- PolyJet 3D Printed Full-color Henry Fox Miniature

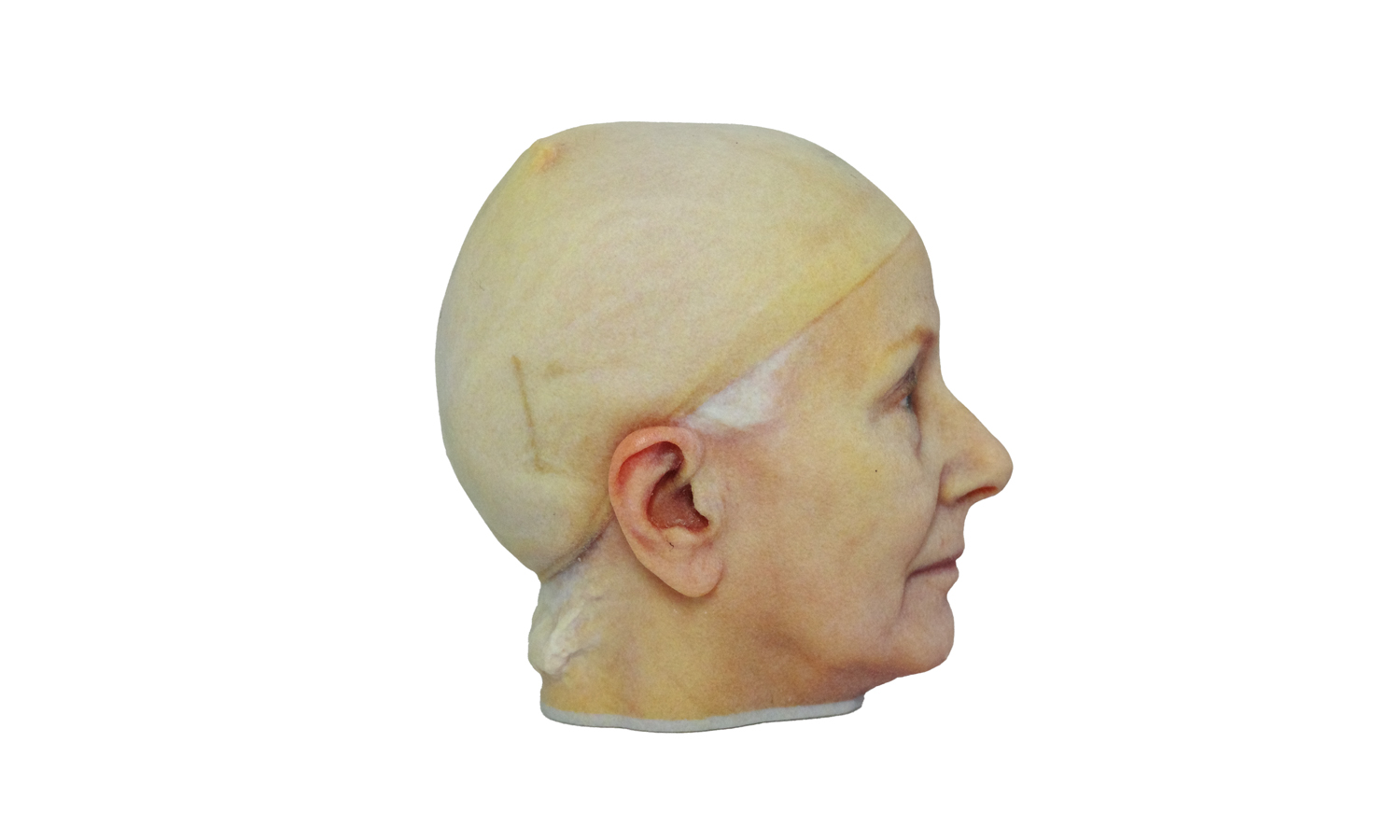

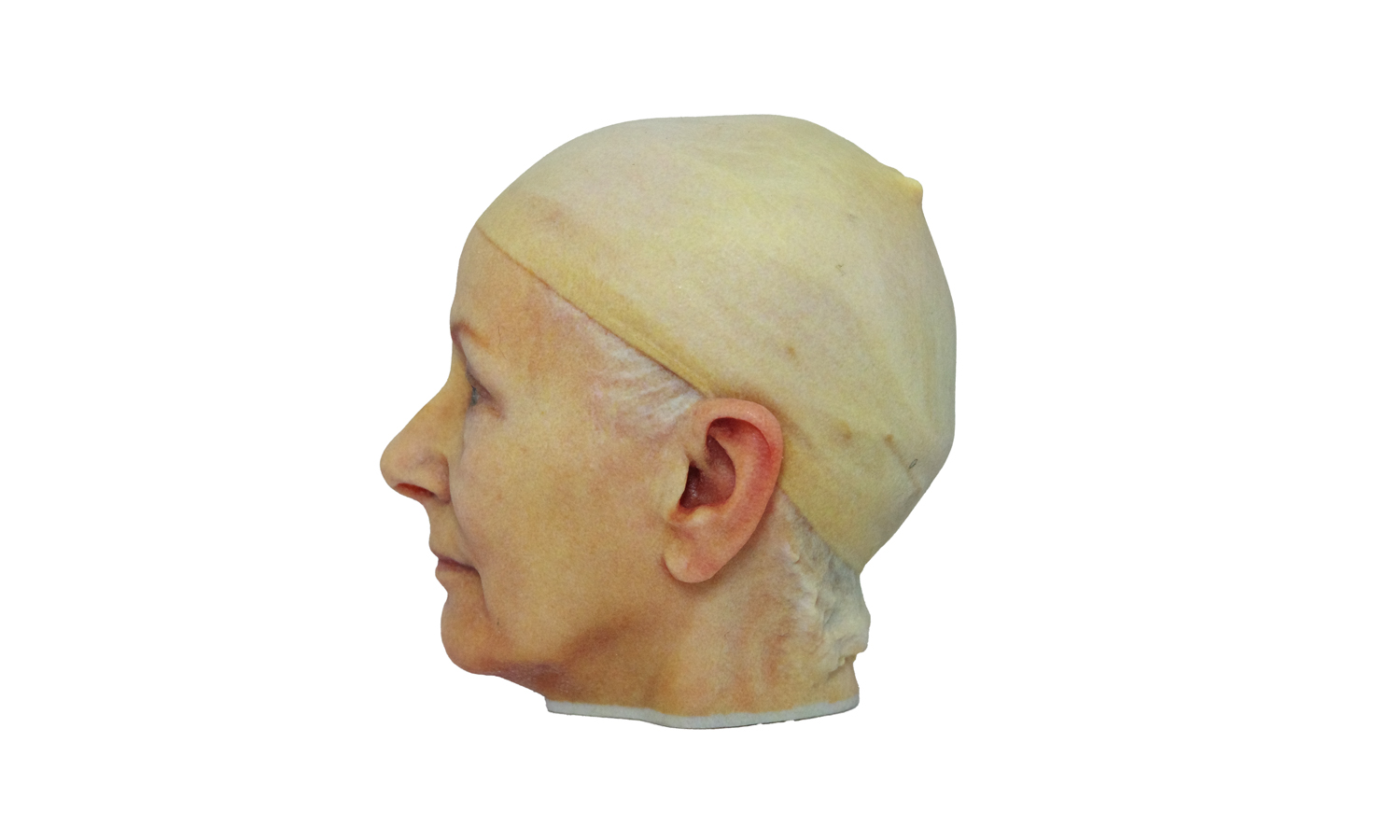

- PolyJet 3D Printed Full-color Elder Man Head Miniature

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

This full-color miniature head of an older woman was created using PolyJet 3D printing technology. As you can see, the colors are somewhat muted, with a lower saturation and darker tones. The skin tone has a subtle yellowish-greenish tint, which adds to the realism of the piece.

Printing Quality Evaluation

Taking a closer look, the printing quality is impressive. The PolyJet technology captures fine details, including the wrinkles and skin texture. The color gradients are smooth, and the layering is barely visible, resulting in a high-quality surface finish. The technology’s ability to reproduce subtle color variations is also evident in the realistic skin tone.

PolyJet Capabilities

PolyJet 3D printing is known for its ability to create parts with a wide range of colors and materials. It can produce smooth, detailed surfaces and is ideal for creating realistic prototypes, models, and end-use parts. The technology works by jetting layers of liquid photopolymer onto a build tray and curing them with UV light. This allows for the creation of complex geometries and intricate designs.

FacFox’s PolyJet 3D Printing Service

If you’re looking for high-quality, full-color 3D printing services, consider FacFox. They offer PolyJet 3D printing, ensuring your project benefits from this technology’s capabilities. Their expertise and advanced equipment can bring your ideas to life with exceptional detail and color accuracy.

Solution

- Step 1: A digital 3D model of the elder woman’s head was created using computer-aided design (CAD) software.

- Step 2: The 3D model was then prepared for printing by slicing it into numerous thin layers.

- Step 3: A PolyJet 3D printer was loaded with the necessary photopolymer resins in various colors.

- Step 4: Layer by layer, the photopolymer materials were jetted onto the build platform. Simultaneously, UV light was used to cure and solidify each layer immediately after deposition.

- Step 5: This process was repeated, with each subsequent layer being precisely placed and cured on top of the previous one, gradually building the full three-dimensional object.

- Step 6: Once the printing process was complete, the build platform was removed from the printer.

- Step 7: Support structures, which were automatically generated during the printing process to support overhanging features, were carefully removed from the printed head.

- Step 8: The printed full-color elder woman head miniature was then post-processed, which may have involved cleaning to remove any residual support material or un-cured resin.

- Step 9: A final inspection of the printed miniature was conducted to ensure quality and accuracy.