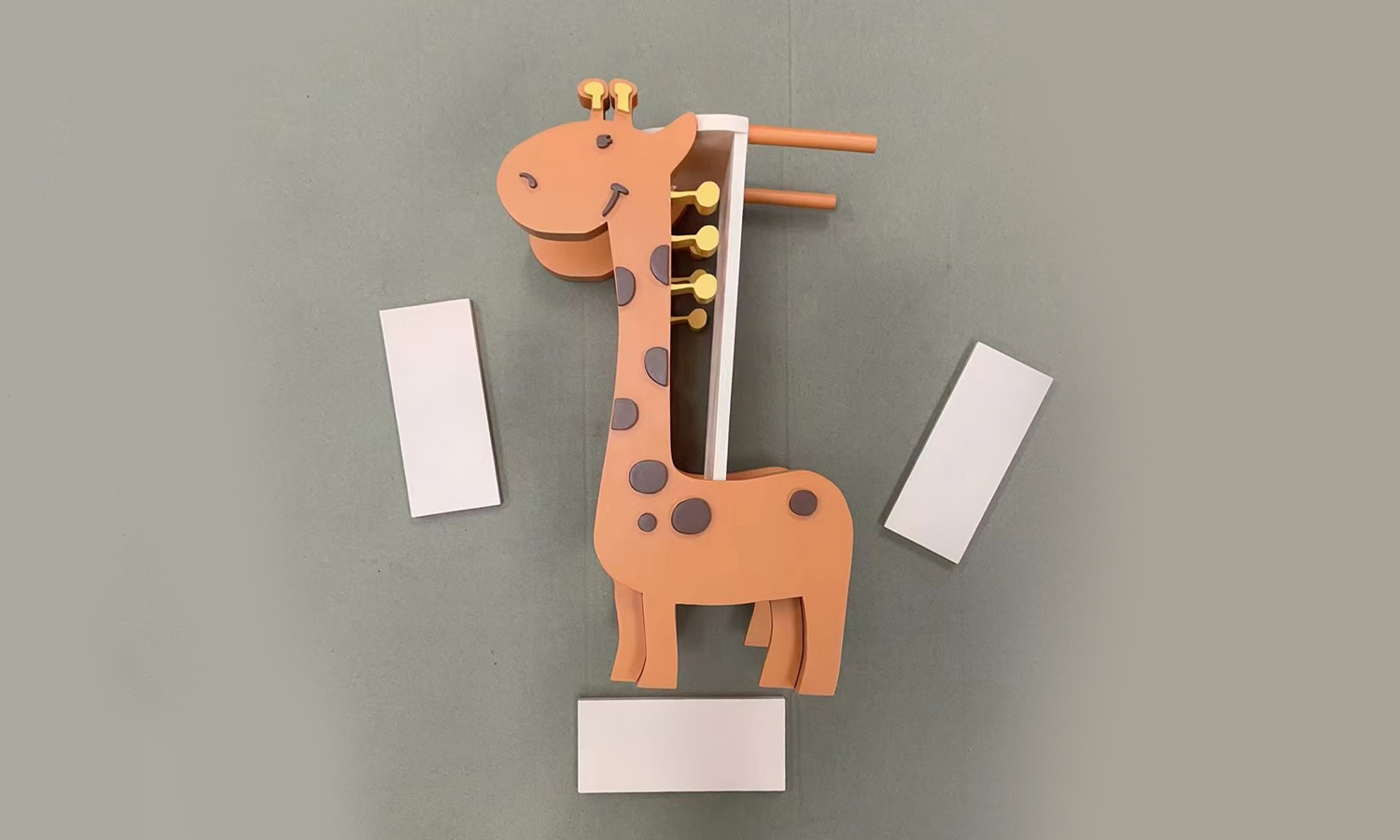

- Step 3: Freshly printed, the giraffe still held the marks of its birth. Skilled technicians carefully removed the support structures that had held its form during printing, leaving behind a smooth, albeit pale, surface. The resin remnants were then washed away, revealing the raw potential of the printed masterpiece.

- Step 4: To imbue the giraffe with its vibrant personality, a team of skilled artists took up their brushes and spray guns. Each color, meticulously chosen, was applied with a light touch, breathing life into the cartoon character. The guitar elements received special attention, their metallic accents adding a touch of rock and roll flair.

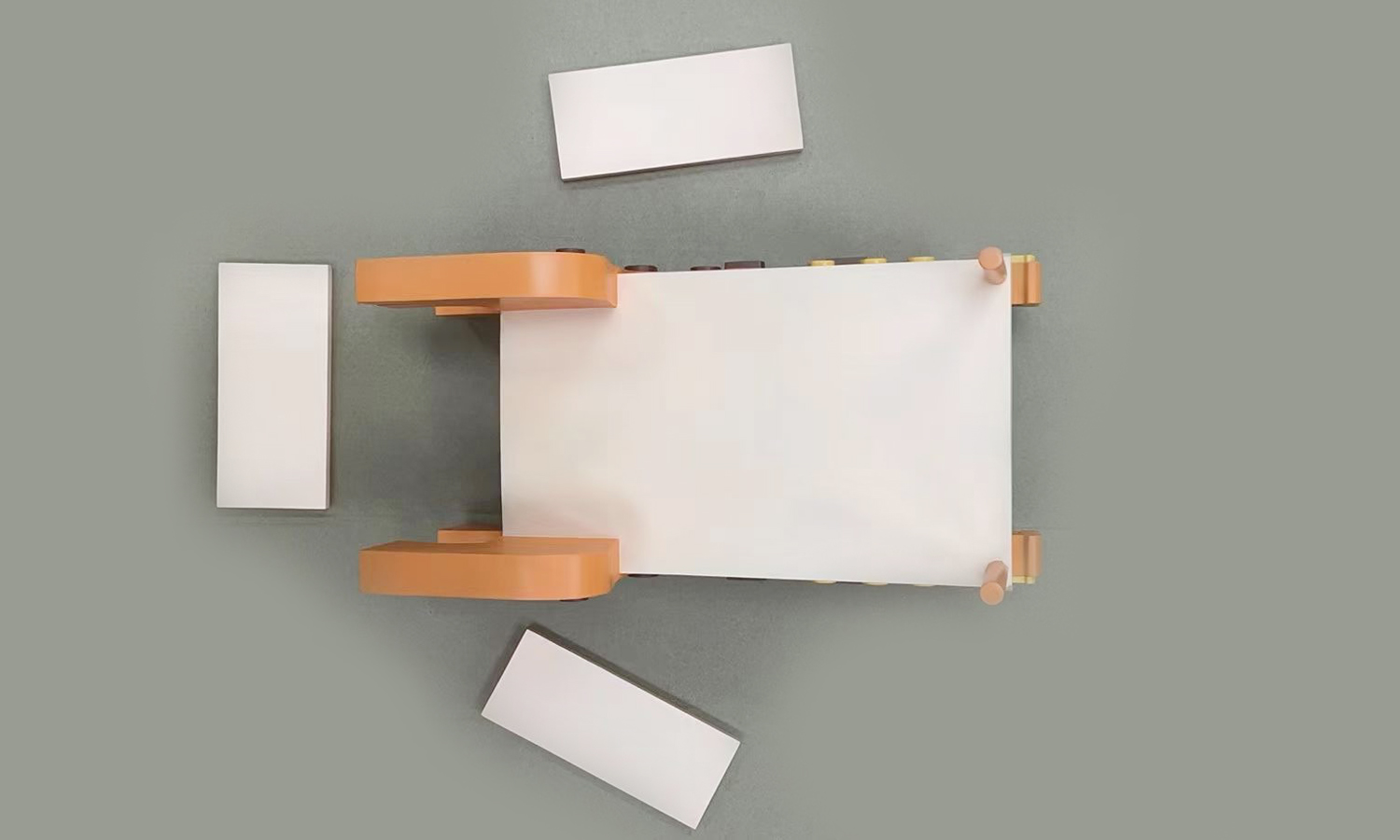

- Step 5: Finally, the individual components of the bookcase – the giraffe itself, the shelves, and the stabilizing rods – were carefully assembled. Each piece was meticulously positioned and secured, ensuring the structural integrity of the whimsical creation.